Workshop Manual

Workshop Manual

Workshop Manual

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

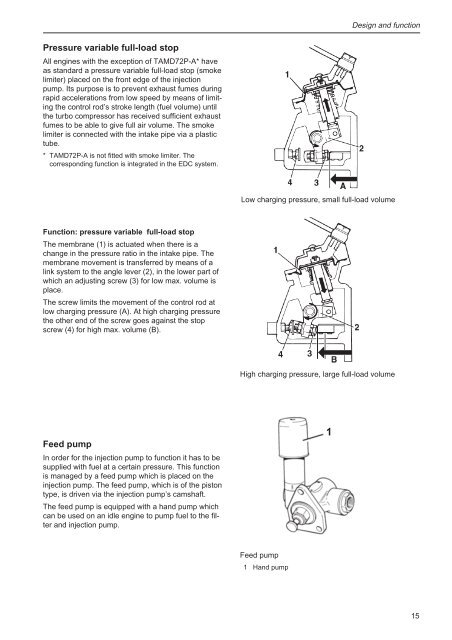

Design and functionPressure variable full-load stopAll engines with the exception of TAMD72P-A* haveas standard a pressure variable full-load stop (smokelimiter) placed on the front edge of the injectionpump. Its purpose is to prevent exhaust fumes duringrapid accelerations from low speed by means of limitingthe control rod’s stroke length (fuel volume) untilthe turbo compressor has received sufficient exhaustfumes to be able to give full air volume. The smokelimiter is connected with the intake pipe via a plastictube.* TAMD72P-A is not fitted with smoke limiter. Thecorresponding function is integrated in the EDC system.Low charging pressure, small full-load volumeFunction: pressure variable full-load stopThe membrane (1) is actuated when there is achange in the pressure ratio in the intake pipe. Themembrane movement is transferred by means of alink system to the angle lever (2), in the lower part ofwhich an adjusting screw (3) for low max. volume isplace.The screw limits the movement of the control rod atlow charging pressure (A). At high charging pressurethe other end of the screw goes against the stopscrew (4) for high max. volume (B).High charging pressure, large full-load volumeFeed pumpIn order for the injection pump to function it has to besupplied with fuel at a certain pressure. This functionis managed by a feed pump which is placed on theinjection pump. The feed pump, which is of the pistontype, is driven via the injection pump’s camshaft.The feed pump is equipped with a hand pump whichcan be used on an idle engine to pump fuel to the filterand injection pump.1Feed pump1 Hand pump15