Single-Chip Low Cost Low Power RF-Transceiver (Rev. B

Single-Chip Low Cost Low Power RF-Transceiver (Rev. B

Single-Chip Low Cost Low Power RF-Transceiver (Rev. B

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

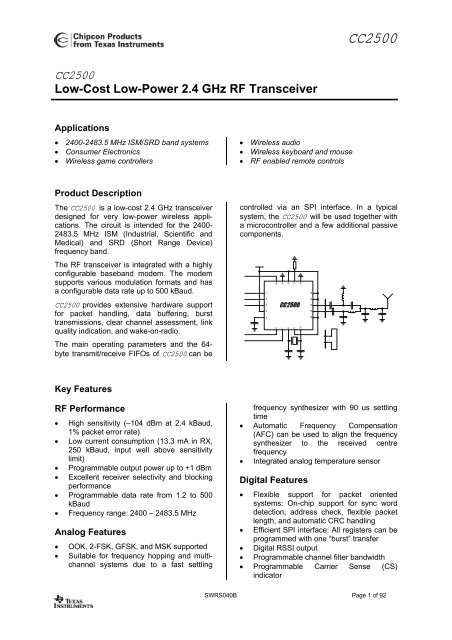

6789CC2500CC2500<strong>Low</strong>-<strong>Cost</strong> <strong>Low</strong>-<strong>Power</strong> 2.4 GHz <strong>RF</strong> <strong>Transceiver</strong>Applications• 2400-2483.5 MHz ISM/SRD band systems• Consumer Electronics• Wireless game controllers• Wireless audio• Wireless keyboard and mouse• <strong>RF</strong> enabled remote controlsProduct DescriptionThe CC2500 is a low-cost 2.4 GHz transceiverdesigned for very low-power wireless applications.The circuit is intended for the 2400-2483.5 MHz ISM (Industrial, Scientific andMedical) and SRD (Short Range Device)frequency band.The <strong>RF</strong> transceiver is integrated with a highlyconfigurable baseband modem. The modemsupports various modulation formats and hasa configurable data rate up to 500 kBaud.CC2500 provides extensive hardware supportfor packet handling, data buffering, bursttransmissions, clear channel assessment, linkquality indication, and wake-on-radio.The main operating parameters and the 64-byte transmit/receive FIFOs of CC2500 can becontrolled via an SPI interface. In a typicalsystem, the CC2500 will be used together witha microcontroller and a few additional passivecomponents.201918171610Key Features<strong>RF</strong> Performance• High sensitivity (–104 dBm at 2.4 kBaud,1% packet error rate)• <strong>Low</strong> current consumption (13.3 mA in RX,250 kBaud, input well above sensitivitylimit)• Programmable output power up to +1 dBm• Excellent receiver selectivity and blockingperformance• Programmable data rate from 1.2 to 500kBaud• Frequency range: 2400 – 2483.5 MHzAnalog Features• OOK, 2-FSK, GFSK, and MSK supported• Suitable for frequency hopping and multichannelsystems due to a fast settlingfrequency synthesizer with 90 us settlingtime• Automatic Frequency Compensation(AFC) can be used to align the frequencysynthesizer to the received centrefrequency• Integrated analog temperature sensorDigital Features• Flexible support for packet orientedsystems: On-chip support for sync worddetection, address check, flexible packetlength, and automatic CRC handling• Efficient SPI interface: All registers can beprogrammed with one “burst” transfer• Digital RSSI output• Programmable channel filter bandwidth• Programmable Carrier Sense (CS)indicatorSWRS040B Page 1 of 92

CC2500• Programmable Preamble Quality Indicator(PQI) for improved protection against falsesync word detection in random noise• Support for automatic Clear ChannelAssessment (CCA) before transmitting (forlisten-before-talk systems)• Support for per-package Link QualityIndication (LQI)• Optional automatic whitening and dewhiteningof data<strong>Low</strong>-<strong>Power</strong> Features• 400 nA SLEEP mode current consumption• Fast startup time: 240 us from SLEEP toRX or TX mode (measured on EM design)• Wake-on-radio functionality for automaticlow-power RX polling• Separate 64-byte RX and TX data FIFOs(enables burst mode data transmission)General• Few external components: Complete onchipfrequency synthesizer, no externalfilters or <strong>RF</strong> switch needed• Green package: RoHS compliant and noantimony or bromine• Small size (QLP 4x4 mm package, 20pins)• Suited for systems compliant with EN 300328 and EN 300 440 class 2 (Europe),FCC CFR47 Part 15 (US), and ARIB STD-T66 (Japan)• Support for asynchronous andsynchronous serial receive/transmit modefor backwards compatibility with existingradio communication protocolsSWRS040B Page 2 of 92

CC2500AbbreviationsAbbreviations used in this data sheet are described below.ACP Adjacent Channel <strong>Power</strong> MSB Most Significant BitADC Analog to Digital Converter MSK Minimum Shift KeyingAFC Automatic Frequency Offset Compensation NA Not ApplicableAGC Automatic Gain Control NRZ Non Return to Zero (Coding)AMR Automatic Meter Reading OOK On Off KeyingARIB Association of Radio Industries and Businesses PA <strong>Power</strong> AmplifierBER Bit Error Rate PCB Printed Circuit BoardBT Bandwidth-Time product PD <strong>Power</strong> DownCCA Clear Channel Assessment PER Packet Error RateCFR Code of Federal Regulations PLL Phase Locked LoopCRC Cyclic Redundancy Check POR <strong>Power</strong>-on ResetCS Carrier Sense PQI Preamble Quality IndicatorCW Continuous Wave (Unmodulated Carrier) PQT Preamble Quality ThresholdDC Direct Current RCOSC RC OscillatorDVGA Digital Variable Gain Amplifier QPSK Quadrature Phase Shift KeyingESR Equivalent Series Resistance QLP Quad Leadless PackageFCC Federal Communications Commission RC Resistor-CapacitorFEC Forward Error Correction <strong>RF</strong> Radio FrequencyFIFO First-In-First-Out RSSI Received Signal Strength IndicatorFHSS Frequency Hopping Spread Spectrum RX Receive, Receive Mode2-FSK Frequency Shift Keying SAW Surface Aqustic WaveGFSK Gaussian shaped Frequency Shift Keying SMD Surface Mount DeviceIF Intermediate Frequency SNR Signal to Noise RatioI/Q In-Phase/Quadrature SPI Serial Peripheral InterfaceISM Industrial, Scientific and Medical SRD Short Range DeviceLBT Listen Before Transmit T/R Transmit/ReceiveLC Inductor-Capacitor TX Transmit, Transmit ModeLNA <strong>Low</strong> Noise Amplifier VCO Voltage Controlled OscillatorLO Local Oscillator WLAN Wireless Local Area NetworksLQI Link Quality Indicator WOR Wake on Radio, <strong>Low</strong> power pollingLSB Least Significant Bit XOSC Crystal OscillatorMCU Microcontroller Unit XTAL CrystalSWRS040B Page 3 of 92

CC2500Table of ContentsAPPLICATIONS...........................................................................................................................................1PRODUCT DESCRIPTION.........................................................................................................................1KEY FEATURES ..........................................................................................................................................1<strong>RF</strong> PE<strong>RF</strong>ORMANCE ...........................................................................................................................................1ANALOG FEATURES..........................................................................................................................................1DIGITAL FEATURES ..........................................................................................................................................1LOW-POWER FEATURES ...................................................................................................................................2GENERAL..........................................................................................................................................................2ABBREVIATIONS........................................................................................................................................3TABLE OF CONTENTS ..............................................................................................................................41 ABSOLUTE MAXIMUM RATINGS...........................................................................................................72 OPERATING CONDITIONS......................................................................................................................73 GENERAL CHARACTERISTICS ...............................................................................................................74 ELECTRICAL SPECIFICATIONS...............................................................................................................84.1 CURRENT CONSUMPTION .....................................................................................................................84.2 <strong>RF</strong> RECEIVE SECTION.........................................................................................................................104.3 <strong>RF</strong> TRANSMIT SECTION ......................................................................................................................124.4 CRYSTAL OSCILLATOR.......................................................................................................................134.5 LOW POWER RC OSCILLATOR............................................................................................................134.6 FREQUENCY SYNTHESIZER CHARACTERISTICS...................................................................................144.7 ANALOG TEMPERATURE SENSOR .......................................................................................................154.8 DC CHARACTERISTICS .......................................................................................................................154.9 POWER-ON RESET..............................................................................................................................155 PIN CONFIGURATION ..........................................................................................................................166 CIRCUIT DESCRIPTION........................................................................................................................187 APPLICATION CIRCUIT........................................................................................................................188 CONFIGURATION OVERVIEW ..............................................................................................................209 CONFIGURATION SOFTWARE ..............................................................................................................2110 4-WIRE SERIAL CONFIGURATION AND DATA INTE<strong>RF</strong>ACE ...................................................................2210.1 CHIP STATUS BYTE ............................................................................................................................2310.2 REGISTER ACCESS..............................................................................................................................2410.3 SPI READ ...........................................................................................................................................2410.4 COMMAND STROBES ..........................................................................................................................2510.5 FIFO ACCESS .....................................................................................................................................2510.6 PATABLE ACCESS .............................................................................................................................2511 MICROCONTROLLER INTE<strong>RF</strong>ACE AND PIN CONFIGURATION...............................................................2611.1 CONFIGURATION INTE<strong>RF</strong>ACE..............................................................................................................2611.2 GENERAL CONTROL AND STATUS PINS ..............................................................................................2611.3 OPTIONAL RADIO CONTROL FEATURE ...............................................................................................2712 DATA RATE PROGRAMMING...............................................................................................................2713 RECEIVER CHANNEL FILTER BANDWIDTH..........................................................................................2814 DEMODULATOR, SYMBOL SYNCHRONIZER AND DATA DECISION.......................................................2814.1 FREQUENCY OFFSET COMPENSATION.................................................................................................2814.2 BIT SYNCHRONIZATION......................................................................................................................2814.3 BYTE SYNCHRONIZATION...................................................................................................................2915 PACKET HANDLING HARDWARE SUPPORT .........................................................................................2915.1 DATA WHITENING..............................................................................................................................3015.2 PACKET FORMAT................................................................................................................................3015.3 PACKET FILTERING IN RECEIVE MODE...............................................................................................3215.4 CRC CHECK .......................................................................................................................................3215.5 PACKET HANDLING IN TRANSMIT MODE............................................................................................3315.6 PACKET HANDLING IN RECEIVE MODE ..............................................................................................3315.7 PACKET HANDLING IN FIRMWARE......................................................................................................3416 MODULATION FORMATS.....................................................................................................................3416.1 FREQUENCY SHIFT KEYING................................................................................................................3416.2 MINIMUM SHIFT KEYING....................................................................................................................34SWRS040B Page 4 of 92

