22 11 23-01-001 Patterson Split Case - Garney Construction

22 11 23-01-001 Patterson Split Case - Garney Construction

22 11 23-01-001 Patterson Split Case - Garney Construction

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

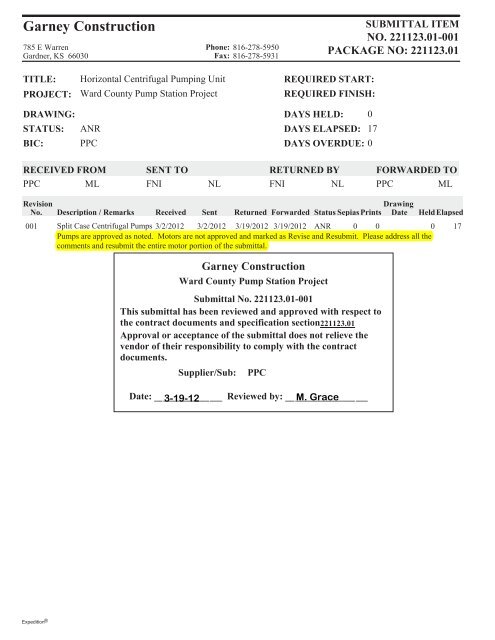

<strong>Garney</strong> <strong>Construction</strong>785 E WarrenGardner, KS 66030Phone: 816-278-5950Fax: 816-278-5931SUBMITTAL ITEMO. <strong>22</strong><strong>11</strong><strong>23</strong>.<strong>01</strong>-0<strong>01</strong>PACKAGE O: <strong>22</strong><strong>11</strong><strong>23</strong>.<strong>01</strong>TITLE:PROJECT:DRAWIG:STATUS:BIC:Horizontal Centrifugal Pumping UnitWard County Pump Station ProjectANRPPCREQUIRED START:REQUIRED FIISH:DAYS HELD: 0DAYS ELAPSED: 17DAYS OVERDUE: 0RECEIVED FROMPPC MLSET TOFNINLRETURED BYFNI NLFORWARDED TOPPC MLRevisiono.Description / RemarksReceivedSentDrawingReturned Forwarded Status Sepias Prints Date HeldElapsed0<strong>01</strong> <strong>Split</strong> <strong>Case</strong> Centrifugal Pumps 3/2/2<strong>01</strong>2 3/2/2<strong>01</strong>2 3/19/2<strong>01</strong>2 3/19/2<strong>01</strong>2 ANR 0 0 0 17Pumps are approved as noted. Motors are not approved and marked as Revise and Resubmit. Please address all thecomments and resubmit the entire motor portion of the submittal.<strong>Garney</strong> <strong>Construction</strong>Ward County Pump Station ProjectSubmittal o. <strong>22</strong><strong>11</strong><strong>23</strong>.<strong>01</strong>-0<strong>01</strong>This submittal has been reviewed and approved with respect tothe contract documents and specification section<strong>22</strong><strong>11</strong><strong>23</strong>.<strong>01</strong>Approval or acceptance of the submittal does not relieve thevendor of their responsibility to comply with the contractdocuments.Supplier/Sub: PPCDate: ______________ 3-19-12 Reviewed by: _________________M. GraceExpedition ®

