EMI/EMP Filter Connectors Catalog - Glenair, Inc.

EMI/EMP Filter Connectors Catalog - Glenair, Inc.

EMI/EMP Filter Connectors Catalog - Glenair, Inc.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

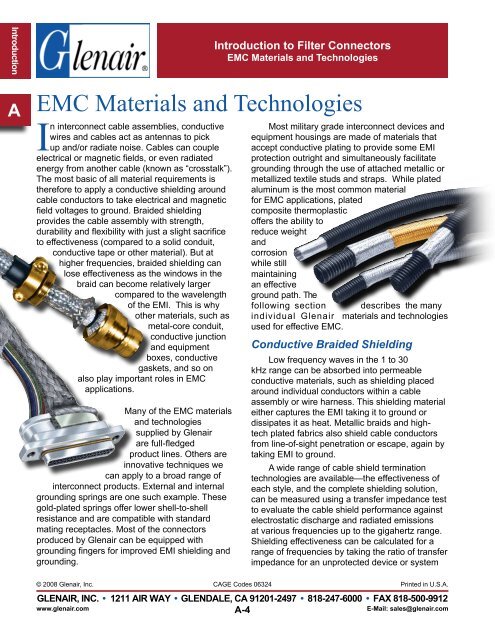

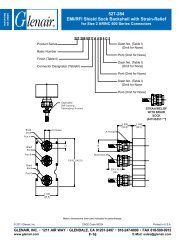

IntroductionIntroduction to <strong>Filter</strong> <strong>Connectors</strong>EMC Materials and TechnologiesAEMC Materials and TechnologiesIn interconnect cable assemblies, conductivewires and cables act as antennas to pickup and/or radiate noise. Cables can coupleelectrical or magnetic fields, or even radiatedenergy from another cable (known as “crosstalk”).The most basic of all material requirements istherefore to apply a conductive shielding aroundcable conductors to take electrical and magneticfield voltages to ground. Braided shieldingprovides the cable assembly with strength,durability and flexibility with just a slight sacrificeto effectiveness (compared to a solid conduit,conductive tape or other material). But athigher frequencies, braided shielding canlose effectiveness as the windows in thebraid can become relatively largercompared to the wavelengthof the <strong>EMI</strong>. This is whyother materials, such asmetal-core conduit,conductive junctionand equipmentboxes, conductivegaskets, and so onalso play important roles in EMCapplications.Many of the EMC materialsand technologiessupplied by <strong>Glenair</strong>are full-fledgedproduct lines. Others areinnovative techniques wecan apply to a broad range ofinterconnect products. External and internalgrounding springs are one such example. Thesegold-plated springs offer lower shell-to-shellresistance and are compatible with standardmating receptacles. Most of the connectorsproduced by <strong>Glenair</strong> can be equipped withgrounding fingers for improved <strong>EMI</strong> shielding andgrounding.Most military grade interconnect devices andequipment housings are made of materials thataccept conductive plating to provide some <strong>EMI</strong>protection outright and simultaneously facilitategrounding through the use of attached metallic ormetallized textile studs and straps. While platedaluminum is the most common materialfor EMC applications, platedcomposite thermoplasticoffers the ability toreduce weightandcorrosionwhile stillmaintainingan effectiveground path. Thefollowing section describes the manyindividual <strong>Glenair</strong> materials and technologiesused for effective EMC.Conductive Braided ShieldingLow frequency waves in the 1 to 30kHz range can be absorbed into permeableconductive materials, such as shielding placedaround individual conductors within a cableassembly or wire harness. This shielding materialeither captures the <strong>EMI</strong> taking it to ground ordissipates it as heat. Metallic braids and hightechplated fabrics also shield cable conductorsfrom line-of-sight penetration or escape, again bytaking <strong>EMI</strong> to ground.A wide range of cable shield terminationtechnologies are available—the effectiveness ofeach style, and the complete shielding solution,can be measured using a transfer impedance testto evaluate the cable shield performance againstelectrostatic discharge and radiated emissionsat various frequencies up to the gigahertz range.Shielding effectiveness can be calculated for arange of frequencies by taking the ratio of transferimpedance for an unprotected device or system© 2008 <strong>Glenair</strong>, <strong>Inc</strong>. CAGE Codes 06324Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.comA-4E-Mail: sales@glenair.com