CC250016.3 AMPLITUDE MODULATION .................................................................................................................3517 RECEIVED SIGNAL QUALIFIERS AND LINK QUALITY INFORMATION...................................................3517.1 SYNC WORD QUALIFIER.....................................................................................................................3517.2 PREAMBLE QUALITY THRESHOLD (PQT) ...........................................................................................3517.3 RSSI...................................................................................................................................................3517.4 CARRIER SENSE (CS)..........................................................................................................................3617.5 CLEAR CHANNEL ASSESSMENT (CCA) ..............................................................................................3817.6 LINK QUALITY INDICATOR (LQI).......................................................................................................3818 FORWARD ERROR CORRECTION WITH INTERLEAVING........................................................................3818.1 FORWARD ERROR CORRECTION (FEC)...............................................................................................3818.2 INTERLEAVING ...................................................................................................................................3919 RADIO CONTROL ................................................................................................................................4019.1 POWER-ON START-UP SEQUENCE......................................................................................................4019.2 CRYSTAL CONTROL............................................................................................................................4119.3 VOLTAGE REGULATOR CONTROL.......................................................................................................4119.4 ACTIVE MODES ..................................................................................................................................4219.5 WAKE ON RADIO (WOR)...................................................................................................................4219.6 TIMING ...............................................................................................................................................4319.7 RX TERMINATION TIMER ...................................................................................................................4420 DATA FIFO ........................................................................................................................................4421 FREQUENCY PROGRAMMING ..............................................................................................................4522 VCO...................................................................................................................................................4622.1 VCO AND PLL SELF-CALIBRATION ...................................................................................................4623 VOLTAGE REGULATORS .....................................................................................................................4724 OUTPUT POWER PROGRAMMING ........................................................................................................4725 SELECTIVITY ......................................................................................................................................4926 CRYSTAL OSCILLATOR.......................................................................................................................5126.1 REFERENCE SIGNAL ...........................................................................................................................5127 EXTERNAL <strong>RF</strong> MATCH .......................................................................................................................5128 PCB LAYOUT RECOMMENDATIONS....................................................................................................5229 GENERAL PURPOSE / TEST OUTPUT CONTROL PINS ...........................................................................5330 ASYNCHRONOUS AND SYNCHRONOUS SERIAL OPERATION................................................................5530.1 ASYNCHRONOUS OPERATION..............................................................................................................5530.2 SYNCHRONOUS SERIAL OPERATION ....................................................................................................5531 SYSTEM CONSIDERATIONS AND GUIDELINES......................................................................................5531.1 SRD REGULATIONS............................................................................................................................5531.2 FREQUENCY HOPPING AND MULTI-CHANNEL SYSTEMS.....................................................................5631.3 WIDEBAND MODULATION NOT USING SPREAD SPECTRUM ................................................................5631.4 DATA BURST TRANSMISSIONS............................................................................................................5631.5 CONTINUOUS TRANSMISSIONS ...........................................................................................................5631.6 CRYSTAL DRIFT COMPENSATION .......................................................................................................5731.7 SPECTRUM EFFICIENT MODULATION..................................................................................................5731.8 LOW COST SYSTEMS ..........................................................................................................................5731.9 BATTERY OPERATED SYSTEMS ..........................................................................................................5731.10 INCREASING OUTPUT POWER .........................................................................................................5732 CONFIGURATION REGISTERS ..............................................................................................................5832.1 CONFIGURATION REGISTER DETAILS – REGISTERS WITH PRESERVED VALUES IN SLEEP STATE ......6232.2 CONFIGURATION REGISTER DETAILS – REGISTERS THAT LOSE PROGRAMMING IN SLEEP STATE.....8132.3 STATUS REGISTER DETAILS................................................................................................................8233 PACKAGE DESCRIPTION (QLP 20)......................................................................................................8633.1 RECOMMENDED PCB LAYOUT FOR PACKAGE (QLP 20) ....................................................................8733.2 SOLDERING INFORMATION .................................................................................................................8733.3 TRAY SPECIFICATION .........................................................................................................................8733.4 CARRIER TAPE AND REEL SPECIFICATION..........................................................................................8834 ORDERING INFORMATION...................................................................................................................8835 REFERENCES.......................................................................................................................................8836 GENERAL INFORMATION ....................................................................................................................8936.1 DOCUMENT HISTORY .........................................................................................................................8936.2 PRODUCT STATUS DEFINITIONS .........................................................................................................90SWRS040B Page 5 of 92

CC250037 ADDRESS INFORMATION.....................................................................................................................9138 TI WORLDWIDE TECHNICAL SUPPORT ...............................................................................................91SWRS040B Page 6 of 92

CC25001 Absolute Maximum RatingsUnder no circumstances must the absolute maximum ratings given in Table 1 be violated. Stressexceeding one or more of the limiting values may cause permanent damage to the device.Caution! ESD sensitive device.Precaution should be used when handlingthe device in order to prevent permanentdamage.Parameter Min Max Unit ConditionSupply voltage –0.3 3.9 V All supply pins must have the same voltageVoltage on any digital pin –0.3 VDD+0.3,max 3.9VVoltage on the pins <strong>RF</strong>_P, <strong>RF</strong>_Nand DCOUPL–0.3 2.0 VVoltage ramp-up rate 120 kV/µsInput <strong>RF</strong> level +10 dBmStorage temperature range –50 150 °CSolder reflow temperature 260 °C According to IPC/JEDEC J-STD-020CESD

CC25004 Electrical Specifications4.1 Current ConsumptionTc = 25°C, VDD = 3.0 V if nothing else stated. All measurement results obtained using the CC2500EM reference design([4]).Parameter Min Typ Max Unit ConditionCurrent consumption inpower down modes400 nA Voltage regulator to digital part off, register values retained(SLEEP state). All GDO pins programmed to 0x2F (HW to 0)900 nA Voltage regulator to digital part off, register values retained, lowpowerRC oscillator running (SLEEP state with WOR enabled)92 µA Voltage regulator to digital part off, register values retained,XOSC running (SLEEP state with MCSM0.OSC_FORCE_ON set)160 µA Voltage regulator to digital part on, all other modules in powerdown (XOFF state)Current consumption8.1 µA Automatic RX polling once each second, using low-power RCoscillator, with 460 kHz filter bandwidth and 250 kBaud data rate,PLL calibration every 4 th wakeup. Average current with signal inchannel below carrier sense level (MCSM2.RX_TIME_RSSI=1).35 µA Same as above, but with signal in channel above carrier senselevel, 1.95 ms RX timeout, and no preamble/sync word found.1.4 µA Automatic RX polling every 15 th second, using low-power RCoscillator, with 460 kHz filter bandwidth and 250 kBaud data rate,PLL calibration every 4 th wakeup. Average current with signal inchannel below carrier sense level (MCSM2.RX_TIME_RSSI=1).34 µA Same as above, but with signal in channel above carrier senselevel, 29.3 ms RX timeout, and no preamble/sync word found.1.5 mA Only voltage regulator to digital part and crystal oscillator running(IDLE state)7.4 mA Only the frequency synthesizer is running (FSTXON state). Thiscurrents consumption is also representative for the otherintermediate states when going from IDLE to RX or TX, includingthe calibration state.Current consumption,RX states17.0 mA Receive mode, 2.4 kBaud, input at sensitivity limit,MDMCFG2.DEM_DCFILT_OFF=014.5 mA Receive mode, 2.4 kBaud, input well above sensitivity limit,MDMCFG2.DEM_DCFILT_OFF=017.3 mA Receive mode, 10 kBaud, input at sensitivity limit,MDMCFG2.DEM_DCFILT_OFF=014.9 mA Receive mode, 10 kBaud, input well above sensitivity limit,MDMCFG2.DEM_DCFILT_OFF=018.8 mA Receive mode, 250 kBaud, input at sensitivity limit,MDMCFG2.DEM_DCFILT_OFF=015.7 mA Receive mode, 250 kBaud, input well above sensitivity limit,MDMCFG2.DEM_DCFILT_OFF=016.6 mA Receive mode, 250 kBaud current optimized, input at sensitivitylimit, MDMCFG2.DEM_DCFILT_OFF=113.3 mA Receive mode, 250 kBaud current optimized, input well abovesensitivity limit, MDMCFG2.DEM_DCFILT_OFF=119.6 mA Receive mode, 500 kBaud, input at sensitivity limit,MDMCFG2.DEM_DCFILT_OFF=017.0 mA Receive mode, 500 kBaud, input well above sensitivity limit,MDMCFG2.DEM_DCFILT_OFF=0SWRS040B Page 8 of 92