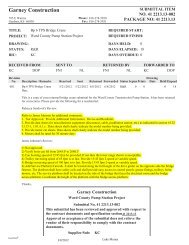

SUBMITTALShttps://projectdox.freese.com/imarkupwg/form.asp?formid=6315&wfdirect=&debug=&co...Page 1 of <strong>23</strong>/19/2<strong>01</strong>2Project No:Project:Client:Contractor:CMD<strong>11</strong>269ACMAR Ward County Transmission System - PumpsColorado River Municipal Water District<strong>Garney</strong>Shop Drawing #003Horizontal Centrifugal Pumping UnitsSUBMITTAL INFORMATIONSUBMITTALTYPE:SUBMITTAL #: CONTRACTOR REF #: SPEC SECTION: PLAN SHEET: SUBMITTAL STATUS:ShopDrawing003<strong>22</strong> <strong>11</strong> <strong>23</strong>.<strong>01</strong>-0<strong>01</strong><strong>22</strong> <strong>11</strong> <strong>23</strong>.<strong>01</strong> PendingSUBMITTALDESCRIPTION:Horizontal Centrifugal Pumping UnitsUPLOAD SUPPORTING DOCUMENTS<strong>22</strong> <strong>11</strong> <strong>23</strong>-<strong>01</strong>-0<strong>01</strong>.pdf 3/2/2<strong>01</strong>2 12:<strong>23</strong> PM Marcus GraceCONTRACTOR CERTIFICATIONCONTRACTOR COMMENTS:Please find Horizontal Centrifugal Pumps for review and approvalHOW WILL THE COPIES BE SUBMITTED:ElectronicNUMBER OF COPIES SUBMITTED: 1This shop drawing has been reviewed by the Contractor and certified to be in strict conformance with the Contract Documents as modified by addenda, field orders, andchange orders. Deviations can only be approved by field order or change order. Approval is only for conformance with the design concept of the project and compliancewith the intent of the information given in the Contract Documents. Contractor is responsible for dimensions to be confirmed and correlated at the job site; for informationthat pertains solely to the fabrication processes or to techniques of construction; and for the work of all trades.SUBMITTED BY: Marcus GraceDATE: 3/2/2<strong>01</strong>2 12:<strong>23</strong> PMREVIEWER COMMENTSREVIEWER NAME: REVIEWER EMAIL: COMPANY / ORGANIZATION DATESENT:DATECOMPLETED:Bryan Jannbcj@freese.comFreese & Nichols, Inc.3/2/2<strong>01</strong><strong>23</strong>/12/2<strong>01</strong>2REVIEWERCOMMENTS:Pumps are Approved as Noted, Motor is not approved per Jeff Hensley comments:1. See Pump Comments from Jeff Hensley.2. Clarification: Regarding operating condition No. 2, the submittal states that the <strong>Patterson</strong>pump will overshoot this point and will hit 9.750 GPM at 130'. This operating condition is anacceptable replacement of what was specified for the secondary operating point. It also statesthat <strong>11</strong>,500 GPM at 100' is outside the AOR. Operating at this condition (<strong>11</strong>,500, 100') will not benecessary and therefore it is not the intent to operate this pump outside the AOR.3. <strong>Garney</strong> (CMAR) shall coordinate with the pump manufacturer and contractor for supply ofthe leveling shims. The specs call for those to be provided by the pump manufacturer and thesubmittal notes these are to be provided by the Contractor.REVIEWER NAME: REVIEWER EMAIL: COMPANY / ORGANIZATION DATESENT:DATECOMPLETED:JamesJohnsonjkj@freese.comFreese and Nichols Inc. 3/2/2<strong>01</strong><strong>23</strong>/2/2<strong>01</strong>2REVIEWERCOMMENTS:No commentsREVIEWER NAME: REVIEWER EMAIL: COMPANY / ORGANIZATION DATESENT:DATECOMPLETED:Jeff Hensleyjnh@freese.com4055 International Plaza3/2/2<strong>01</strong><strong>23</strong>/<strong>11</strong>/2<strong>01</strong>2

SUBMITTALShttps://projectdox.freese.com/imarkupwg/form.asp?formid=6315&wfdirect=&debug=&co...Page 2 of <strong>23</strong>/19/2<strong>01</strong>2REVIEWERCOMMENTS:See attached review comments.Pumps - Approved as Noted. Additional information required.Motors - Not Approved, revise and re-submit. Provide complete re-submittal.REVIEWER NAME: REVIEWER EMAIL: COMPANY / ORGANIZATION DATESENT:RebeccaSandovalrs@freese.comFreese and Nichols, Inc3/2/2<strong>01</strong>2DATECOMPLETED:3/17/2<strong>01</strong>2REVIEWERCOMMENTS:3/17/2<strong>01</strong>2Refer to Jeff Hensley and Bryann Jann for additional comments.1.The motor nameplate shall include information on the NEMA design and the nominalefficiency. Currently these fileds are left blank on both the motor nameplate and the MotorSubmittal Data Sheet.UPLOAD SUPPORTING REVIEW DOCUMENTSJNH _ PUMP & MOTOR REVIEW COMMENTS.pdfRemove 3/<strong>11</strong>/2<strong>01</strong>2 2:30 PM Jeff HensleyDISPLAY ROUTING SLIPCurrent Workflow Step: DCS Admin: Debby Greer Workflow Initiator: Marcus Grace(Click on the Names above to Email User)FNI Forms v1.04

