Install/Operation - Thermal Products Inc

Install/Operation - Thermal Products Inc

Install/Operation - Thermal Products Inc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

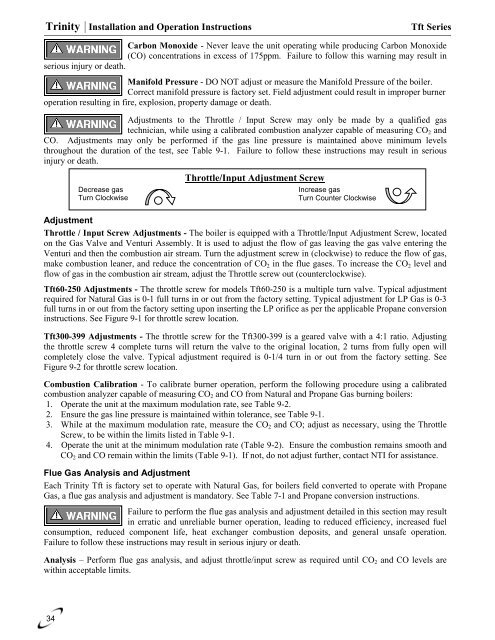

Trinity │<strong>Install</strong>ation and <strong>Operation</strong> InstructionsTft SeriesCarbon Monoxide - Never leave the unit operating while producing Carbon Monoxide(CO) concentrations in excess of 175ppm. Failure to follow this warning may result inserious injury or death.Manifold Pressure - DO NOT adjust or measure the Manifold Pressure of the boiler.Correct manifold pressure is factory set. Field adjustment could result in improper burneroperation resulting in fire, explosion, property damage or death.Adjustments to the Throttle / Input Screw may only be made by a qualified gastechnician, while using a calibrated combustion analyzer capable of measuring CO 2 andCO. Adjustments may only be performed if the gas line pressure is maintained above minimum levelsthroughout the duration of the test, see Table 9-1. Failure to follow these instructions may result in seriousinjury or death.Decrease gasTurn ClockwiseThrottle/Input Adjustment Screw<strong>Inc</strong>rease gasTurn Counter ClockwiseAdjustmentThrottle / Input Screw Adjustments - The boiler is equipped with a Throttle/Input Adjustment Screw, locatedon the Gas Valve and Venturi Assembly. It is used to adjust the flow of gas leaving the gas valve entering theVenturi and then the combustion air stream. Turn the adjustment screw in (clockwise) to reduce the flow of gas,make combustion leaner, and reduce the concentration of CO 2 in the flue gases. To increase the CO 2 level andflow of gas in the combustion air stream, adjust the Throttle screw out (counterclockwise).Tft60-250 Adjustments - The throttle screw for models Tft60-250 is a multiple turn valve. Typical adjustmentrequired for Natural Gas is 0-1 full turns in or out from the factory setting. Typical adjustment for LP Gas is 0-3full turns in or out from the factory setting upon inserting the LP orifice as per the applicable Propane conversioninstructions. See Figure 9-1 for throttle screw location.Tft300-399 Adjustments - The throttle screw for the Tft300-399 is a geared valve with a 4:1 ratio. Adjustingthe throttle screw 4 complete turns will return the valve to the original location, 2 turns from fully open willcompletely close the valve. Typical adjustment required is 0-1/4 turn in or out from the factory setting. SeeFigure 9-2 for throttle screw location.Combustion Calibration - To calibrate burner operation, perform the following procedure using a calibratedcombustion analyzer capable of measuring CO 2 and CO from Natural and Propane Gas burning boilers:1. Operate the unit at the maximum modulation rate, see Table 9-2.2. Ensure the gas line pressure is maintained within tolerance, see Table 9-1.3. While at the maximum modulation rate, measure the CO 2 and CO; adjust as necessary, using the ThrottleScrew, to be within the limits listed in Table 9-1.4. Operate the unit at the minimum modulation rate (Table 9-2). Ensure the combustion remains smooth andCO 2 and CO remain within the limits (Table 9-1). If not, do not adjust further, contact NTI for assistance.Flue Gas Analysis and AdjustmentEach Trinity Tft is factory set to operate with Natural Gas, for boilers field converted to operate with PropaneGas, a flue gas analysis and adjustment is mandatory. See Table 7-1 and Propane conversion instructions.Failure to perform the flue gas analysis and adjustment detailed in this section may resultin erratic and unreliable burner operation, leading to reduced efficiency, increased fuelconsumption, reduced component life, heat exchanger combustion deposits, and general unsafe operation.Failure to follow these instructions may result in serious injury or death.Analysis – Perform flue gas analysis, and adjust throttle/input screw as required until CO 2 and CO levels arewithin acceptable limits.34