CC2500Current consumption,TX states11.1 mA Transmit mode, –12 dBm output power15.0 mA Transmit mode, -6 dBm output power21.2 mA Transmit mode, 0 dBm output power21.5 mA Transmit mode, +1 dBm output powerTable 4: Current ConsumptionSWRS040B Page 9 of 92

CC25004.2 <strong>RF</strong> Receive SectionTc = 25°C, VDD = 3.0 V if nothing else stated. All measurement results obtained using the CC2500EM reference design([4]).Parameter Min Typ Max Unit Condition/NoteDigital channel filterbandwidth58 812 kHz User programmable. The bandwidth limits areproportional to crystal frequency (given values assumea 26.0 MHz crystal).2.4 kBaud data rate, sensitivity optimized, MDMCFG2.DEM_DCFILT_OFF=0(2-FSK, 1% packet error rate, 20 bytes packet length, 203 kHz digital channel filter bandwidth)Receiver sensitivity –104 dBm The RX current consumption can be reduced byapproximately 1.7 mA by settingMDMCFG2.DEM_DCFILT_OFF=1. The typical sensitivityis then -102 dBm and the temperature range is from 0 o Cto +85 o C.Saturation –13 dBmAdjacent channelrejectionAlternate channelrejectionBlocking±10 MHz offset±20 MHz offset±50 MHz offsetThe sensitivity can be improved to typically –106 dBmwith MDMCFG2.DEM_DCFILT_OFF=0 by programmingregisters TEST2 and TEST1 (see page 82). Thetemperature range is then from 0 o C to +85 o C.23 dB Desired channel 3 dB above the sensitivity limit. 250kHz channel spacing31 dB Desired channel 3 dB above the sensitivity limit. 250kHz channel spacingSee Figure 22 for plot of selectivity versus frequencyoffset647071dBmdBmdBmWanted signal 3 dB above sensitivity level.Compliant with ETSI EN 300 440 class 2 receiverrequirements.10 kBaud data rate, sensitivity optimized, MDMCFG2.DEM_DCFILT_OFF=0(2-FSK, 1% packet error rate, 20 bytes packet length, 232 kHz digital channel filter bandwidth)Receiver sensitivity –99 dBm The RX current consumption can be reduced byapproximately 1.7 mA by settingMDMCFG2.DEM_DCFILT_OFF=1. The typical sensitivityis then -97 dBmSaturation –9 dBmAdjacent channelrejectionAlternate channelrejectionBlocking±10 MHz offset±20 MHz offset±50 MHz offsetThe sensitivity can be improved to typically –101 dBmwith MDMCFG2.DEM_DCFILT_OFF=0 by programmingregisters TEST2 and TEST1 (see page 82). Thetemperature range is then from 0 o C to +85 o C.18 dB Desired channel 3 dB above the sensitivity limit. 250kHz channel spacing25 dB Desired channel 3 dB above the sensitivity limit. 250kHz channel spacingSee Figure 23 for plot of selectivity versus frequencyoffset596566dBdBdBWanted signal 3 dB above sensitivity level.Compliant with ETSI EN 300 440 class 2 receiverrequirements.SWRS040B Page 10 of 92

CC2500Parameter Min Typ Max Unit Condition/Note250 kBaud data rate, sensitivity optimized, MDMCFG2.DEM_DCFILT_OFF=0(MSK, 1% packet error rate, 20 bytes packet length, 540 kHz digital channel filter bandwidth)Receiver sensitivity –89 dBmSaturation –13 dBmAdjacent channel rejection 21 dB Desired channel 3 dB above the sensitivity limit. 750kHz channel spacingAlternate channel rejection 30 dB Desired channel 3 dB above the sensitivity limit. 750kHz channel spacingBlocking±10 MHz offset±20 MHz offset±50 MHz offset465355dBdBdBSee Figure 24 for plot of selectivity versus frequencyoffsetWanted signal 3 dB above sensitivity level.Compliant with ETSI EN 300 440 class 2 receiverrequirements.250 kBaud data rate, current optimized, MDMCFG2.DEM_DCFILT_OFF=1(MSK, 1% packet error rate, 20 bytes packet length, 540 kHz digital channel filter bandwidth)Receiver sensitivity –87 dBmSaturation –12 dBmAdjacent channel rejection 21 dB Desired channel 3 dB above the sensitivity limit. 750kHz channel spacingAlternate channel rejection 30 dB Desired channel 3 dB above the sensitivity limit. 750kHz channel spacingSee Figure 25 for plot of selectivity versus frequencyoffsetBlocking±10 MHz offset±20 MHz offset4652dBdBWanted signal 3 dB above sensitivity level.Compliant with ETSI EN 300 440 class 2 receiverrequirements.±50 MHz offset55dB500 kBaud data rate, MDMCFG2.DEM_DCFILT_OFF=0 (MDMCFG2.DEM_DCFILT_OFF=1 cannot be used for data rates>250 kBaud)(MSK, 1% packet error rate, 20 bytes packet length, 812 kHz digital channel filter bandwidth)Receiver sensitivity –83 dBmSaturation –18 dBmAdjacent channel rejection 14 dB Desired channel 3 dB above the sensitivity limit. 1 MHzchannel spacingAlternate channel rejection 25 dB Desired channel 3 dB above the sensitivity limit. 1 MHzchannel spacingSee Figure 26 for plot of selectivity versus frequencyoffsetBlocking±10 MHz offset±20 MHz offset4048dBdBWanted signal 3 dB above sensitivity level.Compliant with ETSI EN 300 440 class 2 receiverrequirements.±50 MHz offset50dBGeneralSpurious emissions25 MHz – 1 GHzAbove 1 GHz–57–47dBmdBmRX latency 9 bit Serial operation. Time from start of reception until datais available on the receiver data output pin is equal to 9bit.Table 5: <strong>RF</strong> Receive SectionSWRS040B Page 11 of 92

CC25004.3 <strong>RF</strong> Transmit SectionTc = 25°C, VDD = 3.0 V, 0 dBm if nothing else stated. All measurement results obtained using the CC2500EM referencedesign ([4]).Parameter Min Typ Max Unit Condition/NoteDifferential loadimpedanceOutput power,highest settingOutput power,lowest settingOccupied bandwidth(99%)Adjacent channelpower (ACP)Spurious emissions25 MHz – 1 GHz47-74, 87.5-118, 174-230, 470-862 MHz1800-1900 MHzAt 2·<strong>RF</strong> and 3·<strong>RF</strong>Otherwise above 1GHz80 + j74 Ω Differential impedance as seen from the <strong>RF</strong>-port (<strong>RF</strong>_P and<strong>RF</strong>_N) towards the antenna. Follow the CC2500EMreference design ([4]) available from the TI website.+1 dBm Output power is programmable and full range is availableacross the entire frequency band.Delivered to a 50 Ω single-ended load via CC2500EMreference design ([4]) <strong>RF</strong> matching network.–30 dBm Output power is programmable and full range is availableacross the entire frequency band.91117296489-28-27-22-21–36–54–47–41–30kHzkHzkHzkHzdBcdBcdBcdBcdBmdBmdBmdBmdBmDelivered to a 50 Ω single-ended load via CC2500EMreference design ([4]) <strong>RF</strong> matching network.It is possible to program less than -30 dBm output power,but this is not recommended due to large variation in outputpower across operating conditions and processing cornersfor these settings.2.4 kBaud, 38.2 kHz deviation, 2-FSK10 kBaud, 38.2 kHz deviation, 2-FSK250 kBaud, MSK500 kBaud, MSK2.4 kBaud, 38.2 kHz deviation, 2-FSK, 250 kHz channelspacing10 kBaud, 38.2 kHz deviation, 2-FSK, 250 kHz channelspacing250 kBaud, MSK, 750 kHz channel spacing500 kBaud, MSK, 1 MHz channel spacingRestricted band in EuropeRestricted bands in USATX latency 8 bit Serial operation. Time from sampling the data on thetransmitter data input pin until it is observed on the <strong>RF</strong>output ports.Table 6: <strong>RF</strong> Transmit SectionSWRS040B Page 12 of 92