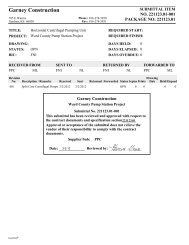

<strong>Garney</strong> <strong>Construction</strong>785 E WarrenGardner, KS 66030Phone: 816-278-5950Fax: 816-278-5931SUBMITTAL ITEMNO. <strong>22</strong><strong>11</strong><strong>23</strong>.<strong>01</strong>-0<strong>01</strong>PACKAGE NO: <strong>22</strong><strong>11</strong><strong>23</strong>.<strong>01</strong>TITLE:PROJECT:DRAWING:STATUS:BIC:Horizontal Centrifugal Pumping UnitWard County Pump Station ProjectOPNFNIREQUIRED START:REQUIRED FINISH:DAYS HELD: 0DAYS ELAPSED: 0DAYS OVERDUE: 0RECEIVED FROMPPC MLSENT TOFNINLRETURNED BYFNI NLFORWARDED TOPPC MLRevisionNo.Description / RemarksReceivedSentDrawingReturned Forwarded Status Sepias Prints Date HeldElapsed0<strong>01</strong> <strong>Split</strong> <strong>Case</strong> Centrifugal Pumps 3/2/2<strong>01</strong>2 3/2/2<strong>01</strong>2 OPN 0 0 0 0<strong>Garney</strong> <strong>Construction</strong>Ward County Pump Station ProjectSubmittal No. <strong>22</strong><strong>11</strong><strong>23</strong>.<strong>01</strong>-0<strong>01</strong>This submittal has been reviewed and approved with respect tothe contract documents and specification section<strong>22</strong><strong>11</strong><strong>23</strong>.<strong>01</strong>Approval or acceptance of the submittal does not relieve thevendor of their responsibility to comply with the contractdocuments.Supplier/Sub:PPCDate: ______________ 3-2-12 Reviewed by: _________________Expedition ®

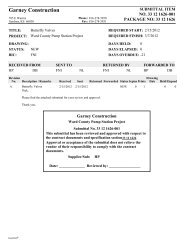

SUBMITTALFORWELL FIELD PUMP STATIONBLOCK F SECTION 59 WARD COUNTYWICKETT, TX 79756PUMPING UNITS WPS-P1, P2, P3SPECIFICATION SECTION <strong>22</strong> <strong>11</strong> <strong>23</strong>.<strong>01</strong>HORIZONTAL CENTRIFUGAL PUMPING UNITSPATTERSON ORDER NUMBER: SC-C<strong>01</strong>09398PATTERSON MODEL: 18”x 14” MABHORIZONTAL SPLIT CASEGARNEY CONSTRUCTION785 E. WARREN ST.GARDNER, KS 66030-1629

TABLE OF CONTENTSATTACHMENT AATTACHMENT BSECTION 1 GENERAL DATASTATEMENTS/CLARIFICATIONS & EXCEPTIONSREFERENCE LISTSCHEDULESECTION 2 PUMP DATA & DRAWINGSENGINEERING DATABEARING TEMPERATURE CALCULATIONSSPEED TORQUE CURVEMATERIAL LISTROTATIONAL VIEWSOUTLINE DIMENSIONS DRAWINGPUMP ASSEMBLY DRAWINGNAMEPLATE DRAWINGANCHOR BOLTS DRAWINGPIPING ARRANGEMENT DRAWINGSECTION 3 MOTORSECTION 4 COUPLINGSECTION 5 PUMP ACCESSORIESCONAX RTD’SRTD JUNCTION BOXWIRING DIAGRAMELECTRIC CONDUIT LAYOUT DRAWINGSECTION 6 PUMP PERFORMANCE TEST AND HYDROSTATIC TESTSECTION 7 PUMP PERFORMANCE DATASECTION 8 PUMP PAINTINGSECTION 9 SPARE PARTS AND OTHER ACCESSORIES/EQUIPMENT LIST

