PONSSE News 1/2011 ENG In English

PONSSE News 1/2011 ENG In English

PONSSE News 1/2011 ENG In English

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

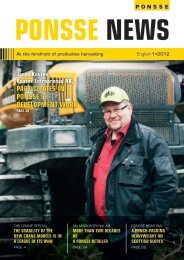

THe foresT worldaaTTo silvenToinen:SlOW aNd STEadyWiNS ThE racEIt was the end of the 1960s when Aatto Silventoinen, who grew up in the village of Särkilahti inPunkaharju, took up the forwarding of timber in the winter and the barking of pulpwood in thesummer with a Super Major and a Nuffield. That youngster probably did not even dream of someday creating and managing a full-service forest industry company employing some 20 people.Nowadays, the company founded by AattoSilventoinen has seven forest machines, fourtimber trucks and a tugboat that cleaves theshores of Saimaa in the summer. Responsibilityfor management has already beenhanded over to son-in-law Kimmo Honkanen.During the best years, the companyhas cut and forwarded some 440,000 cubicmetres of timber to the region's plants. <strong>In</strong> additionto the company's own machines, thisamount of timber has employed an equivalentnumber of other contractors in the area.cONSidErEd iNVESTmENTAatto Silventoinen purchased his first PON-SSE machine in 1985, after Valmet's Terra,Volvo's Pikku-Nalle and a Kockum."We put some serious effort into fixing upour old machine when Einari Vidgrén wason his way to make a deal on a new forestmachine. But once he got here, Einari tookonly one look at the machine standing in theyard and closed the deal," says Aatto Silventoinenwhen remembering back to his first<strong>PONSSE</strong> deal.Since then, the company has purchased25 new forest machines, but most throughcompetitive bidding, to keep up-to-date onthe market supply and cost-benefit ratios.The company's growth has been deliberate,if considered. Recent research and deliberationsinclude the most cost-effective approachesto harvesting energy wood. Sometrials have already been run with a couple ofmachines and the amount of wood chip requiredby the Kaukaa heating plant demandsfinding a successful solution quite soon.Aatto Silventoinen is no stranger to theadvances in forest machine technology. Thetransition from the plywood cabin of a farmtractor to the first machine equipped withglass windows and heating fills Aatto's memoriesas a kind of leap in user friendliness. Ofcourse, rather than taking any great leaps,the industry's development has consisted ofthe continuous repair and improvement ofdetails.With regard to actual forest machine development,Aatto considers it the result ofjoint cooperation that still continues. Theintroduction of measuring devices and informationtechnology in general was the excellentoutcome of cooperation through trialand error.BETTEr machiNES"Back in the 1970s, if someone would haveplanned to use a forest machine for a good15,000 hours without a basic overhaul, itwould have raised some eyebrows. But thesedays, a well serviced machine operated by aprofessional easily works through the 15,000hours without problems," says Aatto on thedevelopment of machines.<strong>In</strong> Silventoinen's company, the lowerthreshold for replacing machines is the15,000 hours of use mentioned, after whichthe idea of a new machine is taken underconsideration. Once upgraded, the used machineshave almost without exception founda new user among full-blooded contractors.Aatto Silventoinen stresses the importancethat good service holds for successfulmachine contracting. Modern machines demandincreasing attention and cleanlinessis a particularly important issue, since theincreased amount of electronics and electricvalves do not tolerate neglect nor impurities."When there is a skilled operator in thecabin of a well serviced machine, the likelihoodof carefree work increases significantly,"remarks Aatto.The company services it machines largelyindependently, but there is an authorised<strong>PONSSE</strong> service in nearby Punkasalmi. AattoSilventoinen finds it difficult to go intospecifics when explaining his choice of machinerybecause, when choosing forest machines,it is precisely the whole which is ofdecisive importance. Everything from salesto service and a new machine deal has to gosmoothly.iNTErESTiNG WOrkThe longest-standing operators of forestmachines among Silventoinen's staff haveworked for the company for more than 40years. Employee turnover is very low, a factthat makes Aatto Silventoinen happy. Workwith skillful professionals flows smoothlyand many issues are resolved before theystart causing problems.Educational establishments are also activein offering trainees for Silventoinen'scompany. However, teaching a student howto use a demanding machine ties up the company'professionals to a great degree. If forestmachine operators fresh out of college wouldcommit to working in the company, it wouldsurely facilitate the obtaining of trainee positions.That is why a more comprehensiveagreement on the gain of operations betweenschools and companies would be in order.Silventoinen's company has also trainedoperators itself from the start. These operatorsprovided with training and a vocationhave agreed to work for the company in exchangefor training. According to Aatto Silventoinen,such mutually beneficial arrangementsconstitute a sustainable way of preparingfor the future.faVOuraBlE TrENdSAatto considers the current timber tradegood in comparison to the operations ofyears gone by. As late as during the 1980s,one could be delivering stocks up to twoyears old to plants. This system created agreat degree of fluctuation in both harvestingand supply, which was difficult for bothcontractors and forest owners.36Ponsse <strong>News</strong> 1 • <strong>2011</strong>