CC25004.4 Crystal OscillatorTc = 25°C, VDD = 3.0 V if nothing else stated.Parameter Min Typ Max Unit Condition/NoteCrystal frequency 26 26 27 MHzTolerance ±40 ppm This is the total tolerance including a) initial tolerance, b) crystalloading, c) aging, and d) temperature dependence.The acceptable crystal tolerance depends on <strong>RF</strong> frequency andchannel spacing / bandwidth.ESR 100 ΩStart-up time 150 µs Measured on CC2500EM reference design ([4]) using crystalAT-41CD2 from NDK.This parameter is to a large degree crystal dependent.Table 7: Crystal Oscillator Parameters4.5 <strong>Low</strong> <strong>Power</strong> RC OscillatorTc = 25°C, VDD = 3.0 V if nothing else stated. All measurement results obtained using the CC2500EM reference design([4]).Parameter Min Typ Max Unit Condition/NoteCalibrated frequency 34.7 34.7 36 kHz Calibrated RC oscillator frequency is XTALfrequency divided by 750Frequency accuracy aftercalibration-1 /+10% The RC oscillator contains an error in thecalibration routine that statistically occurs in17.3% of all calibrations performed. The givenmaximum accuracy figures account for thecalibration error. Refer also to the CC2500Errata Notes.Temperature coefficient +0.4 % / °C Frequency drift when temperature changesafter calibrationSupply voltage coefficient +3 % / V Frequency drift when supply voltage changesafter calibrationInitial calibration time 2 ms When the RC oscillator is enabled, calibrationis continuously done in the background as longas the crystal oscillator is running.Table 8: RC Oscillator ParametersSWRS040B Page 13 of 92

CC25004.6 Frequency Synthesizer CharacteristicsTc = 25°C, VDD = 3.0 V if nothing else stated. All measurement results obtained using the CC2500EM reference design([4]). Min figures are given using a 27 MHz crystal. Typ and max figures are given using a 26 MHz crystal.Parameter Min Typ Max Unit Condition/NoteProgrammedfrequency resolutionSynthesizer frequencytolerance<strong>RF</strong> carrier phase noise397 F XOSC /2 16 412 Hz 26-27 MHz crystal.±40 ppm Given by crystal used. Required accuracy (includingtemperature and aging) depends on frequency band andchannel bandwidth / spacing.–78 dBc/Hz @ 50 kHz offset from carrier–78 dBc/Hz @ 100 kHz offset from carrier–81 dBc/Hz @ 200 kHz offset from carrier–90 dBc/Hz @ 500 kHz offset from carrier–100 dBc/Hz @ 1 MHz offset from carrier–108 dBc/Hz @ 2 MHz offset from carrier–114 dBc/Hz @ 5 MHz offset from carrier–118 dBc/Hz @ 10 MHz offset from carrierPLL turn-on / hop time 85.1 88.4 88.4 µs Time from leaving the IDLE state until arriving in the RX,FSTXON or TX state, when not performing calibration.Crystal oscillator running.PLL RX/TX settlingtimePLL TX/RX settlingtime9.3 9.6 9.6 µs Settling time for the 1·IF frequency step from RX to TX20.7 21.5 21.5 µs Settling time for the 1·IF frequency step from TX to RXPLL calibration time 694 721 721 µs Calibration can be initiated manually or automaticallybefore entering or after leaving RX/TX.Table 9: Frequency Synthesizer ParametersSWRS040B Page 14 of 92

CC25004.7 Analog Temperature SensorThe characteristics of the analog temperature sensor at 3.0 V supply voltage are listed in Table10 below. Note that it is necessary to write 0xBF to the PTEST register to use the analogtemperature sensor in the IDLE state.Parameter Min Typ Max Unit Condition/NoteOutput voltage at –40°C 0.654 VOutput voltage at 0°C 0.750 VOutput voltage at +40°C 0.848 VOutput voltage at +80°C 0.946 VTemperature coefficient 2.43 mV/°C Fitted from –20°C to +80°CError in calculatedtemperature, calibratedCurrent consumptionincrease when enabled-2 * 0 2 * °C From –20°C to +80°C when using 2.43 mV / °C,after 1-point calibration at room temperature0.3 mA* The indicated minimum and maximum error with 1-point calibration is based on measured values fortypical process parametersTable 10: Analog Temperature Sensor Parameters4.8 DC CharacteristicsTc = 25°C if nothing else stated.Digital Inputs/Outputs Min Max Unit ConditionLogic "0" input voltage 0 0.7 VLogic "1" input voltage VDD-0.7 VDD VLogic "0" output voltage 0 0.5 V For up to 4 mA output currentLogic "1" output voltage VDD-0.3 VDD V For up to 4 mA output currentLogic "0" input current N/A –50 nA Input equals 0 VLogic "1" input current N/A 50 nA Input equals VDDTable 11: DC Characteristics4.9 <strong>Power</strong>-On ResetWhen the power supply complies with the requirements in Table 12 below, proper <strong>Power</strong>-On-Reset functionality is guaranteed. Otherwise, the chip should be assumed to have unknown stateuntil transmitting an SRES strobe over the SPI interface. See Section 19.1 on page 40 for furtherdetails.Parameter Min Typ Max Unit Condition/Note<strong>Power</strong> ramp-up time 5 ms From 0 V until reaching 1.8 V<strong>Power</strong> off time 1 ms Minimum time between power-on and power-offTable 12: <strong>Power</strong>-on Reset RequirementsSWRS040B Page 15 of 92

CC25005 Pin ConfigurationSIGNDDGUARDRBIASGND20 19 18 17 16SCLK 1SO (GDO1) 2GDO2 3DVDD 4DCOUPL 515 AVDD14 AVDD13 <strong>RF</strong>_N12 <strong>RF</strong>_P11 AVDD6GDO0 (ATEST)7CSn8XOSC_Q19AVDD10XOSC_Q2GNDExposed dieattach padFigure 1: Pinout Top ViewNote: The exposed die attach pad must be connected to a solid ground plane as this is the mainground connection for the chip.SWRS040B Page 16 of 92

CC2500Pin # Pin name Pin type Description1 SCLK Digital Input Serial configuration interface, clock input2 SO (GDO1) Digital Output Serial configuration interface, data output.Optional general output pin when CSn is high3 GDO2 Digital Output Digital output pin for general use:• Test signals• FIFO status signals• Clear Channel Indicator• Clock output, down-divided from XOSC• Serial output RX data4 DVDD <strong>Power</strong> (Digital) 1.8 - 3.6 V digital power supply for digital I/O’s and for the digital corevoltage regulator5 DCOUPL <strong>Power</strong> (Digital) 1.6 - 2.0 V digital power supply output for decoupling.6 GDO0(ATEST)Digital I/ONOTE: This pin is intended for use with the CC2500 only. It can not beused to provide supply voltage to other devices.Digital output pin for general use:• Test signals• FIFO status signals• Clear Channel Indicator• Clock output, down-divided from XOSC• Serial output RX data• Serial input TX dataAlso used as analog test I/O for prototype/production testing7 CSn Digital Input Serial configuration interface, chip select8 XOSC_Q1 Analog I/O Crystal oscillator pin 1, or external clock input9 AVDD <strong>Power</strong> (Analog) 1.8 - 3.6 V analog power supply connection10 XOSC_Q2 Analog I/O Crystal oscillator pin 211 AVDD <strong>Power</strong> (Analog) 1.8 - 3.6 V analog power supply connection12 <strong>RF</strong>_P <strong>RF</strong> I/O Positive <strong>RF</strong> input signal to LNA in receive modePositive <strong>RF</strong> output signal from PA in transmit mode13 <strong>RF</strong>_N <strong>RF</strong> I/O Negative <strong>RF</strong> input signal to LNA in receive modeNegative <strong>RF</strong> output signal from PA in transmit mode14 AVDD <strong>Power</strong> (Analog) 1.8 - 3.6 V analog power supply connection15 AVDD <strong>Power</strong> (Analog) 1.8 - 3.6 V analog power supply connection16 GND Ground (Analog) Analog ground connection17 RBIAS Analog I/O External bias resistor for reference current18 DGUARD <strong>Power</strong> (Digital) <strong>Power</strong> supply connection for digital noise isolation19 GND Ground (Digital) Ground connection for digital noise isolation20 SI Digital Input Serial configuration interface, data inputTable 13: Pinout OverviewSWRS040B Page 17 of 92

CC25006 Circuit DescriptionRADIO CONTROL<strong>RF</strong>_P<strong>RF</strong>_NLNAPARC OSCBIAS090ADCADCXOSCDEMODULATO<strong>RF</strong>REQSYNTHMODULATO<strong>RF</strong>EC / INTERLEAVERPACKET HANDLERRXFIFOTXFIFODIGITAL INTE<strong>RF</strong>ACE TO MCUSCLKSO (GDO1)SICSnGDO0 (ATEST)GDO2RBIAS XOSC_Q1 XOSC_Q2Figure 2: CC2500 Simplified Block DiagramA simplified block diagram of CC2500 is shownin Figure 2.CC2500 features a low-IF receiver. Thereceived <strong>RF</strong> signal is amplified by the lownoiseamplifier (LNA) and down-converted inquadrature (I and Q) to the intermediatefrequency (IF). At IF, the I/Q signals aredigitised by the ADCs. Automatic gain control(AGC), fine channel filtering, demodulationbit/packet synchronization are performeddigitally.The transmitter part of CC2500 is based ondirect synthesis of the <strong>RF</strong> frequency.The frequency synthesizer includes acompletely on-chip LC VCO and a 90 degreesphase shifter for generating the I and Q LOsignals to the down-conversion mixers inreceive mode.A crystal is to be connected to XOSC_Q1 andXOSC_Q2. The crystal oscillator generates thereference frequency for the synthesizer, aswell as clocks for the ADC and the digital part.A 4-wire SPI serial interface is used forconfiguration and data buffer access.The digital baseband includes support forchannel configuration, packet handling, anddata buffering.7 Application CircuitOnly a few external components are requiredfor using the CC2500. The recommendedapplication circuit is shown in Figure 3. Theexternal components are described in Table14, and typical values are given in Table 15.Bias ResistorThe bias resistor R171 is used to set anaccurate bias current.Balun and <strong>RF</strong> MatchingThe components between the <strong>RF</strong>_N/<strong>RF</strong>_P pinsand the point where the two signals are joinedtogether (C122, C132, L121, and L131) form aSWRS040B Page 18 of 92

