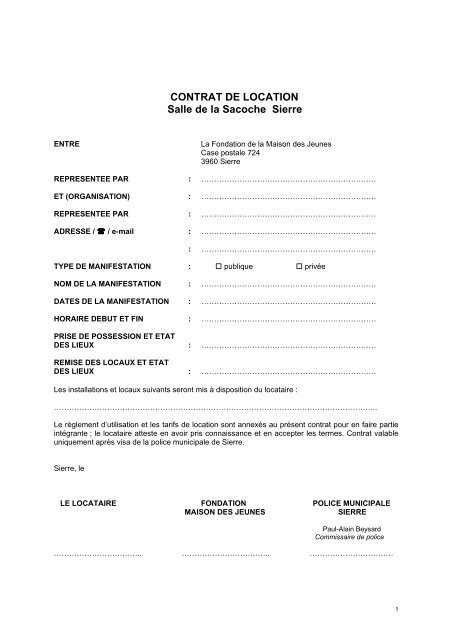

CONTRAT DE LOCATION Salle de la Sacoche Sierre

CONTRAT DE LOCATION Salle de la Sacoche Sierre

CONTRAT DE LOCATION Salle de la Sacoche Sierre

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

REGLEMENT D’UTILISATIONArticle 1Préjudice <strong>de</strong> fortuneLa Fondation <strong>de</strong> <strong>la</strong> Maison <strong>de</strong>s Jeunes n’assume aucune responsabilité si, pour quelque raison que ce soit, l’état<strong>de</strong> l’infrastructure ne permet pas à <strong>la</strong> manifestation projetée d’avoir lieu, entraînant un préjudice <strong>de</strong> fortune parl’organisateur (billets vendus, etc.).Article 2Etat <strong>de</strong>s lieuxUn état <strong>de</strong>s lieux se fera lors <strong>de</strong> <strong>la</strong> remise <strong>de</strong>s clefs, signé par les parties.Article 3Remise <strong>de</strong>s clefsDès 2005, une personne responsable <strong>de</strong> <strong>la</strong> salle remettra les clefs, effectuera avec le locataire le contrôle <strong>de</strong>slocaux, ce même contrôle sera exécuté lors <strong>de</strong> <strong>la</strong> restitution <strong>de</strong>s locaux ; pour cette prestation, il sera perçu unmontant <strong>de</strong> Fr. 50.-, montant qui sera prélevé sur le dépôt <strong>de</strong> garantie.Article 4MatérielLes locaux sont remis au locataire, propres, les chaises étant empilées à l’endroit assigné. La salle dispose <strong>de</strong>260 chaises.Article 5LocationLe prix <strong>de</strong> location convenu est <strong>de</strong> Fr. ( cents) et un dépôt <strong>de</strong> garantie <strong>de</strong> Fr. ( cents) est <strong>de</strong>mandé ; lemontant total <strong>de</strong> Fr. est payable à <strong>la</strong> signature du contrat auprès <strong>de</strong> l’UBS SA <strong>Sierre</strong>, compte 268-H5300361.0.Article 6ChargesDans le prix <strong>de</strong> location sont incluses les charges d’électricité et <strong>de</strong> chauffage.Article 7Entretien et nettoyageLes locaux seront restitués, propres, les chaises étant empilées à l’endroit assigné ; l’état <strong>de</strong>s lieux sera contrôléet contresigné.Si le nettoyage n’était pas fait, ce travail sera effectué par du personnel <strong>de</strong> nettoyage, facturé au prix <strong>de</strong> Fr. 25.-par heure.Article 8Dépôt <strong>de</strong> garantieLe montant du dépôt <strong>de</strong> garantie sera restitué au locataire, sous déduction <strong>de</strong>s éventuels frais <strong>de</strong> nettoyage ou<strong>de</strong> réparation <strong>de</strong>s dégâts causés.Visa du locataire …………………………2

