- Page 1 and 2: The Safety HandbookExperience - Sys

- Page 3 and 4: IntroductionWe develop innovative p

- Page 5 and 6: Our products revolutionise the mark

- Page 7 and 8: Jokab Safetys developments of the 8

- Page 9 and 10: The Machinery Directive; for machin

- Page 11 and 12: Protection or warning?How is it pos

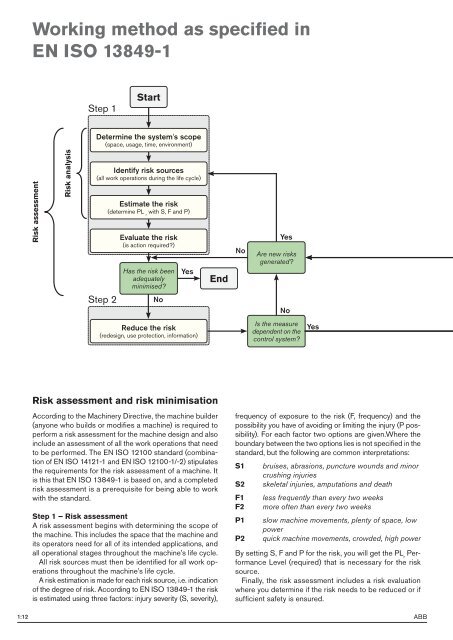

- Page 13: New standards for safety incontrol

- Page 17 and 18: CategoryThe structure for the compo

- Page 19 and 20: Theoretical approach for multiple m

- Page 21 and 22: A mechanical switch doesnot give a

- Page 23 and 24: Training in risk analysisWe regular

- Page 25 and 26: ContentsPage1Why you should use the

- Page 27 and 28: - to supervise safety devices!Light

- Page 29 and 30: 1Pluto B46Pluto AS-i246 I/OSafe bus

- Page 31 and 32: Technical info - PlutoDynamic signa

- Page 33 and 34: Technical data - generalManufacture

- Page 35 and 36: Input connectionThe system offers s

- Page 37 and 38: Technical data - generalManufacture

- Page 39 and 40: Certificates12345678910111213ABB2:1

- Page 41 and 42: Electrical connections1234567891011

- Page 43 and 44: Pluto 1 settings - Machine cabinet1

- Page 45 and 46: 2:21ABB1234567891011131412

- Page 47 and 48: 2:23ABB1234567891011131412

- Page 49 and 50: Technical data - GATE-P2Manufacture

- Page 51 and 52: Technical data - GATE-D2Manufacture

- Page 53 and 54: Technical data - GATE-C2Manufacture

- Page 55 and 56: Technical data - GATE-E2Manufacture

- Page 57 and 58: Technical data - Safe Encoder RSA 5

- Page 59 and 60: Safe EncoderFunction block for a si

- Page 61 and 62: ContentsPage1Why should I use the b

- Page 63 and 64: How does the bus system AS-Interfac

- Page 65 and 66:

1Easy connections to the AS-i cable

- Page 67 and 68:

Technical information - Pluto AS-iI

- Page 69 and 70:

Technical data - generalManufacture

- Page 71 and 72:

Why should you usesafety node Urax?

- Page 73 and 74:

Technical data - Urax-A1/A1RManufac

- Page 75 and 76:

Technical data - Urax-B1RManufactur

- Page 77 and 78:

Technical data - Urax-C1 and C1RMan

- Page 79 and 80:

Technical data - Urax-D1RManufactur

- Page 81 and 82:

Technical data - Urax-E1Manufacture

- Page 83 and 84:

12345678910111213ABB3:2314

- Page 85 and 86:

ContentsPage1Pluto Manager ________

- Page 87 and 88:

List of standards and special funct

- Page 89 and 90:

ContentsPage1Safety system - Dynami

- Page 91 and 92:

Vital is available in three variant

- Page 93 and 94:

Number of Tinas that can be used wi

- Page 95 and 96:

How does a dynamic circuit of Vital

- Page 97 and 98:

Vital 1 Safety controller1Dynamicci

- Page 99 and 100:

Technical data - Vital 1Manufacture

- Page 101 and 102:

Three connection alternativesAccord

- Page 103 and 104:

Operating mode M1 - Separate functi

- Page 105 and 106:

Technical data - Vital 2Manufacture

- Page 107 and 108:

Operating mode M1 - Separate functi

- Page 109 and 110:

Technical data - Vital 3Manufacture

- Page 111 and 112:

Tinais available in several version

- Page 113 and 114:

Adaptation unitTina 2A/BTina 2A/B i

- Page 115 and 116:

Connection blockTina 4ATina 4A is a

- Page 117 and 118:

Bypassing of Eden and Tina units.If

- Page 119 and 120:

Adaptation unitTina 7ATina 7A is a

- Page 121 and 122:

