Sanitary Sewage Pump Stations - The City of Wentzville | Missouri

Sanitary Sewage Pump Stations - The City of Wentzville | Missouri

Sanitary Sewage Pump Stations - The City of Wentzville | Missouri

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

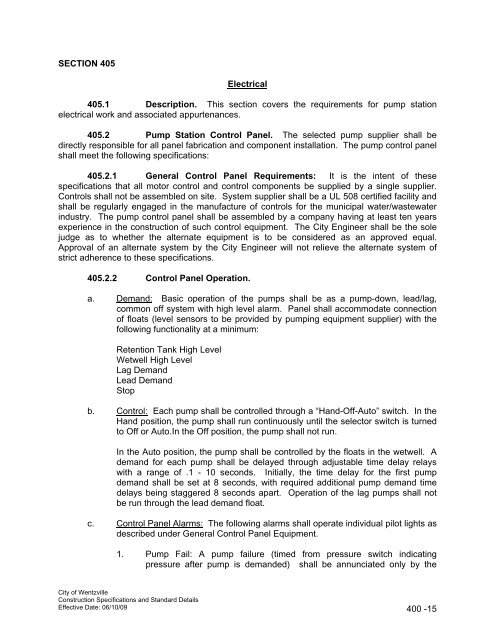

SECTION 405Electrical405.1 Description. This section covers the requirements for pump stationelectrical work and associated appurtenances.405.2 <strong>Pump</strong> Station Control Panel. <strong>The</strong> selected pump supplier shall bedirectly responsible for all panel fabrication and component installation. <strong>The</strong> pump control panelshall meet the following specifications:405.2.1 General Control Panel Requirements: It is the intent <strong>of</strong> thesespecifications that all motor control and control components be supplied by a single supplier.Controls shall not be assembled on site. System supplier shall be a UL 508 certified facility andshall be regularly engaged in the manufacture <strong>of</strong> controls for the municipal water/wastewaterindustry. <strong>The</strong> pump control panel shall be assembled by a company having at least ten yearsexperience in the construction <strong>of</strong> such control equipment. <strong>The</strong> <strong>City</strong> Engineer shall be the solejudge as to whether the alternate equipment is to be considered as an approved equal.Approval <strong>of</strong> an alternate system by the <strong>City</strong> Engineer will not relieve the alternate system <strong>of</strong>strict adherence to these specifications.405.2.2 Control Panel Operation.a. Demand: Basic operation <strong>of</strong> the pumps shall be as a pump-down, lead/lag,common <strong>of</strong>f system with high level alarm. Panel shall accommodate connection<strong>of</strong> floats (level sensors to be provided by pumping equipment supplier) with thefollowing functionality at a minimum:Retention Tank High LevelWetwell High LevelLag DemandLead DemandStopb. Control: Each pump shall be controlled through a “Hand-Off-Auto” switch. In theHand position, the pump shall run continuously until the selector switch is turnedto Off or Auto.In the Off position, the pump shall not run.In the Auto position, the pump shall be controlled by the floats in the wetwell. Ademand for each pump shall be delayed through adjustable time delay relayswith a range <strong>of</strong> .1 - 10 seconds. Initially, the time delay for the first pumpdemand shall be set at 8 seconds, with required additional pump demand timedelays being staggered 8 seconds apart. Operation <strong>of</strong> the lag pumps shall notbe run through the lead demand float.c. Control Panel Alarms: <strong>The</strong> following alarms shall operate individual pilot lights asdescribed under General Control Panel Equipment.1. <strong>Pump</strong> Fail: A pump failure (timed from pressure switch indicatingpressure after pump is demanded) shall be annunciated only by the<strong>City</strong> <strong>of</strong> <strong>Wentzville</strong>Construction Specifications and Standard DetailsEffective Date: 06/10/09 400 -15