PONSSE News 1/2011 ENG In English

PONSSE News 1/2011 ENG In English

PONSSE News 1/2011 ENG In English

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

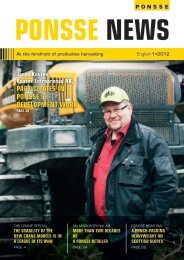

THe foresT worldwhen it comes to harvesting, the menof Karttulan metsätyö have vision andexperience.from the left: Esa Jauhiainen, hannuliikanen and ari moilanen.karTTulaN mETSäTyö Oy:GETTiNG ON TOGEThErKarttulan Metsätyö Oy, founded 20 years ago, hasestablished its position among harvesting operationscarried out in the vicinity of Kuopio. The company, whichperforms harvesting for Metsäliitto and Harvestia, alsoemploys other contractors in the region.The company is owned by Ari Moilanen,his mother Anna-Liisa Moilanen, HannuLiikanen and Esa Jauhiainen. The company'sfounder Ari Moilanen calculatesthat, in addition to seven harvesters andfour forwarders, the work employs six parttimecontractors, whose combined harvestinglast year amounted to approximately200,000 cubic metres. The fluctuation inharvesting quantities is substantial, sincethe company has accomplished twice thatin the best years.STaNdS chaNGECubic metres accumulate rapidly whenworking final-felling stands. Correspondingly,trunks are handled in large quantitiesduring thinning, while the cubic volumesremain low. The size of stands hasalso diminished noticeably during the pastfew years. Prior to the end of area taxation,the average size of a stand easily stood ataround 500 cubic metres. The average sitelast year was maybe half that size. Ari, Esaand Hannu recall that slightly before thechange in taxation policy, the largest standwas somewhere in the ballpark of 10,000cubic metres. Last year's record was a1,200 cubic-metre site.The decrease in stand-size is a sourceof concern for the men, since it inevitablyleads to more difficult harvesting. Valuableforest machines increasingly often standon platforms, on their way from one siteto the next. The reasons for this unfavourabledevelopment are many, but the breakdownof forest tracts during estate distributionsis one of them. One way to increasestand-size would be jointly-owned forests.The experience of Finnish jointly-ownedforests has been overwhelmingly positivefor all parties involved.harVESTiNGThe partners of Karttulan Metsätyö emphasisethe fact that they focus on harvestingin particular. Machines with maintenancecontracts do not pose service ormaintenance concerns for the entrepreneurs.The arrangement allows both maintenancecontractors and harvesting professionalsto concentrate on what they knowbest. Due to good cooperation, the com-pany's base at the southern edges of Kuopio isrelatively modest.The company also has experience of workingoverseas, and spent three months clearingup storm sites in Sweden in 2007. There is continueddemand on the other side of the Gulf ofBothnia, but operating in two countries has itsdifficulties. That is why the company intends tostay within a 100 km radius of Kuopio.According to the entrepreneurs, the Finnishforest sector has developed in the right direction.From twigs and stubs to the sturdiest logs,the entire forest produce has always had takers.The large-scale exploitation of the forest, carriedout in a sustainable way, is a fact that pleases theEinari Award winning entrepreneurs.The harvesting of energy wood from thinningstands has also increased strongly. The biomassand chip-run power plant set to becomeoperational in Kuopio during the current yearwill multiply the quantity of wood chips duringharvest. The harvesting of energy wood is a challengingundertaking, which needs continuousdevelopment. Ponsse's Dual has proven to bean efficient machine, as suitable for felling as itis for forwarding.aTTiTudE cOuNTSAri, Hannu and Esa have not had a shortageof operators for a while. The area's institutionstrain new operators, who tend to develop intofully blown professionals relatively quickly. Accordingto the entrepreneurs, attitude is decisivein terms of the development of a new operator.An appropriately enthusiastic operator quicklydevelops the skill set demanded by modern machines.However, the institutions should increasethe supply of practical cutting and driving opportunitiesgiven to students. Relying on traineeopenings supplied by the region's entrepreneursalone is not a sustainable solution. The instructors'practical skills could also do with somepartial honing, since the machines advance ata rapid pace. Simulator-based training is sure toprove useful, but the downside of it is not havingto explain one's mistakes to anyone. Mistakesmade in an authentic stand are visible fora long period of time and forest owners do givefeedback on them.Managing a forest machine company thesedays requires genuinely multiple skills. Managementskills have become a particularly desirableasset, because a forest machine contractorneeds to be able to calculate what is worth doingand what is not. The three-man cooperation ofKarttulan Metsätyö provides the company withthe vision, experience and synergy it needs todevelop.Ponsse <strong>News</strong> 1 • <strong>2011</strong> 35