WR10168 SSV Bro/single pp - cedip

WR10168 SSV Bro/single pp - cedip

WR10168 SSV Bro/single pp - cedip

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

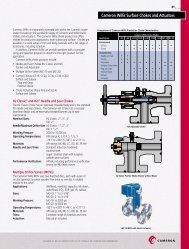

Cameron Willis Self-ContainedEmergency Shutdown SystemsReliable ESD Protection from the Wellhead to the Flowline

Cameron Willis Self-Contained Emergency Shutdown SystemsCameron Willis Self-Contained Emergency Shutdown(ESD) Systems are used to hydraulically actuate gatevalves in remote locations. As the nameimplies, these systems are totally self-contained andoperate as ESD to automatically shut-in productionin an emergency situation. Such systemsare ideal for use in on production wellheadsor pipelines in remote locationssuch as deserts, rain forests, arctic environments,jungles or any area wheresupervision is minimal or no additionalpower source is available.Cameron Willis Self-Contained ESDSystems feature reliable, field-proven CameronWillis Saf-T-Gard hydraulic actuators mounted onCameron FLS gate valves. The Cameron Willis controlsystem contains the sensors and hydraulic powersource necessary to close the valve when an abnormalcondition detected. For example, whenthe system is in automatic mode and flowlinepressure increases above or below the pressuresensors “high” or “low” settings,the system automaticallycloses the valve and shuts in thewell.Or, if a fire occurs, the eutectic on the fusible plug meltsand the system automatically closes the valve and shuts in thewell. The system can also be operated in manual mode wheresimple operation of a needle valve opens or closes the valve.Cameron Willis Self-Contained ESD Systems are availablein 1-13/16” through 7” nominalvalve sizes and workingpressures up to15,000 psi. Two versionsare available, a<strong>single</strong> pump and adouble pump typewhich can be used whencontrol of a mastervalve and subsurface safety valve (<strong>SSV</strong>) is required fromone control box. Options include actuator-mounted orstand-mounted installation, enclosed panel or non-enclosedpanel, anti-theft shroud, panel-mounted or field-mountedpressure sensors, electric position indicators and firstoutindicators. In addition, fusible plugs are availablein temperature ranges 160°F, 212°F and 283° F. Solarpowered pneumatic and solar poweredhydraulic systems are also available.Features and Benefits• System incorporates reliable, field-proven Cameron FLSgate valves, Cameron Willis Saf-T-Gard actuators andcontrol panel from a <strong>single</strong> source.• Automatic control for master valves and subsurfacesafety valves provides safety in remote locations.• Self-contained power source is ideal for remote areas,wells without power, or sites with minimal supervision.• Available in <strong>single</strong>-and double-pump configurations tocontrol a <strong>single</strong> gate valve or a gate valve and <strong>SSV</strong>.• Closed loop hydraulic circuitry ensures contaminantfree,long lasting su<strong>pp</strong>ly of operating fluid.• Field-proven in extreme warm and cold environments.• High/low pressure sensors provide flowline pressuremonitoring to preset values.• Hydraulic accumulator accommodates temperatureinduced volume changes of the fluid contained in theclosed circuit.• Fusible plug ensures shutdown in case of fire.• All components housed in secure stainless steel enclosurewhich meets the requirements for operation inhazardous locations without the need to purge the box.• Control panel can be mounted to the actuator or toa nearby stand to accommodate a variety of fieldsituations.