CC2500balun that converts the differential <strong>RF</strong> signalon CC2500 to a single-ended <strong>RF</strong> signal. C121and C131 are needed for DC blocking.Together with an appropriate LC network, thebalun components also transform theimpedance to match a 50 Ω antenna (orcable). Suggested values are listed in Table15.The balun and LC filter component values andtheir placement are important to keep theperformance optimized. It is highlyrecommended to follow the CC2500EMreference design ([4]).CrystalThe crystal oscillator uses an external crystalwith two loading capacitors (C81 and C101).See Section 26 on page 51 for details.<strong>Power</strong> Supply DecouplingThe power supply must be properly decoupledclose to the supply pins. Note that decouplingcapacitors are not shown in the applicationcircuit. The placement and the size of thedecoupling capacitors are very important toachieve the optimum performance. TheCC2500EM reference design ([4]) should befollowed closely.ComponentC51C81/C101C121/C131C122/C132C123/C124L121/L131L122R171XTALDescriptionDecoupling capacitor for on-chip voltage regulator to digital partCrystal loading capacitors, see Section 26 on page 51 for details<strong>RF</strong> balun DC blocking capacitors<strong>RF</strong> balun/matching capacitors<strong>RF</strong> LC filter/matching capacitors<strong>RF</strong> balun/matching inductors (inexpensive multi-layer type)<strong>RF</strong> LC filter inductor (inexpensive multi-layer type)Resistor for internal bias current reference26-27 MHz crystal, see Section 26 on page 51 for detailsTable 14: Overview of External Components (excluding supply decoupling capacitors)1.8V-3.6V power supplyR171SIDigital IntefaceSCLKSO(GDO1)GDO2(optional)C511 SCLKSI 20GND 19DGUARD 18RBIAS 17GND 162 SO (GDO1)AVDD 143 GDO24 DVDD5 DCOUPLCC2500DIE ATTACH PAD:6 GDO07 CSn8 XOSC_Q19 AVDD10 XOSC_Q2AVDD 15<strong>RF</strong>_N 13<strong>RF</strong>_P 12AVDD 11L131C131 C132C121L121C122L122C123Antenna(50 Ohm)C124GDO0(optional)CSnXTALAlternative:Folded dipole PCBantenna (no externalcomponents needed)C81C101Figure 3: Typical Application and Evaluation Circuit (excluding supply decoupling capacitors)SWRS040B Page 19 of 92

CC2500Component Value ManufacturerC51 100 nF ±10%, 0402 X5R Murata GRM15 seriesC81 27 pF ±5%, 0402 NP0 Murata GRM15 seriesC101 27 pF ±5%, 0402 NP0 Murata GRM15 seriesC121 100 pF ±5%, 0402 NP0 Murata GRM15 seriesC122 1.0 pF ±0.25 pF, 0402 NP0 Murata GRM15 seriesC123 1.8 pF ±0.25 pF, 0402 NP0 Murata GRM15 seriesC124 1.5 pF ±0.25 pF, 0402 NP0 Murata GRM15 seriesC131 100 pF ±5%, 0402 NP0 Murata GRM15 seriesC132 1.0 pF ±0.25 pF, 0402 NP0 Murata GRM15 seriesL121 1.2 nH ±0.3 nH, 0402 monolithic Murata LQG15HS seriesL122 1.2 nH ±0.3 nH, 0402 monolithic Murata LQG15HS seriesL131 1.2 nH ±0.3 nH, 0402 monolithic Murata LQG15HS seriesR171 56 kΩ ±1%, 0402 Koa RK73 seriesXTAL 26.0 MHz surface mount crystal NDK, AT-41CD2Table 15: Bill Of Materials for the Application CircuitMeasurements have been performed withmulti-layer inductors from other manufacturers(e.g. Würth) and the measurement resultswere the same as when using the Murata part.The Gerber files for the CC2500EM referencedesign ([4]) are available from the TI website.Figure 4: CC2500EM Reference Design ([4])8 Configuration OverviewCC2500 can be configured to achieve optimumperformance for many different applications.Configuration is done using the SPI interface.The following key parameters can beprogrammed:• <strong>Power</strong>-down / power up mode• Crystal oscillator power-up / power-down• Receive / transmit mode• <strong>RF</strong> channel selection• Data rate• Modulation format• RX channel filter bandwidth• <strong>RF</strong> output power• Data buffering with separate 64-bytereceive and transmit FIFOs• Packet radio hardware support• Forward Error Correction (FEC) withinterleaving• Data Whitening• Wake-On-Radio (WOR)Details of each configuration register can befound in Section 32, starting on page 58.Figure 5 shows a simplified state diagram thatexplains the main CC2500 states, together withtypical usage and current consumption. Fordetailed information on controlling the CC2500state machine, and a complete state diagram,see Section 19, starting on page 40.SWRS040B Page 20 of 92

CC2500Default state when the radio is notreceiving or transmitting. Typ.current consumption: 1.5mA.Used for calibrating frequencysynthesizer upfront (enteringreceive or transmit mode can Manual freq.then be done quicker). synth. calibrationTransitional state. Typ. currentconsumption: 7.4mA.SCALSIDLESPWD or wake-on-radio (WOR)IdleCSn=0CSn=0SXOFFSRX or STX or SFSTXON or wake-on-radio (WOR)SleepCrystaloscillator off<strong>Low</strong>est power mode. Mostregister values are retained.Typ. current consumption400nA, or 900nA whenwake-on-radio (WOR) isenabled.All register values areretained. Typ. currentconsumption; 0.16mA.Frequency synthesizer is on,ready to start transmitting.Transmission starts veryquickly after receiving theSTX command strobe.Typ.current consumption: 7.4mA.Frequencysynthesizer onSFSTXONFrequencysynthesizer startup,optional calibration,settlingSTXFrequency synthesizer is turned on, can optionally becalibrated, and then settles to the correct frequency.Transitional state. Typ. current consumption: 7.4mA.SRX or wake-on-radio (WOR)STXTXOFF_MODE=01SFSTXON or RXOFF_MODE=01Typ. current consumption:11.1mA at -12dBm output,15.1mA at -6dBm output,21.2mA at 0dBm output.Transmit modeSTX or RXOFF_MODE=10SRX or TXOFF_MODE=11Receive modeTyp. currentconsumption:from 13.3mA (stronginput signal) to 16.6mA(weak input signal).In FIFO-based modes,transmission is turned offand this state entered if theTX FIFO becomes empty inthe middle of a packet. Typ.current consumption: 1.5mA.TX FIFOunderflowTXOFF_MODE=00RXOFF_MODE=00Optional transitional state. Typ.current consumption: 7.4mA.Optional freq.synth. calibrationRX FIFOoverflowIn FIFO-based modes,reception is turned off andthis state entered if the RXFIFO overflows. Typ.current consumption:1.5mA.SFTXSFRXIdleFigure 5: Simplified State Diagram with Typical Usage and Current Consumption at 250 kBaudData Rate and MDMCFG2.DEM_DCFILT_OFF=1 (current optimized)9 Configuration SoftwareCC2500 can be configured using the Smart<strong>RF</strong> ®Studio software [5]. The Smart<strong>RF</strong> ® Studiosoftware is highly recommended for obtainingoptimum register settings, and for evaluatingperformance and functionality. A screenshot ofthe Smart<strong>RF</strong> ® Studio user interface for CC2500is shown in Figure 6.After chip reset, all the registers have defaultvalues as shown in the tables in Section 32.The optimum register setting might differ fromthe default value. After a reset all registers thatshall be different from the default valuetherefore needs to be programmed through theSPI interface.SWRS040B Page 21 of 92

CC2500Figure 6: Smart<strong>RF</strong> ® Studio [5] User Interface10 4-wire Serial Configuration and Data InterfaceCC2500 is configured via a simple 4-wire SPIcompatibleinterface (SI, SO, SCLK and CSn)where CC2500 is the slave. This interface isalso used to read and write buffered data. Alltransfers on the SPI interface are done mostsignificant bit first.All transactions on the SPI interface start witha header byte containing a R/W bit, a burstaccess bit (B), and a 6-bit address (A 5 – A 0 ).The CSn pin must be kept low during transferson the SPI bus. If CSn goes high during thetransfer of a header byte or during read/writefrom/to a register, the transfer will becancelled. The timing for the address and datatransfer on the SPI interface is shown inFigure 7 with reference to Table 16.When CSn is pulled low, the MCU must waituntil CC2500 SO pin goes low before starting totransfer the header byte. This indicates thatthe crystal is running. Unless the chip was inthe SLEEP or XOFF states, the SO pin willalways go low immediately after taking CSnlow.SWRS040B Page 22 of 92

