Sucker Rod Sucker Rod Drive Rod - Alberta Oil Tool

Sucker Rod Sucker Rod Drive Rod - Alberta Oil Tool

Sucker Rod Sucker Rod Drive Rod - Alberta Oil Tool

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

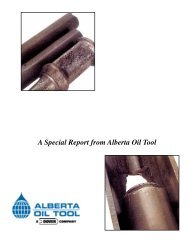

NORRIS DRIVE RODS ®Over the years, <strong>Alberta</strong> <strong>Oil</strong> <strong>Tool</strong> (AOT) has taken pride in being a world leader in innovation andmanufacturing excellence. Utilizing extensive research and development, AOT has taken the standard,age-old sucker rod designed for reciprocating application and modified it to be optimized for use withProgressing Cavity Pump (PCP) systems. AOT has made important improvements to the design toboth the rod and coupling resulting in a rod string that is far superior to any standard sucker rod string inPCP application.NORRIS DRIVE RODS ®Conventional sucker rods were originally designed for use with reciprocating beam pumps. They arevery well suited for this type of application and they perform this function effectively. The design of thesucker rod connection is sound for transmitting high axial, dynamic loads, and has withstood the test oftime by performing well with only minor changes over the past several decades. However, the advent ofthe Progressing Cavity Pump (PCP) has caused a shift in the thinking behind rod string connections. Ina PCP application, a connection is subjected to static axial loading as well as high torsional loading. Inthis type of loading scenario, the standard API sucker rod connection design is deficient. In response,AOT developed the <strong>Drive</strong> <strong>Rod</strong> ® with connections better suited to the type of stresses found in PCPapplications. The <strong>Drive</strong> <strong>Rod</strong> ® pin has a modified thread profile which is vastly superior with regards totorsional capacity. The improvement in pin strength also allowed for the <strong>Drive</strong> <strong>Rod</strong> ® pin to bedownsized. The benefits of downsizing the connection are enormous and include less flow restriction,decreased tubing wear and longer fatigue life. All of these gains are achieved while still providing astronger, more reliable connection between every rod in the string.<strong>Drive</strong> <strong>Rod</strong>®<strong>Sucker</strong> <strong>Rod</strong>

Having smaller connections in a rod string has several key benefits. The first benefit is less restrictionof flow through the tubing. The relatively small cross-sectional area of <strong>Drive</strong> <strong>Rod</strong> ® connections allowsfar more room for fluid to flow through.<strong>Drive</strong> <strong>Rod</strong> ® Size<strong>Sucker</strong> <strong>Rod</strong> ConnectionSizeAdditional Flow Areawhen using <strong>Drive</strong> <strong>Rod</strong>s ®1” w/ 7 / 8 ” pin 1” Slim-hole 28%1” w/ 7 / 8 ” pin 1” Regular 51%1- 1 / 4 ” w/ 1” pin 1- 1 / 8 ” Slim-Hole 27%1- 1 / 4 ” w/ 1” pin 1- 1 / 8 ” Regular 50%Additional Flow Area gained by using <strong>Drive</strong> <strong>Rod</strong>s ® in 3.5” tubing. <strong>Drive</strong> <strong>Rod</strong>s ®come standard with Slim-Hole couplings and are compared to sucker rodconnections with both Slim-Hole and Regular connections.This added flow area greatly reduces the pressure on the pump, which results in less stress beingapplied to the pump, the drive head and the rod string. The overall effect of lowering the flow restrictionis a longer service life for all components in the pumping system.

A second benefit of having downsized connections is the reduction of tubing wear. In any PCPapplication, tubing wear is a concern. <strong>Rod</strong>s rubbing on the tubing is inevitable and can eventually leadto tubing failure. Since <strong>Drive</strong> <strong>Rod</strong> ® connections have a downsized outside diameter, there is less of adifference between the outside diameter of the coupling and that of the rod body. The implication of thisis that more of the rod body contacts the tubing in between the connections. In essence, A <strong>Drive</strong> <strong>Rod</strong> ®has its’ rod/tubing contact forces spread over more of the rod body, rather than simply riding on theconnections alone.Perhaps the most important advantage of using <strong>Drive</strong> <strong>Rod</strong>s ® in a PCP application, is the extendedfatigue life associated with having downsized connections. In a PCP system, by far the most commoncause of failure is fatigue damage caused by well bore deviation. A steel rod which is caused to flexlaterally, even slightly , and then rotated, will experience extreme dynamic loading. Every time the rodstring makes one complete revolution, the bent section will be exposed to one stress cycle. To put thisin perspective, a rod string operating at 200rpm will be exposed to 1,000,000 stress cycles in just threeand a half days. Therefore, it is of utmost importance that the bending loads applied to a rod string beminimized.All wells have some degree of well bore deviation. Consequently, a rod string placed in any well mustbe able to flex laterally. A key point to consider is that the connections in the string are far stiffer thanthe rod bodies. The connections are larger in diameter than the corresponding rod bodies and,therefore, have a greater resistance to flexing. As a result, when bending loads are applied, theconnection tends to stay more rigid, and the rod body adjacent to the connection is made to flex more.This means that a great deal of stress is applied to the rod string just below the forged upset, where theflexible body meets the rigid connection.The fact that Norris <strong>Drive</strong> <strong>Rod</strong> ® connections are smaller than those of sucker rods, means that <strong>Drive</strong><strong>Rod</strong> ® connections are far less stiff laterally. More importantly, it means that the stiffness of the <strong>Drive</strong><strong>Rod</strong> ® connection is far closer to that of the <strong>Drive</strong> <strong>Rod</strong> ® body than is the case with sucker rods. Thedifference in the outer dimensions of a <strong>Drive</strong> <strong>Rod</strong> ® and a sucker rod connection is relatively large, andbeing that the relation between diameter and stiffness is exponential, the difference in stiffness betweenthe two is considerable. For example, a 1” coupling is four times more rigid than a 7 / 8 ” coupling. That isto say that if the same bending load is applied to both a 1” and a 7 / 8 ” coupling, the 7 / 8 ” coupling will flexfour times as much. The overall effect is that less stress is transferred to the rod body on either side ofthe connection, resulting in a dramatic improvement in fatigue life.