J. Fornell et al. / Scripta Materialia 62 (2010) 13–16 15Figure 2. Depen<strong>de</strong>nce of hardness on the nanoin<strong>de</strong>ntation maximumload for (a) several pieces of the as-cast sample and (b) several pieces ofthe compressed specimen. The inset in (a) is a scanning electronmicroscopy image of an in<strong>de</strong>ntation performed on the as-cast specimenusing a maximum load of 500 mN.matrix. The second ring in the SAED pattern, markedwith an arrow (inset Fig. 1b), indicates the formationof a crystalline phase that may be the tetragonal Zr 2 Ni(space group I4/mcm, a = 0.649 nm and c = 0.527 nm).Therefore, our results indicate that <strong>de</strong>formation promotesnanocrystallization. It should be noted that Denget al. [27] also presented a direct high-resolution TEMobservation of nanocrystallization in a Zr–Al–Ni–CuBMG fractured by compression test. They suggestedthat, due to the concentration of p<strong>la</strong>stic flow, the loca<strong>la</strong>tomic neighbor distance increases producing nanocrystallizationin the amorphous structure. Other authorshave obtained evi<strong>de</strong>nce for nanocrystallization in shearbands [28,29]. The temperature increase associated with<strong>de</strong>formation is c<strong>la</strong>imed to p<strong>la</strong>y a role in the formation ofnanocrystals.In or<strong>de</strong>r to better un<strong>de</strong>rstand the <strong>de</strong>formation behaviorin this metallic g<strong>la</strong>ss, nanoin<strong>de</strong>ntation tests were performedat different maximum loads (P max ), both in theas-cast and the compressed specimen. Generally, in bulkmetallic g<strong>la</strong>sses, hardness is expected to <strong>de</strong>crease whenthe in<strong>de</strong>ntation <strong>de</strong>pth increases. This effect is usuallyreferred to as the in<strong>de</strong>ntation size effect [30–35] and isattributed to the softening caused by <strong>de</strong>formation-inducedcreation of free volume. In the present study (Fig. 2), hardnessof the as-cast alloy is found to <strong>de</strong>crease for P max <strong>la</strong>rgerthan 100 mN. However, it is interesting to remark that anincrease of hardness is observed when in<strong>de</strong>ntations wereperformed at lower loads (see Fig. 2a).To elucidate the physical origin of this mechanicalhar<strong>de</strong>ning, TEM specimens from the as-cast alloy, containingan array of nanoin<strong>de</strong>nts, were prepared. Figure3a is an SEM image showing a hole (created during ionmilling of the TEM sample preparation) surroun<strong>de</strong>d byFigure 3. Microstructural features in the samples in<strong>de</strong>nted at amaximum force of 100 mN (a–d) and at 10 mN (e and f). (a) SEMimage disp<strong>la</strong>ying an array of in<strong>de</strong>ntations (indicated by circles)separated by 20 lm from each other and prepared for subsequentTEM observation. The inset is a TEM bright-field image of anin<strong>de</strong>ntation which was perforated during ion milling. (b) An en<strong>la</strong>rgementcorresponding to the square drawn in the inset in (a), indicatingthe presence of nanosized crystals embed<strong>de</strong>d in an amorphous matrix.The corresponding SAED pattern confirms the presence of thecrystalline phase. (c) TEM image performed in a region located at1 lm from the edge of the hole indicated in panel (a) and en<strong>la</strong>rged inpanel (b); (d) corresponds to a region located at 10 lm from the samein<strong>de</strong>nt. (e) An en<strong>la</strong>rgement of a 10 mN in<strong>de</strong>ntation (disp<strong>la</strong>yed in thebottom right corner) revealing the presence of a high amount ofnanocrystals insi<strong>de</strong> the in<strong>de</strong>nt. (f) TEM dark-field image obtained onthe diffraction ring marked on the inset SAED pattern confirming theexistence of nanocrystallites in the amorphous matrix.an array of P max = 100 mN in<strong>de</strong>ntations separated by20 lm from each other. The inset of Figure 3a is a smallhole corresponding to one of the in<strong>de</strong>nts. Figure 3b, whichis an en<strong>la</strong>rgement of the square indicated in the inset ofFigure 3a, reveals the existence of nanocrystals with anaverage size below 7 nm near the in<strong>de</strong>nt. The correspondingSAED pattern confirms the presence of a crystallinephase. The amount of nanocrystals <strong>de</strong>creases as the distancefrom the in<strong>de</strong>nt is increased (see Fig. 3c) and nonanocrystals could be observed by TEM at 10 lm fromthe in<strong>de</strong>nt (Fig. 3d). This confirms that nanocrystallizationis in<strong>de</strong>ed induced during nanoin<strong>de</strong>ntation.The same preparation procedure was used to observenanoin<strong>de</strong>nts performed at a maximum load of 10 mN.In this case, the observed nanoin<strong>de</strong>nt (inset Fig. 3e), whichwas not perforated during the thinning process, againcontained several nanocrystals. Nanocrystallization isalso evi<strong>de</strong>nced in Figure 3f, which is a dark-field TEM imagefrom the diffraction spot highlighted in the inset, correspondingto an interp<strong>la</strong>nar distance of d = 0.204 ±