ATTACHMENT ASUBMITTAL DATA SHEETHORIZONTAL CENTRIFUGAL PUMPING UNITS AND MOTORS FOR:WELL FIELD PUMP STATIONSubmit the following data with Proposal for each size of Pumping Unit:Pump Data Pumps WPS P1, WPS P2,& WPS P 31. Manufacturer2. Rated speed3. Impeller Diameter and Material4. Shut off Head5. Specific Speed6. Maximum Brake Horsepower Requirements of Pump7. Efficiency at BEP8. NPSH Required at Rated Head9. NPSH Required at Minimum Head for Rated DesignPoint <strong>11</strong>0. Wire to water efficiency at 20,833 GPM and 179 feetTDHWeight1. Weight of Pump2. Weight of Motor3. Total Weight of Pump, Motor, and FramePumps WPS P1, WPSP2, & WPS P 3Note: Also attach or enclose with the Proposal additional description of all equipment offered asrequested in the equipment specifications, including but not limited to the physical dimensions,performance, characteristic curves and pertinent engineering data to permit easy review and evaluationby the Engineer and Buyer.Horizontal Centrifugal Pumping Units <strong>22</strong> <strong>11</strong> <strong>23</strong>.<strong>01</strong> 19CMD<strong>11</strong>269 Contract C 1 Pumping Units and Motors10/06/<strong>11</strong>

ATTACHMENT BMOTOR SUBMITTAL DATA SHEET - HORIZONTAL CENTRIFUGAL PUMPING UNITSSubmit the following data with shop drawing submittal for each size and type of Motor:ManufacturerFrameTypeVoltageStarting MethodShaft SizeInsulation ClassSIEMENS50<strong>11</strong>SSQUIRREL CAGE460SOFT-STARTF-VPIMotor HPEnclosureRPMPhaseHertzDuty400TEFC<strong>11</strong>83360CONTINUOUSFull Load AmpsLocked Rotor AmpsLocked Rotor TorqueLocked Rotor kVA/HP4872807<strong>22</strong>91 lb-ft5.59No Load AmpsLocked Rotor Torque% Breakdown TorqueRotor WK2 (lb-ft2)180.6129% FLT<strong>22</strong>6% FLT205NEMA DesignService FactorInrush Current (% of Full Load)Number of Safe Starts Per Day-1.155765,000 STARTS LIFETIME, FOLLOW GIVEN STARTING DUTY*Full Load Temp Rise, in Degree Celsius over 50 Celsius Ambient (at 1.0 S.F.)*Service Factor Temp Rise, in Degree Celsius over 50 Celsius Ambient (at 1.15 S.F.)80 DEG C BY DET90 DEG C BY DET*Limiting Temperature RiseResistance (at 25 o C):Bearings: Type/Size0.00655 OHMSLife Lubrication:Exhaust Air (CFM) Exhaust Air Temp Rise ( o F)1.15 S.F. Load4/4 Load3/4 Load2/4 Load1/4 LoadEfficiency Power Factor Current94.1 82.2 55794.4 81.4 48794.8 77.8 38194.5 68.7 28892.1 46.5 219RTD Types and MountingRTD Alarm and Trip Set PointMotor Sound Power LevelMotor Recommended Power FactorSpace Heater VoltageSTATOR: 100 OHM PLATINUM, EMBEDDEDSTATOR: ALARM = 155C, TRIP = 170C80dBA @ 3ft, UNLOADEDFOR 95% PF: 1<strong>22</strong>kVAR120/240 Wattage525Horizontal Centrifugal Pumping Units <strong>22</strong> <strong>11</strong> <strong>23</strong>.<strong>01</strong>-20CMD<strong>11</strong>269 - Contract C-1 - Pumping Units and Motors10/06/<strong>11</strong>

