PONSSE News 1/2011 ENG In English

PONSSE News 1/2011 ENG In English

PONSSE News 1/2011 ENG In English

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

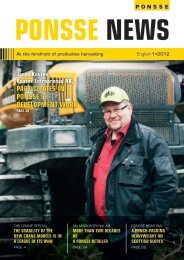

Hardware, sofTware and serviceall components of the bear are sturdier compared to the previous Ergo niklas had.charles werninger loading pine trunks with the Elephant, Ponsse’s largestforwarder, which accommodates a load of 18 tonnes.veloping one, so I should be a man of myword," he says, laughing. It is extremelynimble for such a big harvester. Many arewondering if buying such a large machinemakes sense. Although the sites are notalways dense forests, large trunks are alwaysfound. When handling them is easy,I believe that a slightly oversized machinewill give more lasting performance. Comparedto my old Ergo, everything aboutthis harvester is a bit more robust. Theframe, bogie housings and, for example,the crane extension, which has bearings atfour points instead of just two."a TOrNE VallEy BOyNiklas comes from Övertorneå in theTorne Valley. Fifteen years ago he moved1,200 kilometres south because of the forests."Here in the south the trees are sturdi-er and harvesting is more pleasant. Life iscompletely different in Norland, especiallybecause you have to travel away during theweeks. I think it's important to get homeevery night, especially if you have family."He has been working as a contractor for oversix years, since January 2005, when the Gudrunstorm hit Sweden.machiNE ruNNiNG iN TWO ShifTS"That was a good time to start, there was enoughwork to work 24-hours a day if you wanted to. Iwas driving alone at the time. Now my wife is doingthe accounting and I also have one other employee.The harvester is operated in two shifts.The objective is to have eight hours of operationin each shift. Economically, shift work is not thatprofitable, but it ensures efficient harvesting andbetter service for the sawmills," Niklas says.They are harvesting a total of 8,000–10,000cubic metres of wood every month for Ture JohanssonsTrävaru, their customer in Klevshult.<strong>PONSSE</strong> c6 TEchNical SPEcificaTiONS:Slewing torque (gross)Base tilt angleCrane turning angleLifting torque (gross)ReachLifting power with full reach"They give me work all year round. During quieterperiods, they have provided me with hardwoodharvesting. They are a good customer andalways pay me in time, for example. This is whyI want to consider their wishes and don't want toniggle over every detail."Niklas is happy to be a contractor in the forestsector, although he admits that "rainy Mondays"also exist. Jobs are performed within a radius of50 miles from Klevshult, and Niklas takes care ofmoving the machine himself using a trailer thatis registered as a tractor."These machines are too expensive for me toremove and fasten the chains and tracks for drivingon the road. These machines were not designedfor driving on public roads."55 kNm+/-20 degrees250 degrees310 kNm10 m1500 kp/10 mchristian, charles werninger andniklas savilahti say that from themachine cabin, the trunks seemsmaller than they actually are.Even the butt of the trunk,which is closest to thecamera, accounts forone cubic metre of woodand weighs a tonne.Ponsse <strong>News</strong> 1 • <strong>2011</strong> 13