Lighting Electronics | 2007/08 - National Lamps and Components

Lighting Electronics | 2007/08 - National Lamps and Components

Lighting Electronics | 2007/08 - National Lamps and Components

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

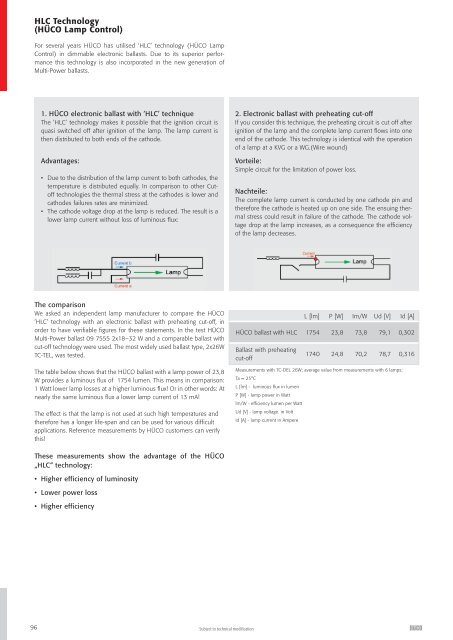

HLC Technology(HÜCO Lamp Control)For several years HÜCO has utilised ‘HLC’ technology (HÜCO LampControl) in dimmable electronic ballasts. Due to its superior performancethis technology is also incorporated in the new generation ofMulti-Power ballasts.1. HÜCO electronic ballast with ’HLC’ techniqueThe ’HLC’ technology makes it possible that the ignition circuit isquasi switched off after ignition of the lamp. The lamp current isthen distributed to both ends of the cathode.Advantages:• Due to the distribution of the lamp current to both cathodes, thetemperature is distributed equally. In comparison to other Cutofftechnologies the thermal stress at the cathodes is lower <strong>and</strong>cathodes failures rates are minimized.• The cathode voltage drop at the lamp is reduced. The result is alower lamp current without loss of luminous flux:2. Electronic ballast with preheating cut-offIf you consider this technique, the preheating circuit is cut off afterignition of the lamp <strong>and</strong> the complete lamp current flows into oneend of the cathode. This technology is identical with the operationof a lamp at a KVG or a WG.(Wire wound)Vorteile:Simple circuit for the limitation of power loss.Nachteile:The complete lamp current is conducted by one cathode pin <strong>and</strong>therefore the cathode is heated up on one side. The ensuing thermalstress could result in failure of the cathode. The cathode voltagedrop at the lamp increases, as a consequence the efficiencyof the lamp decreases.The comparisonWe asked an independent lamp manufacturer to compare the HÜCO’HLC’ technology with an electronic ballast with preheating cut-off, inorder to have verifiable figures for these statements. In the test HÜCOMulti-Power ballast 09 7555 2x18–32 W <strong>and</strong> a comparable ballast withcut-off technology were used. The most widely used ballast type, 2x26WTC-TEL, was tested.The table below shows that the HÜCO ballast with a lamp power of 23,8W provides a luminous flux of 1754 lumen. This means in comparison:1 Watt lower lamp losses at a higher luminous flux! Or in other words: Atnearly the same luminous flux a lower lamp current of 13 mA!The effect is that the lamp is not used at such high temperatures <strong>and</strong>therefore has a longer life-span <strong>and</strong> can be used for various difficultapplications. Reference measurements by HÜCO customers can verifythis!L [lm] P [W] Im/W Ud [V] Id [A]HÜCO ballast with HLC 1754 23,8 73,8 79,1 0,302Ballast with preheatingcut-off1740 24,8 70,2 78,7 0,316Measurements with TC-DEL 26W; average value from measurements with 6 lamps;Ta = 25°CL [lm] - luminous flux in lumenP [W] - lamp power in Wattlm/W - efficiency lumen per WattUd [V] - lamp voltage. in VoltId [A] - lamp current in AmpereThese measurements show the advantage of the HÜCO„HLC“ technology:• Higher efficiency of luminosity• Lower power loss• Higher efficiency96 Subject to technical modification