STATEMENTS, CLARIFICATIONS & EXCEPTIONS1. <strong>Patterson</strong> has over 10 years’ experience in the design, manufacture andapplication of pumping units of the type, size, and performance as specified.2. Pumps will be tested in accordance with Hydraulic Institute standards.Requirements of <strong>22</strong> <strong>11</strong> <strong>23</strong>.<strong>01</strong>/1.03 B will also be met.3. Material certification for case and impeller castings and for coupons cast oneach pour of metal will be provided as required by <strong>22</strong> <strong>11</strong> <strong>23</strong>.<strong>01</strong>/1.3 B1-a.4. The submitted coupling FASTS GEAR is a self-aligning coupling. This typecoupling does not exclude the alignment requirement between pump andmotor.5. All bolts and nuts will be stainless steel per Specs however items <strong>22</strong> and 69are SKF standard locknut and lock washers and are made of Steel per SKFStandards.6. Pump coating will meet requirements of <strong>22</strong> <strong>11</strong> <strong>23</strong>.<strong>01</strong>/2.<strong>01</strong> K – Addendum 1.Drawing G-3 NOTE 8 reference section we do not have and we cannotconfirm compliance.7. Pump is rated for outdoor installation and operation, but is not provided withany equipment for protection against freezing. This is to be provided byothers.8. When 2 pumps will operate in parallel at full speed the operating point forindividual pump is within AOR and will operate without cavitation even atminimum water level in suction tank. (Elevation as stated in <strong>22</strong> <strong>11</strong> <strong>23</strong>.<strong>01</strong>/1.03B.) This confirms compliance with requirements of <strong>22</strong> <strong>11</strong> <strong>23</strong>.<strong>01</strong>-8/ 1.07-7b.9. Pump, motor and coupling guard will be assembled to the pump base andaligned prior to shipment. However it is highly recommended to recheckcoupling alignment and adjust if needed prior to start up.10. Pump and motor are designed to withstand without any damage to areversed rotation of 140 percent of normal operating speed or at themaximum speed due to a reverse flow at maximum discharge head.<strong>11</strong>. Pump is capable to operate up to one minute at shut off.

12. All the three pumps WPS-P1,-P2,-P3 are identical units and will have thesame impeller trim.13. Impeller will be finished smooth all over and is designed of ample strengthand stiffness for maintaining the maximum capacity of the unit.14. Impeller will be statically and dynamically balanced before to be assembled.15. Pump bearings are designed to carry the axial and radial thrust loads withoutthe addition of external cooling. Bearing L10 life will exceed 100,000hrs atthe rated head and flow.16. Pump base will be stress relieved before machining.17. Interior of casing will be smooth and free of surface defects.18. CLARIFICATION SECTION <strong>22</strong> <strong>11</strong> <strong>23</strong>.<strong>01</strong> /2.<strong>01</strong>D- <strong>Case</strong> rings are clampedbetween upper and lower case and are secured with anti- rotation stainlesssteel dowel pins.19. CLARIFICATION SECTION <strong>22</strong> <strong>11</strong> <strong>23</strong>.<strong>01</strong> /2.<strong>01</strong>F- Pressure regulating valvesand gauges are not needed for pumps with a self-flush system and packing.Pumps will be equipped with <strong>Patterson</strong> standard system for split casepumps. The piping will be insulated to operate in freezing conditions.20. CLARIFICATION SECTION <strong>22</strong> <strong>11</strong> <strong>23</strong>.<strong>01</strong> /2.<strong>01</strong>J-Pump and motor will bemounted on accurately machined pads. <strong>Patterson</strong> standard stainless steelshims will be provided for motor alignment.21. CLARIFICATION SECTION <strong>22</strong> <strong>11</strong> <strong>23</strong>.<strong>01</strong>/1.07.A.7 – As shown in the pumpcurves included in the proposal, the pump shall overshoot Point 2. Based onthe system curves included in the contract documents the expectedoperating condition of one pump against the Existing Luminant Line is 9,750GPM at 130 ft. Pump has the capacity to operate at 100 ft. of head providing<strong>11</strong>500 GPM. But this will require NPSHA (available) to exceed 27.4 FT.NOTE:The 100FT/<strong>11</strong>500GPM operating point is located outside pumpallowable operating range.<strong>22</strong>. CLARIFICATION SECTION <strong>22</strong> <strong>11</strong> <strong>23</strong>.<strong>01</strong>/1.03.3C – Leveling shims for baseto be provided by Contractor.<strong>23</strong>. CLARIFICATION SECTION <strong>22</strong> <strong>11</strong> <strong>23</strong>.<strong>01</strong>/3.<strong>01</strong>K – Pump top coat paint willhave a custom blue color to match paint chips provided by customer.24. CLARIFICATION SECTION <strong>22</strong> <strong>11</strong> <strong>23</strong>.<strong>01</strong>/1.<strong>01</strong>B and 2.<strong>01</strong>F – Pump thermalfreeze protection system to be done by Contractor.