NORRIS HIGH STRENGTH COUPLINGSManufactured by AOT, Norris High Strength Couplings also differ from standard sucker rod couplings.Norris High Strength Couplings have unique raw material properties, contact-face dimensions andmanufacturing processes that make them an ideal choice for PCP applications.Norris High Strength Couplings are made from AISI 4130 heat-treated material and have a highermechanical strength than standard Class T couplings. Norris High Strength Couplings have a yieldstrength that is 30% greater than standard Class T couplings, making them well-suited for the highstressenvironment which are typical with PCP applications.MaterialYield Strength(PSI)Hardness(HRA)API Class T AISI 8630 80,000 min 56 - 62Norris HighStrengthAISI 4130 105,000 min 63 - 65The Norris High Strength Couplings that are used with Norris drive <strong>Rod</strong>s ® also have slightly differentdimensions with regards to the contact face. The contact face of the Norris coupling has been widenedin order to maximize the contact area between the rod shoulder and the coupling. The Norrisconnection contact area is more than 37% greater than the standard API connection. The result of thisis increased rod/coupling friction and ultimately, increased connection strength.Norris couplings are also unique in the way in which they are manufactured. First of all, all Norriscoupling threads are rolled rather than cut into the material. This means that no material is removedfrom the inside of the coupling, but instead material is cold-formed to produce threads. This processresuts in more steel fibers being pressed into the thread roots resulting in a much stronger threadprofile. It is extremely important that all Norris drive <strong>Rod</strong>s ® (which also have rolled threads) be fittedwith rolled-thread couplings. Mating a rolled-thread rod with a cut-thread coupling will inevitably lead tothread galling, an possible connection failure.In addition, Norris high Strength Coupling threads are subjected to a thread lubrication process knownas “Phosphating”. This process involves chemically adhering a Zinc-Phosphate coating to the interior ofthe coupling. The Zinc-Phosphate coating acts as a permanent thread lubricant which significantlyreduces the possibility of thread galling from occurring. After the coating is applied, the contact face ofthe coupling is machined so as to remove any trace of the Zinc-Phosphate coating. AOT takes greatcare to ensure that the coating is fully removed from the contact face in order to ensure that the frictionlock between the rod shoulder and the coupling is not compromised.

TESTINGAll of these unique characteristics of Norris <strong>Drive</strong> <strong>Rod</strong>s ® and High Strength Couplings combine to form astrong, dependable rod string intended specifically for PCP application. Destructive testing performedat CFER Technologies has verified the Norris <strong>Drive</strong> <strong>Rod</strong> ® connection is vastly superior to the standardsucker rod connection with regards to torsional strength.The following plots show typical results of the testing performed. The tests were performed using 1”Pins - both API sucker rod and Norris <strong>Drive</strong> <strong>Rod</strong> ® - with oversized bodies. This allowed for directcomparison of the strength of the connections alone. In all tests, the connections were made up usingNorris displacement cards, and then subjected to a 50,000 lb. axial load. While the axial load was heldconstant, a torque load was applied. The torque load was slowly increased until ultimate failureoccurred.

The below table clearly shows the Norris <strong>Drive</strong> <strong>Rod</strong> ® connection using Norris High Strength Couplingshas a torque capacity that is more than double that of the standard APU sucker rod connection. Itshould be stressed that these tests involved the connections only and not their associated rod bodies.Yield Torque (ft.lb.)Peak Torque (ft.lb.)API Norris API NorrisTest 1 1900 5100 3400 6599Test 2 1800 5300 2781 6756

SUMMARYNorris <strong>Drive</strong> <strong>Rod</strong>s ® have many features which differ from standard sucker rods. All of these differenceswere made with the intent of making the best possible rod string specifically for use with PCP systems.In addition, the quality of these products is highly controlled. Dimensional inspection is performed on100% of Norris <strong>Drive</strong> <strong>Rod</strong>s® and Norris High Strength Couplings produced at AOT. Because of this,the Norris <strong>Drive</strong> <strong>Rod</strong> ® string is second to none in the industry with regards to strength and durability inPCP applications.This being said, the strength of a rod string is only as high as its weakest link. Norris rods should not beused in conjunction with another manufacturers’ couplings or rods. Norris Couplings are specificallydesigned to be used with Norris rods. The type of thread and the dimensional tolerances are verydifferent from that of other manufacturers. For this reason, rod strings combining Norris <strong>Drive</strong> <strong>Rod</strong>s®with another manufacturers’ couplings are at risk of having a very poor run life and torque performance.

norrisrods.comTulsa, OklahomaP: (800) 767-7637albertaoiltool.comEdmonton, <strong>Alberta</strong>P: (780) 434-8566© DAL - Norris/AOT 05/2014