NW 17th Avenue Bridge Rehabilitation Over the Miami River, Miami ...

NW 17th Avenue Bridge Rehabilitation Over the Miami River, Miami ...

NW 17th Avenue Bridge Rehabilitation Over the Miami River, Miami ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

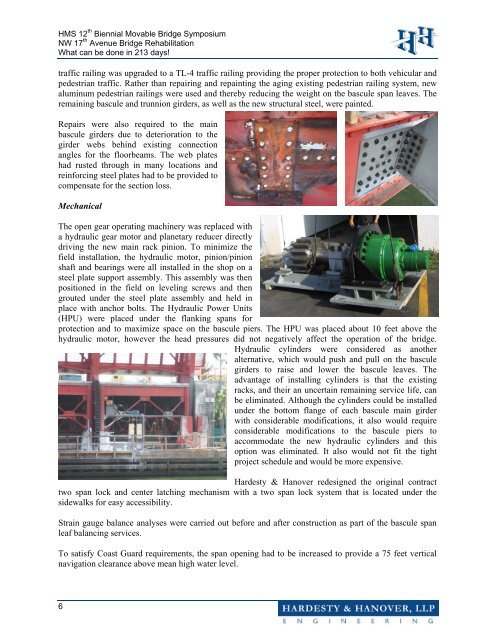

HMS 12 th Biennial Movable <strong>Bridge</strong> Symposium<strong>NW</strong> 17 th <strong>Avenue</strong> <strong>Bridge</strong> <strong>Rehabilitation</strong>What can be done in 213 days!traffic railing was upgraded to a TL-4 traffic railing providing <strong>the</strong> proper protection to both vehicular andpedestrian traffic. Ra<strong>the</strong>r than repairing and repainting <strong>the</strong> aging existing pedestrian railing system, newaluminum pedestrian railings were used and <strong>the</strong>reby reducing <strong>the</strong> weight on <strong>the</strong> bascule span leaves. Theremaining bascule and trunnion girders, as well as <strong>the</strong> new structural steel, were painted.Repairs were also required to <strong>the</strong> mainbascule girders due to deterioration to <strong>the</strong>girder webs behind existing connectionangles for <strong>the</strong> floorbeams. The web plateshad rusted through in many locations andreinforcing steel plates had to be provided tocompensate for <strong>the</strong> section loss.MechanicalThe open gear operating machinery was replaced witha hydraulic gear motor and planetary reducer directlydriving <strong>the</strong> new main rack pinion. To minimize <strong>the</strong>field installation, <strong>the</strong> hydraulic motor, pinion/pinionshaft and bearings were all installed in <strong>the</strong> shop on asteel plate support assembly. This assembly was <strong>the</strong>npositioned in <strong>the</strong> field on leveling screws and <strong>the</strong>ngrouted under <strong>the</strong> steel plate assembly and held inplace with anchor bolts. The Hydraulic Power Units(HPU) were placed under <strong>the</strong> flanking spans forprotection and to maximize space on <strong>the</strong> bascule piers. The HPU was placed about 10 feet above <strong>the</strong>hydraulic motor, however <strong>the</strong> head pressures did not negatively affect <strong>the</strong> operation of <strong>the</strong> bridge.Hydraulic cylinders were considered as ano<strong>the</strong>ralternative, which would push and pull on <strong>the</strong> basculegirders to raise and lower <strong>the</strong> bascule leaves. Theadvantage of installing cylinders is that <strong>the</strong> existingracks, and <strong>the</strong>ir an uncertain remaining service life, canbe eliminated. Although <strong>the</strong> cylinders could be installedunder <strong>the</strong> bottom flange of each bascule main girderwith considerable modifications, it also would requireconsiderable modifications to <strong>the</strong> bascule piers toaccommodate <strong>the</strong> new hydraulic cylinders and thisoption was eliminated. It also would not fit <strong>the</strong> tightproject schedule and would be more expensive.Hardesty & Hanover redesigned <strong>the</strong> original contracttwo span lock and center latching mechanism with a two span lock system that is located under <strong>the</strong>sidewalks for easy accessibility.Strain gauge balance analyses were carried out before and after construction as part of <strong>the</strong> bascule spanleaf balancing services.To satisfy Coast Guard requirements, <strong>the</strong> span opening had to be increased to provide a 75 feet verticalnavigation clearance above mean high water level.6