CC2500Figure 7: Configuration Register Write and Read OperationsParameter Description Min Max Unitsf SCLKSCLK frequency100 ns delay inserted between address byte and data byte (single access), or betweenaddress and data, and between each data byte (burst access).SCLK frequency, single accessNo delay between address and data byteSCLK frequency, burst accessNo delay between address and data byte, or between data bytes- 10 MHz9 MHz6.5 MHzt sp,pd CSn low to positive edge on SCLK, in power-down mode 150 µst sp CSn low to positive edge on SCLK, in active mode 20 - nst ch Clock high 50 - nst cl Clock low 50 - nst rise Clock rise time - 5 nst fall Clock fall time - 5 nst sdSetup data (negative SCLK edge) topositive edge on SCLK(t sd applies between address and data bytes, andbetween data bytes)<strong>Single</strong> access 55 - nsBurst access 76 - nst hd Hold data after positive edge on SCLK 20 - nst ns Negative edge on SCLK to CSn high 20 - nsTable 16: SPI Interface Timing RequirementsNote: The minimum t sp,pd figure in Table 16 can be used in cases where the user does not read theCHIP_RDYn signal. CSn low to positive edge on SCLK when the chip is woken from power-downdepends on the start-up time of the crystal being used. The 150 us in Table 16 is the crystal oscillatorstart-up time measured on CC2500EM reference design ([4]) using crystal AT-41CD2 from NDK.10.1 <strong>Chip</strong> Status ByteWhen the header byte, data byte or, commandstrobe is sent on the SPI interface, the chipstatus byte is sent by the CC2500 on the SOpin. The status byte contains key statussignals, useful for the MCU. The first bit, s7, isthe CHIP_RDYn signal; this signal must go lowbefore the first positive edge of SCLK. TheCHIP_RDYn signal indicates that the crystal isrunning.Bits 6, 5, and 4 comprise the STATE value.This value reflects the state of the chip. TheXOSC and power to the digital core is on inthe IDLE state, but all other modules are inpower down. The frequency and channelSWRS040B Page 23 of 92

CC2500configuration should only be updated when thechip is in this state. The RX state will be activewhen the chip is in receive mode. Likewise, TXis active when the chip is transmitting.The last four bits (3:0) in the status bytecontains FIFO_BYTES_AVAILABLE. For readoperations (the R/W bit in the header byte isset to 1), the FIFO_BYTES_AVAILABLE fieldcontains the number of bytes available forreading from the RX FIFO. For writeoperations (the R/W bit in the header byte isset to 0), the FIFO_BYTES_AVAILABLE fieldcontains the number of bytes that can bewritten to the TX FIFO. WhenFIFO_BYTES_AVAILABLE=15, 15 or morebytes are available/free.Table 17 gives a status byte summary.Bits Name Description7 CHIP_RDYn Stays high until power and crystal have stabilized. Should always be low when usingthe SPI interface.6:4 STATE[2:0] Indicates the current main state machine modeValue State Description000 IDLE Idle state(Also reported for some transitional statesinstead of SETTLING or CALIBRATE)001 RX Receive mode010 TX Transmit mode011 FSTXON Frequency synthesizer is on, ready to starttransmitting100 CALIBRATE Frequency synthesizer calibration is running101 SETTLING PLL is settling110 RXFIFO_OVE<strong>RF</strong>LOW RX FIFO has overflowed. Read out anyuseful data, then flush the FIFO with SFRX111 TXFIFO_UNDE<strong>RF</strong>LOW TX FIFO has underflowed. Acknowledge withSFTX3:0 FIFO_BYTES_AVAILABLE[3:0] The number of bytes available in the RX FIFO or free bytes in the TX FIFOTable 17: Status Byte Summary10.2 Register AccessThe configuration registers of the CC2500 arelocated on SPI addresses from 0x00 to 0x2E.Table 35 on page 59 lists all configurationregisters. It is highly recommended to useSmart<strong>RF</strong> ® Studio [5] to generate optimumregister settings. The detailed description ofeach register is found in Section 32.1, startingon page 62. All configuration registers can beboth written to and read. The R/W bit controlsif the register should be written to or read.When writing to registers, the status byte issent on the SO pin each time a header byte ordata byte is transmitted on the SI pin. Whenreading from registers, the status byte is senton the SO pin each time a header byte istransmitted on the SI pin.Registers with consecutive addresses can beaccessed in an efficient way by setting theburst bit (B) in the header byte. The addressbits (A 5 – A 0 ) set the start address in aninternal address counter. This counter isincremented by one each new byte (every 8clock pulses). The burst access is either aread or a write access and must be terminatedby setting CSn high.For register addresses in the range 0x30-0x3D, the burst bit is used to select betweenstatus registers, burst bit is one, and commandstrobes, burst bit is zero (see Section 10.4below). Because of this, burst access is notavailable for status registers and they must beaccessed one at a time. The status registerscan only be read.10.3 SPI ReadWhen reading register fields over the SPIinterface while the register fields are updatedSWRS040B Page 24 of 92

CC2500by the radio hardware (e.g. MARCSTATE orTXBYTES), there is a small, but finite,probability that a single read from the registeris being corrupt. As an example, theprobability of any single read from TXBYTESbeing corrupt, assuming the maximum datarate is used, is approximately 80 ppm. Refer tothe CC2500 Errata Notes [1] for more details.10.4 Command StrobesCommand strobes may be viewed as singlebyte instructions to CC2500. By addressing acommand strobe register, internal sequenceswill be started. These commands are used todisable the crystal oscillator, enable receivemode, enable wake-on-radio etc. The 13command strobes are listed in Table 34 onpage 58.The command strobe registers are accessedby transferring a single header byte (no data isbeing transferred). That is, only the R/W bit,the burst access bit (set to 0), and the sixaddress bits (in the range 0x30 through 0x3D)are written. TheR/W bit canbe either one or zero and will determine howthe FIFO_BYTES_AVAILABLE field in thestatus byte should be interpreted.When writing command strobes, the statusbyte is sent on the SO pin.A command strobe may be followed by anyother SPI access without pulling CSn high.However, if an SRES strobe is being issued,one will have to wait for SO to go low againbefore the next header byte can be issued asshown in Figure 8. The command strobes areexecuted immediately, with the exception ofthe SPWD and the SXOFF strobes that areexecuted when CSn goes high.The TX FIFO is write-only, while the RX FIFOis read-only.The burst bit is used to determine if the FIFOaccess is a single byte access or a burstaccess. The single byte access methodexpects a header byte with the burst bit set tozero and one data byte. After the data byte anew header byte is expected; hence, CSn canremain low. The burst access method expectsone header byte and then consecutive databytes until terminating the access by settingCSn high.The following header bytes access the FIFOs:• 0x3F: <strong>Single</strong> byte access to TX FIFO• 0x7F: Burst access to TX FIFO• 0xBF: <strong>Single</strong> byte access to RX FIFO• 0xFF: Burst access to RX FIFOWhen writing to the TX FIFO, the status byte(see Section 10.1) is output for each new databyte on SO, as shown in Figure 7. This statusbyte can be used to detect TX FIFO underflowwhile writing data to the TX FIFO. Note thatthe status byte contains the number of bytesfree before writing the byte in progress to theTX FIFO. When the last byte that fits in the TXFIFO is transmitted on SI, the status bytereceived concurrently on SO will indicate thatone byte is free in the TX FIFO.The TX FIFO may be flushed by issuing aSFTX command strobe. Similarly, a SFRXcommand strobe will flush the RX FIFO. ASFTX or SFRX command strobe can only beissued in the IDLE, TXFIFO_UNDERLOW orRXFIFO_OVE<strong>RF</strong>LOW states. Both FIFOs areflushed when going to the SLEEP state.Figure 9 gives a brief overview of differentregister access types possible.Figure 8: SRES Command Strobe10.5 FIFO AccessThe 64-byte TX FIFO and the 64-byte RXFIFO are accessed through the 0x3F address.When the R/W bit is zero, the TX FIFO isaccessed, and the RX FIFO is accessed whenthe R/W bit is one.10.6 PATABLE AccessThe 0x3E address is used to access thePATABLE, which is used for selecting PApower control settings. The PATABLE is an 8-byte table, but not all entries into this table areused. The entries to use are selected by the 3-bit value FREND0.PA_POWER.• When using 2-FSK, GFSK, or MSKmodulation only the first entry into thistable is used (index 0).SWRS040B Page 25 of 92

CC2500• When using OOK modulation the first twoentries into this table are used (index 0and index 1).Since the PATABLE is an 8-byte table, thetable is written and read from the lowestsetting (0) to the highest (7), one byte at atime. An index counter is used to control theaccess to the table. This counter isincremented each time a byte is read orwritten to the table, and set to the lowest indexwhen CSn is high. When the highest value isreached the counter restarts at 0.The access to the PATABLE is either singlebyte or burst access depending on the burstbit. When using burst access the index counterwill count up; when reaching 7 the counter willrestart at 0. The read/write bit controls whetherthe access is a write access (R/W=0) or a readaccess (R/W=1).If one byte is written to the PATABLE and thisvalue is to be read out then CSn must be sethigh before the read access in order to set theindex counter back to zero.Note that the content of the PATABLE is lostwhen entering the SLEEP state, except for thefirst byte (index 0).See Section 24 on page 47 for output powerprogramming details.Figure 9: Register Access Types11 Microcontroller Interface and Pin ConfigurationIn a typical system, CC2500 will interface to amicrocontroller. This microcontroller must beable to:• Program CC2500 into different modes• Read and write buffered data• Read back status information via the 4-wireSPI-bus configuration interface (SI, SO,SCLK and CSn)11.1 Configuration InterfaceThe microcontroller uses four I/O pins for theSPI configuration interface (SI, SO, SCLK andCSn). The SPI is described in Section 10 onpage 22.11.2 General Control and Status PinsThe CC2500 has two dedicated configurablepins (GDO0 and GDO2) and one shared pin(GDO1) that can output internal statusinformation useful for control software. Thesepins can be used to generate interrupts on theMCU. See Section 28 on page 52 for moredetails on the signals that can be programmed.GDO1 is shared with the SO pin in the SPIinterface. The default setting for GDO1/SO is 3-state output. By selecting any other of theprogramming options the GDO1/SO pin willbecome a generic pin. When CSn is low, thepin will always function as a normal SO pin.In the synchronous and asynchronous serialmodes, the GDO0 pin is used as a serial TXdata input pin while in transmit mode.SWRS040B Page 26 of 92