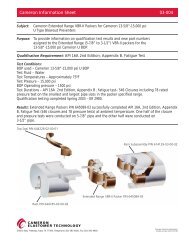

N 2Self-Contained <strong>SSV</strong> and SC<strong>SSV</strong> Control SystemsOperating ProcedurePlace (K-1) the hydraulic dump valve in bypass, by turningthe handle in the bypass position. Hand pump (B-1) tothe required actuator operating pressure. This pressure can beseen on pressure gauge (E-1). When the flowline pressure isbetween the low (F-1) ad the high (G-1) pressure sensor setpoints, the 100 regulated pressure from (C-1), which can beseen on pressure gauge (D-1) will flow through the low sensor(G-1) and high sensor (F-1) allowing the 100 psi to hold(K-1) hydraulic dump valve closed. Now take (K-1) out ofbypass by turning the handle to the in-service position. Thesystem is now in service. If an ESD, fire, or PSHL occurs,the pilot pressure from (K-1) dump valve will be removed,allowing (K-1) to dump the fluid from the actuator back intothe reservoir, closing the surface safety valve (<strong>SSV</strong>).Self-Contained <strong>SSV</strong> Control SystemStandard ArrangementN-1 J -1A-1B-1A. Suction StrainerB. Hand PumpC. RegulatorD. Pressure Gauge,0-200 psiE. Pressure Gauge,0-6000 psiSet @5,000 psiESDPull toShut InP-1 K-1Set @150 PSISet @100 PSIH -1Material ListC -1PSL900 PSIPre-ChargeF. High Pressure SensorG. Low Pressure SensorH. Relief ValveJ. ESD ValveK. 2 Way N.O. DumpValve with ManualOverrideG -1M -1F -1E-1PSHL-1 FusiblePlug6T6T6TD-1FlowlineSense<strong>SSV</strong>L. Hydraulic Fusible PlugM. 5000 psi AccumulatorN. Filler/BreatherP. Relief ValveSelf -Contained <strong>SSV</strong> and SC<strong>SSV</strong> 5000 psi Control SystemStandard ArrangementSelf -Contained <strong>SSV</strong> and SC<strong>SSV</strong> 10,000 psi Control SystemStandard ArrangementN-1ESDPull toShut InJ-1Set @150 psiSet @100 psiH-1C-1PSLG-1 F-1PSHD-1Flowline6T SenseL-1 FusibleN-1ESDPull toShut InJ-1Set @150 psiSet @100 psiH-1C-1PSLG-1 F-1PSHD-1Flowline6T SenseL-1 FusibleA-1B-1R-1P-1Set @5,000 psiSet @5,000 psiP-2K-2K-1S-1Q-1900 psiPre-Charge900 psiPre-ChargeN 2N 2M-1M-2E-1E-26T Plug<strong>SSV</strong>6TSC<strong>SSV</strong>4TA-1 A-2B-1B-1P-1Set @5,000 psiSet @10,000 psiP-2K-2K-1S-1Q-1900 psiPre-Charge900 psiPre-ChargeN 2N 2M-1M-2E-1E-26T Plug<strong>SSV</strong>6TSC<strong>SSV</strong>4TMaterial ListMaterial ListA. Suction StrainerB. Hand PumpC. RegulatorD Pressure Gauge,0-200 psiE. Pressure Gauge,0-6000 psiF. High Pressure SensorG. Low Pressure SensorH. Relief ValveJ. ESD ValveK. 2 Way N.O. DumpValve with ManualOverrideL. Hydraulic Fusible PlugM. 5000 psi AccumulatorN. Filler/BreatherP. Relief ValveQ. Flow ControlR. 3-Way ValveS. Low PressureAccumulatorA. Suction StrainerB. Hand PumpC. RegulatorD. Pressure Gauge,0-200 psiE. Pressure Gauge,0-6000 psiF. High Pressure SensorG. Low Pressure SensorH. Relief ValveJ. ESD ValveK. 2 Way N.O. DumpValve with ManualOverrideL. Hydraulic Fusible PlugM. 5000 psi AccumulatorN. Filler/BreatherP. Relief ValveQ. Flow ControlR. 10,000 psi Hand PumpS. Low PressureAccumulator

<strong>SSV</strong> Control PanelThe control system for a typical Cameron Willis Self-Contained ESD System is incorporated into a 316 stainlesssteel enclosure with a mounting bracket. Connectorsare mounted on the side of the panel for ease of installationin virtually any field layout.A typical controls system enclosure includes the followingcomponents: Hydraulic hand pump to provide thenecessary output pressure to the actuator. Closed loophydraulic circuitry for maintenance of hydraulic pressure.Hydraulic accumulator with 900 psi nitrogen pre-chargefor thermal expansion. Relief valves on both high pressureand low pressure hydraulic circuits. ESD valve foremergency shutdown. Pressure gauges to monitor outputpressures for the high pressure and low pressure circuit.<strong>SSV</strong> Control Panel Features1006014040 16020 1800200psi30002000 400010000psi50006000Item Schematic NameReference431PLOTPRESSUREPLOTPRESSUREPLOTPRESSUREIN SERVICE2<strong>SSV</strong>PRESSUREPILOT MODE5 SELECTOR 6ESOPULL TO CLOSEHANDPUMP1 D-1 Pilot Pressure2 E-1 <strong>SSV</strong> Pressure3 K-1 Turn Clockwise to Override Pilots4 K-1 Turn Counterclockwise forNormal OperationLOWPILOTHIGHPILOTPILOT SUPPLYREGULATOR7 8 9105 Q-1 Pilot Mode Sector In-Service/Test6 J-1 ESD Pull to Close7 G-1 Low Pilot8 F-1 High Pilot9 C-1 Pilot Su<strong>pp</strong>ly Regulator10 B-1 Hand PumpTypical Cameron-Willis ESD Control SystemFusiblePlugEMERGENCYSHUTDOWNESD StationControlPanelActuatorBonnetSense LineNeedle ValveWing ValveFlow LineCameron-Willis ESD System wit Pole-Mounted Control PanelControlling Single <strong>SSV</strong>The Cameron Willis self-poweredcontrol system provides ahydraulic power to remote areas.

Western HemisphereCameronPO Box 1212Houston, Texas 77251-1212Tel 713 939 2211Fax 713 939 2620Cameron Willis10810 N.W. FreewayHouston, Texas 77092Tel 713 683 4600Fax 713 683 4350Eastern HemisphereCooper Cameron (U.K.) Ltd.5 Mondial WayHarlingtonHayes, UB3 5ARTel 011 44 181 990 1800Fax 011 44 181 990 1888Cameron WillisAghafad, LongfordRepublic of IrelandHayes, UB3 5ARTel 011 353 43 45301Fax 011 353 43 41560Asia Pacific/Middle EastCooper Cameron (Singapore) Pte, Ltd.No. 2 Gul Circle, Jurong Industrial EstLocked Bag Service No. 3Jurong Town Post OfficeSingaporeRepublic of SingaporeTel 65 8613355Fax 65 8616197Cameron Willis5003 93rd StreetEdmonton, Alberta T6E 559Tel 65 8613355Fax 65 8616197Visit our website atwww.camerondiv.com©Cooper Cameron Corporation, Cameron Division, Printed in USA 12/00, OP/5M, <strong>WR10168</strong>/TC1440