Connection examples of safety senso

- Page 123 and 124:

Technical data - Tina 10A/B/CManufa

- Page 125 and 126:

Terminal blockTina 12ATina 12A is a

- Page 127 and 128:

1Example of safety sensors connecti

- Page 129 and 130:

HA3300A-01 Connection example Vital

- Page 131 and 132:

HA3303A Vital 1 with emergency stop

- Page 133 and 134:

HA3306D Vital 1 with 3 lightbeams S

- Page 135 and 136:

HE3811B-01 Safety light beam Spot w

- Page 137 and 138:

HE3824F-01 Eden and 2 bypass lightb

- Page 139 and 140:

HH3302D Vital 1 with Tina 8A and di

- Page 141 and 142:

HB0006A Vital with 4 Eden units + R

- Page 143 and 144:

HB0003A Pluto with Smile and Inca e

- Page 145 and 146:

12345678910111213ABB5:5714

- Page 147 and 148:

ContentsPage1Why should you use Saf

- Page 149 and 150:

The most flexible safety relayson t

- Page 151 and 152:

1Technical dataSafety categorySafet

- Page 153 and 154:

Technical information - RT6InputsTh

- Page 155 and 156:

Technical data - RT6ManufacturerArt

- Page 157 and 158:

Technical information - RT7 A/BInpu

- Page 159 and 160:

ABBTechnical data - RT7 A/BManufact

- Page 161 and 162:

Technical information - RT9InputsTh

- Page 163 and 164:

Technical data - RT9ManufacturerABB

- Page 165 and 166:

ABBTechnical data - JSBRT11Manufact

- Page 167 and 168:

Technical data - JSBR4ManufacturerA

- Page 169 and 170:

Technical data - JSBT4ManufacturerT

- Page 171 and 172:

Technical data - BT50(T)Manufacture

- Page 173 and 174:

Technical data - BT51(T)Conductor w

- Page 175 and 176:

Technical data - JSBT5(T)Manufactur

- Page 177 and 178:

Technical data - JSHT1 A/BManufactu

- Page 179 and 180:

Technical data - JSHT2 A/B/CManufac

- Page 181 and 182:

Technical data - E1TManufacturerArt

- Page 183 and 184:

Technical data - JSR1TManufacturerA

- Page 185 and 186:

Technical data - JSR2AManufacturerA

- Page 187 and 188:

Technical data - JSR3TManufacturerT

- Page 189 and 190:

HA5400A Connection examples JSBR412

- Page 191 and 192:

HA6501B Connection examples BT50T12

- Page 193 and 194:

HA7600A Connection examples RT61234

- Page 195 and 196:

HA7900A Connection examples RT91234

- Page 197 and 198:

HG7636B Focus light grid/curtain wi

- Page 199 and 200:

HG7654A Interlocked door with RT6 a

- Page 201 and 202:

HG7674B Safety interlock switch JSN

- Page 203 and 204:

HL7600B Several JSNY7 connected to

- Page 205 and 206:

HP7600B Machine control-Isolation o

- Page 207 and 208:

HB0008A Focus light curtain/light b

- Page 209 and 210:

ContentsPage1Why use light beams/li

- Page 211 and 212:

Light grids for long distancesLight

- Page 213 and 214:

Muting(bypassing)Automatic bypassin

- Page 215 and 216:

Cycle initiation withlight curtain1

- Page 217 and 218:

Safety distance for light beams acc

- Page 219 and 220:

are activated. If for example durin

- Page 221 and 222:

12FII-4-K2-500 FII-4-K4-zzzz D FII-

- Page 223 and 224:

Muting (bypassing)- Focus II12Built

- Page 225 and 226:

Muting with FMC and FMI units1234Th

- Page 227 and 228:

Muting sensors - Mute RRetro-reflec

- Page 229 and 230:

Muting with Mute R and Mute D1A sol

- Page 231 and 232:

Technical data - BjornManufacturer:

- Page 233 and 234:

Blanking programmerBP1- a quick way

- Page 235 and 236:

HR7000C-01 Focus - Connection witho

- Page 237 and 238:

HR7000H-01 Focus - Connection with

- Page 239 and 240:

HR7000L-01 Tina 10A, 10B and 10C co

- Page 241 and 242:

HR7000Q Cable connection example123

- Page 243 and 244:

Mounting and alignment - SpotSafety

- Page 245 and 246:

Connection of Spot T/R to Vital1123

- Page 247 and 248:

Software - Look scannerFunction but

- Page 249 and 250:

12345678910111213ABB7:4114

- Page 251 and 252:

ContentsPage1Stopping time ________

- Page 253 and 254:

Stopping time and MachineDiagnosis

- Page 255 and 256:

Saving• Select measurement series

- Page 257 and 258:

SM5 1250/2500 Linear sensorThe SM5

- Page 259 and 260:

ContentsPage1Why should you use sen

- Page 261 and 262:

Eden -highest safety level and reli

- Page 263 and 264:

Application examples - EdenEden to

- Page 265 and 266:

Technical data - EdenManufacturerAr

- Page 267 and 268:

Technical data - JSNY5ManufacturerA

- Page 269 and 270:

13Technical data - JSNY7Manufacture

- Page 271 and 272:

Technical data - JSNY8ManufacturerA

- Page 273 and 274:

Technical data - JSNY9Utilisation c

- Page 275 and 276:

Models and accessoris - MagneHandle

- Page 277 and 278:

Dimensions - Magne123Dimensions Mag

- Page 279 and 280:

Connection example - Magne 1 in ser

- Page 281 and 282:

Modular structure - Dalton1. Choose

- Page 283 and 284:

Dimensions - Dalton1234Bracket 1 wi

- Page 285 and 286:

Connection example - Dalton M12 and

- Page 287 and 288:

Knox in 4 different states1OpenRese

- Page 289 and 290:

Technical data - KnoxMakeSafety lev

- Page 291 and 292:

Connection example - Knox with down

- Page 293 and 294:

ContentsPage1Why should control dev

- Page 295 and 296:

12Two-channel all the way out to th

- Page 297 and 298:

Highest safety levelwhether the but

- Page 299 and 300:

Available combinations of bottom- a

- Page 301 and 302:

Connection example - Three-position

- Page 303 and 304:

Connection with bottom parts AE1234

- Page 305 and 306:

Technical data - SafeballManufactur

- Page 307 and 308:

Electrical connection - SafeballTwo

- Page 309 and 310:

For mobile installation12JSTD25F/JS

- Page 311 and 312:

Connection example - JSTD25P-11234D

- Page 313 and 314:

Technical data - JSTD20Manufacturer

- Page 315 and 316:

ContentsPage1Why do you need an Eme

- Page 317 and 318:

Emergency stop for enclosureinstall

- Page 319 and 320:

Technical data - INCA 1/INCA 1 Tina

- Page 321 and 322:

Connection examples - SmileSmile 10

- Page 323 and 324:

Technical data - SmileManufacturer:

- Page 325 and 326:

Connection examples - Smile TinaSmi

- Page 327 and 328:

Technical data - Smile TinaManufact

- Page 329 and 330:

Technical data - Smile AS-iManufact

- Page 331 and 332:

Technical data - Stop-LineManufactu

- Page 333 and 334:

Ordering data - Stop-Line accessori

- Page 335 and 336:

Reset buttonSmile 11RWhen do I need

- Page 337 and 338:

ContentsPage1When shall I use conta

- Page 339 and 340:

Safety contact rails GP - General1T

- Page 341 and 342:

Mounting and electrical connection

- Page 343 and 344:

Standard shapes1Shape AShape BCusto

- Page 345 and 346:

Technical Data - Safety MatsManufac

- Page 347 and 348:

Electrical connection - Safety cont

- Page 349 and 350:

12345678910111213ABB 12:1314

- Page 351 and 352:

ContentsPage1Guick-Guard ® fencing

- Page 353 and 354:

A flexible and stable fencing syste

- Page 355 and 356:

Quick-Guard ® is supplied in three

- Page 357 and 358:

Quick-Guard ® E- can be ordered in

- Page 359 and 360:

IMAGE DESIGNATION ART.NO. DESCRIPTI

- Page 361 and 362:

Quick-Guard ® Assembly, standard v

- Page 363 and 364:

Dimensions for aluminum profile len

- Page 365 and 366:

Designation: JSM A8888Article numbe

- Page 367 and 368:

Cable tieDesignation: JSM X1Article

- Page 369 and 370:

Small Angle fitting, e.g. Electrica

- Page 371 and 372:

DOOR COMPONENTSTo mount conventiona

- Page 373 and 374:

Designation: JSM D18 HandleArticle

- Page 375 and 376:

Upper Door bolt1Upper Door boltDesi

- Page 377 and 378:

Sliding bolt for Eden1Designation:

- Page 379 and 380:

Guide Components for Sliding Door1G

- Page 381 and 382:

FITTINGS FOR SWITCHES1Eden fittings

- Page 383 and 384:

Fittings for Interlock Switches JSN

- Page 385 and 386:

ACCESSORIESAll fittings and door co

- Page 387 and 388:

18-12SteelplateCross-bent sheet met

- Page 389 and 390:

FunctionHighest protection in accor

- Page 391 and 392:

ContentsPage1Declaration of conform

- Page 393 and 394:

Declaration of conformity - JSBR4Ot

- Page 395 and 396:

Declaration of conformity - Eden, T

- Page 397 and 398:

Declaration of conformity- KnoxOthe

- Page 399 and 400:

NotesABB 14:9

- Page 401:

NotesABB 14:11