CC2500The GDO0 pin can also be used for an on-chipanalog temperature sensor. By measuring thevoltage on the GDO0 pin with an external ADC,the temperature can be calculated.Specifications for the temperature sensor arefound in Section 4.7 on page 15.With default PTEST register setting (0x7F) thetemperature sensor output is only availablewhen the frequency synthesizer is enabled(e.g. the MANCAL, FSTXON, RX and TXstates). It is necessary to write 0xBF to thePTEST register to use the analog temperaturesensor in the IDLE state. Before leaving theIDLE state, the PTEST register should berestored to its default value (0x7F).State changes are commanded as follows:When CSn is high the SI and SCLK is set tothe desired state according to Table 18. WhenCSn goes low the state of SI and SCLK islatched and a command strobe is generatedinternally according to the control coding. It isonly possible to change state with thisfunctionality. That means that for instance RXwill not be restarted if SI and SCLK are set toRX and CSn toggles. When CSn is low the SIand SCLK has normal SPI functionality.All pin control command strobes are executedimmediately, except the SPWD strobe, which isdelayed until CSn goes high.11.3 Optional Radio Control FeatureThe CC2500 has an optional way of controllingthe radio, by reusing SI, SCLK and CSn fromthe SPI interface. This feature allows for asimple three-pin control of the major states ofthe radio: SLEEP, IDLE, RX and TX.This optional functionality is enabled with theMCSM0.PIN_CTRL_EN configuration bit.CSn SCLK SI Function1 X X <strong>Chip</strong> unaffected by SCLK/SI↓ 0 0 Generates SPWD strobe↓ 0 1 Generates STX strobe↓ 1 0 Generates SIDLE strobe↓ 1 1 Generates SRX strobe0SPImodeSPImodeSPI mode (wakes up intoIDLE if in SLEEP/XOFF)Table 18: Optional Pin Control Coding12 Data Rate ProgrammingThe data rate used when transmitting, or thedata rate expected in receive is programmedby the MDMCFG3.DRATE_M and theMDMCFG4.DRATE_E configuration registers.The data rate is given by the formula below.As the formula shows, the programmed datarate depends on the crystal frequency.R( 256 + DRATE _ M )DATA=282⋅ 2DRATE _ E⋅ fXOSCThe following approach can be used to findsuitable values for a given data rate:⎢ ⎛ RDRATE _ E = ⎢log2⎜⎢⎣⎝ fDRATE _ M =fRDATA⋅ 2⋅ 2XOSC2028DATADRATE _ EXOSC⋅ 2⎞⎥⎟⎥⎠⎥⎦− 256If DRATE_M is rounded to the nearest integerand becomes 256, increment DRATE_E anduse DRATE_M=0.The data rate can be set from 1.2 kBaud to500 kBaud with the minimum step size of:Min DataRate[kBaud]TypicalData Rate[kBaud]Max DataRate[kBaud]Data RateStep Size[kBaud]0.8 1.2/2.4 3.17 0.00623.17 4.8 6.35 0.01246.35 9.6 12.7 0.024812.7 19.6 25.4 0.049625.4 38.4 50.8 0.099250.8 76.8 101.6 0.1984101.6 153.6 203.1 0.3967203.1 250 406.3 0.7935406.3 500 500 1.5869Table 19: Data Rate Step SizeSWRS040B Page 27 of 92

CC250013 Receiver Channel Filter BandwidthIn order to meet different channel widthrequirements, the receiver channel filter isprogrammable. The MDMCFG4.CHANBW_E andMDMCFG4.CHANBW_M configuration registerscontrol the receiver channel filter bandwidth,which scales with the crystal oscillatorfrequency. The following formula gives therelation between the register settings and thechannel filter bandwidth:BWchannelfXOSC=8 ⋅ (4 + CHANBW_M )·2CHANBW_EFor best performance, the channel filterbandwidth should be selected so that thesignal bandwidth occupies at most 80% of thechannel filter bandwidth. The channel centretolerance due to crystal accuracy should alsobe subtracted from the signal bandwidth. Thefollowing example illustrates this:With the channel filter bandwidth set to 600kHz, the signal should stay within 80% of 600kHz, which is 480 kHz. Assuming 2.44 GHzfrequency and ±20 ppm frequency uncertaintyfor both the transmitting device and thereceiving device, the total frequencyuncertainty is ±40 ppm of 2.44 GHz, which is±98 kHz. If the whole transmitted signalbandwidth is to be received within 480 kHz,the transmitted signal bandwidth should bemaximum 480 kHz – 2·98 kHz, which is 284kHz.The CC2500 supports the following channelfilter bandwidths:MDMCFG4.MDMCFG4.CHANBW_ECHANBW_M 00 01 10 1100 812 406 203 10201 650 325 162 8110 541 270 135 6811 464 232 116 58Table 20: Channel Filter Bandwidths [kHz](assuming a 26 MHz crystal)14 Demodulator, Symbol Synchronizer and Data DecisionCC2500 contains an advanced and highlyconfigurable demodulator. Channel filteringand frequency offset compensation isperformed digitally. To generate the RSSI level(see Section 17.3 for more information) thesignal level in the channel is estimated. Datafiltering is also included for enhancedperformance.14.1 Frequency Offset CompensationWhen using 2-FSK, GFSK, or MSKmodulation, the demodulator will compensatefor the offset between the transmitter andreceiver frequency, within certain limits, byestimating the centre of the received data.This value is available in the FREQEST statusregister. Writing the value from FREQEST intoFSCTRL0.FREQOFF the frequencysynthesizer is automatically adjustedaccording to the estimated frequency offset.The tracking range of the algorithm isselectable as fractions of the channelbandwidth with the FOCCFG.FOC_LIMITconfiguration register.If the FOCCFG.FOC_BS_CS_GATE bit is set,the offset compensator will freeze until carriersense asserts. This may be useful when theradio is in RX for long periods with no traffic,since the algorithm may drift to the boundarieswhen trying to track noise.The tracking loop has two gain factors, whichaffects the settling time and noise sensitivity ofthe algorithm. FOCCFG.FOC_PRE_K sets thegain before the sync word is detected, andFOCCFG.FOC_POST_K selects the gain afterthe sync word has been found.Note that frequency offset compensation is notsupported for OOK modulation.14.2 Bit SynchronizationThe bit synchronization algorithm extracts theclock from the incoming symbols. Thealgorithm requires that the expected data rateis programmed as described in Section 12 onpage 27. Re-synchronization is performedcontinuously to adjust for error in the incomingsymbol rate.SWRS040B Page 28 of 92

CC250014.3 Byte SynchronizationByte synchronization is achieved by acontinuous sync word search. The sync wordis a 16 bit configurable field (can be repeatedto get a 32 bit) that is automatically inserted atthe start of the packet by the modulator intransmit mode. The demodulator uses thisfield to find the byte boundaries in the streamof bits. The sync word will also function as asystem identifier, since only packets with thecorrect predefined sync word will be received ifthe sync word detection in RX is enabled inregister MDMCFG2 (see Section 17.1). Thesync word detector correlates against theuser-configured 16 or 32 bit sync word. Thecorrelation threshold can be set to 15/16,16/16, or 30/32 bits match. The sync word canbe further qualified using the preamble qualityindicator mechanism described below and/or acarrier sense condition. The sync word isconfigured through the SYNC1 and SYNC0registers.In order to make false detections of syncwords less likely, a mechanism calledpreamble quality indication (PQI) can be usedto qualify the sync word. A threshold value forthe preamble quality must be exceeded inorder for a detected sync word to be accepted.See Section 17.2 on page 35 for more details.15 Packet Handling Hardware SupportThe CC2500 has built-in hardware support forpacket oriented radio protocols.In transmit mode, the packet handler can beconfigured to add the following elements to thepacket stored in the TX FIFO:• A programmable number of preamblebytes• A two byte synchronization (sync) word.Can be duplicated to give a 4-byte syncword (recommended). It is not possible toonly insert preamble or only insert a syncword.• A CRC checksum computed over the datafieldThe recommended setting is 4-byte preambleand 4-byte sync word, except for 500 kBauddata rate where the recommended preamblelength is 8 bytes.In addition, the following can be implementedon the data field and the optional 2-byte CRCchecksum:• Whitening of the data with a PN9sequence.• Forward error correction by the use ofinterleaving and coding of the data(convolutional coding).In receive mode, the packet handling supportwill de-construct the data packet byimplementing the following (if enabled):• Preamble detection• Sync word detection• CRC computation and CRC check• One byte address check• Packet length check (length byte checkedagainst a programmable maximum length)• De-whitening• De-interleaving and decodingOptionally, two status bytes (see Table 21 andTable 22) with RSSI value, Link QualityIndication, and CRC status can be appendedin the RX FIFO.Bit Field name Description7:0 RSSI RSSI valueTable 21: Received Packet Status Byte 1(first byte appended after the data)Bit Field name Description7 CRC_OK 1: CRC for received data OK (orCRC disabled)0: CRC error in received data6:0 LQI The Link Quality Indicatorestimates how easily a receivedsignal can be demodulatedTable 22: Received Packet Status Byte 2(second byte appended after the data)Note that register fields that control the packethandling features should only be altered whenCC2500 is in the IDLE state.SWRS040B Page 29 of 92

CC250015.1 Data WhiteningFrom a radio perspective, the ideal over the airdata are random and DC free. This results inthe smoothest power distribution over theoccupied bandwidth. This also gives theregulation loops in the receiver uniformoperation conditions (no data dependencies).Real world data often contain long sequencesof zeros and ones. Performance can then beimproved by whitening the data beforetransmitting, and de-whitening the data in thereceiver. With CC2500, this can be doneautomatically by settingPKTCTRL0.WHITE_DATA=1. All data, exceptthe preamble and the sync word, are thenXOR-ed with a 9-bit pseudo-random (PN9)sequence before being transmitted as shownin Figure 10. At the receiver end, the data areXOR-ed with the same pseudo-randomsequence. This way, the whitening is reversed,and the original data appear in the receiver.The PN9 sequence is reset to all 1’s.Data whitening can only be used whenPKTCTRL0.CC2400_EN=0 (default).Figure 10: Data Whitening in TX Mode15.2 Packet FormatThe format of the data packet can beconfigured and consists of the following items(see Figure 11):• Preamble• Synchronization word• Length byte or constant programmablepacket length• Optional address byte• Payload• Optional 2 byte CRCOptional data whiteningOptionally FEC encoded/decodedOptional CRC-16 calculationLegend:Inserted automatically in TX,processed and removed in RX.Preamble bits(1010...1010)Sync word8 x n bits 16/32 bitsLength field8bitsAddress field8bitsData fieldCRC-168 x n bits 16 bitsFigure 11: Packet FormatOptional user-provided fields processed in TX,processed but not removed in RX.Unprocessed user data (apart from FECand/or whitening)SWRS040B Page 30 of 92

CC2500The preamble pattern is an alternatingsequence of ones and zeros (101010101…).The minimum length of the preamble isprogrammable. When enabling TX, themodulator will start transmitting the preamble.When the programmed number of preamblebytes has been transmitted, the modulator willsend the sync word and then data from the TXFIFO if data is available. If the TX FIFO isempty, the modulator will continue to sendpreamble bytes until the first byte is written tothe TX FIFO. The modulator will then send thesync word and then the data bytes. Thenumber of preamble bytes is programmed withthe MDMCFG1.NUM_PREAMBLE value.The synchronization word is a two-byte valueset in the SYNC1 and SYNC0 registers. Thesync word provides byte synchronization of theincoming packet. A one-byte sync word can beemulated by setting the SYNC1 value to thepreamble pattern. It is also possible to emulatea 32 bit sync word by usingMDMCFG2.SYNC_MODE=3 or 7. The sync wordwill then be repeated twice.CC2500 supports both fixed packet lengthprotocols and variable packet length protocols.Variable or fixed packet length mode can beused for packets up to 255 bytes. For longerpackets, infinite packet length mode must beused.Fixed packet length mode is selected bysetting PKTCTRL0.LENGTH_CONFIG=0. Thedesired packet length is set by the PKTLENregister.In variable packet length mode,PKTCTRL0.LENGTH_CONFIG=1, the packetlength is configured by the first byte after thesync word. The packet length is defined as thepayload data, excluding the length byte andthe optional CRC. The PKTLEN register isused to set the maximum packet lengthallowed in RX. Any packet received with alength byte with a value greater than PKTLENwill be discarded.With PKTCTRL0.LENGTH_CONFIG=2, thepacket length is set to infinite and transmissionand reception will continue until turned offmanually. As described in the next section, thiscan be used to support packet formats withdifferent length configuration than nativelysupported by CC2500. One should make surethat TX mode is not turned off during thetransmission of the first half of any byte. Referto the CC2500 Errata Notes [1] for moredetails.Note that the minimum packet lengthsupported (excluding the optional length byteand CRC) is one byte of payload data.15.2.1 Arbitrary Length Field ConfigurationThe packet length register, PKTLEN, can bereprogrammed during receive and transmit. Incombination with fixed packet length mode(PKTCTRL0.LENGTH_CONFIG=0) this opensthe possibility to have a different length fieldconfiguration than supported for variablelength packets (in variable packet length modethe length byte is the first byte after the syncword). At the start of reception, the packetlength is set to a large value. The MCU readsout enough bytes to interpret the length field inthe packet. Then the PKTLEN value is setaccording to this value. The end of packet willoccur when the byte counter in the packethandler is equal to the PKTLEN register. Thus,the MCU must be able to program the correctlength, before the internal counter reaches thepacket length.15.2.2 Packet Length > 256 bytesAlso the packet automation control register,PKTCTRL0, can be reprogrammed during TXand RX. This opens the possibility to transmitand receive packets that are longer than 256bytes and still be able to use the packethandling hardware support. At the start of thepacket, the infinite packet length mode(PKTCTRL0.LENGTH_CONFIG=2) must beactive. On the TX side, the PKTLEN register isset to mod(length,256). On the RX side theMCU reads out enough bytes to interpret thelength field in the packet and sets the PKTLENregister to mod(length,256). When less than256 bytes remains of the packet the MCUdisables infinite packet length mode andactivates fixed packet length mode. When theinternal byte counter reaches the PKTLENvalue, the transmission or reception ends (theradio enters the state determined byTXOFF_MODE or RXOFF_MODE). AutomaticCRC appending/checking can also be used(by setting PKTCTRL0.CRC_EN=1).When for example a 600-byte packet is to betransmitted, the MCU should do the following(see also Figure 12):• Set PKTCTRL0.LENGTH_CONFIG=2.SWRS040B Page 31 of 92

CC2500• Pre-program the PKTLEN register tomod(600,256)=88.• Transmit at least 345 bytes, for exampleby filling the 64-byte TX FIFO six times(384 bytes transmitted).• Set PKTCTRL0.LENGTH_CONFIG=0.• The transmission ends when the packetcounter reaches 88. A total of 600 bytesare transmitted.Internal byte counter in packet handler counts from 0 to 255 and then starts at 0 again0,1,..........,88,....................255,0,........,88,..................,255,0,........,88,..................,255,0,.......................Infinite packet length enabledFixed packet lengthenabled when less than256 bytes remains ofpacket600 bytes transmitted andreceivedLength field transmitted and received. Rx and Tx PKTLEN value set to mod(600,256) = 88Figure 12: Packet Length > 25615.3 Packet Filtering in Receive ModeCC2500 supports three different types ofpacket-filtering: address filtering, maximumlength filtering and CRC filtering.15.3.1 Address FilteringSetting PKTCTRL1.ADR_CHK to any othervalue than zero enables the packet addressfilter. The packet handler engine will comparethe destination address byte in the packet withthe programmed node address in the ADDRregister and the 0x00 broadcast address whenPKTCTRL1.ADR_CHK=10 b or both 0x00 and0xFF broadcast addresses whenPKTCTRL1.ADR_CHK=11 b . If the receivedaddress matches a valid address, the packet isreceived and written into the RX FIFO. If theaddress match fails, the packet is discardedand receive mode restarted (regardless of theMCSM1.RXOFF_MODE setting).If the received address matches a validaddress when using infinite packet lengthmode and address filtering is enabled, 0xFFwill be written into the RX FIFO followed by theaddress byte and then the payload data.15.3.2 Maximum Length FilteringIn variable packet length mode,PKTCTRL0.LENGTH_CONFIG=1, thePKTLEN.PACKET_LENGTH register value isused to set the maximum allowed packetlength. If the received length byte has a largervalue than this, the packet is discarded andreceive mode restarted (regardless of theMCSM1.RXOFF_MODE setting).15.3.3 CRC FilteringThe filtering of a packet when CRC check failsis enabled by settingPKTCTRL1.CRC_AUTOFLUSH=1. The CRCauto flush function will flush the entire RXFIFO if the CRC check fails. After auto flushingthe RX FIFO, the next state depends on theMCSM1.RXOFF_MODEsetting.PKTCTRL0.CC2400_EN must be 0 (default)for the CRC auto flush function to workcorrectly.When using the auto flush function, themaximum packet length is 63 bytes in variablepacket length mode and 64 bytes in fixedpacket length mode. Note that the maximumallowed packet length is reduced by two byteswhen PKTCTRL1.APPEND_STATUS isenabled, to make room in the RX FIFO for thetwo status bytes appended at the end of thepacket. Since the entire RX FIFO is flushedwhen the CRC check fails, the previouslyreceived packet must be read out of the FIFObefore receiving the current packet. The MCUmust not read from the current packet until theCRC has been checked as OK.15.4 CRC CheckThere are two different CRC implementations.PKTCTRL0.CC2400_EN selects between the2 options. The CRC check is different for the 2SWRS040B Page 32 of 92