25. CLARIFICATION SECTION <strong>22</strong> <strong>11</strong> <strong>23</strong>.<strong>01</strong>/1.03B.1.a – <strong>Patterson</strong> does nothave the capability to test pump at flows exceeding 10600 GPM.26. CLARIFICATION: A 4” NPT ARV port will be provided on top of the case asshown in drawings P-2 and P-8. The 4” ARV is to be provided by others.27. CLARIFICATION: Note 2 on drawing P-3 requires bolts and nuts to be 304S.S. Bolts made of 304 S.S. will not provide sufficient strength. <strong>Patterson</strong> willprovide hardware made of 316 S.S.28. CLARIFICATION SECTION <strong>22</strong> <strong>11</strong> <strong>23</strong>.<strong>01</strong>/2.<strong>01</strong> G – Oil lubrication of bearingsis inadequate to pump operating conditions. Pump bearing will be greaselubricated. See recommendation from SKF (Attached).

ABBREVIATED LIST OF SPLIT CASEPUMP INSTALLATIONSOwner: The City of Wichita Water & Sewer DepartmentAddress: 1815 W. Pine, Wichita, KS 67203Contact: Mr. Jerry Blain - Superintendent Production and pumping @ 316-269-4764Project/Location: Hess Pump Station, Wichita, KansasYear of Installation: 1997S/N QTY MODEL FLUID GPM TDH HP RPMC006933-<strong>01</strong>-03 3 30 X 24 MAA Raw/Fin. Water 20,000 300 1980 900C006933-04 1 30 X 24 MAA Raw/Fin. Water 20,000 302 1980 880C006933-05 1 30 X 24 MAA Raw/Fin. Water 17,500 264 1980 900Owner: The City of Wichita Water & Sewer DepartmentAddress: 1815 W. Pine, Wichita, KS 67203Contact: Mr. Jerry Blain - Superintendent Production and pumping @ 316-269-4764Project/Location: Cheyney Pump Station, Wichita, KansasYear of Installation: 1995 & 1997S/N QTY MODEL FLUID GPM TDH HP RPMC004307 2 30 X 24 MAA Raw/Fin. Water 14,000 200 1000 705C0<strong>01</strong>454 2 30 X 24 MAA Raw/Fin. Water 20,600 264 1980 900Owner: City of Dalton, GeorgiaAddress: PO Box 869, Dalton, GA 307<strong>22</strong>-0869Contact: Public Works Department @ 706 278-7077Project/Location: Loopers Bend Water Reclamation Facility, Dalton, GAYear of Installation: 1999 & 2000S/N QTY MODEL FLUID GPM TDH HP RPMC<strong>01</strong>3765 4 24 x 16 MAAS Treated Effluent 12,000 219 800 880C0<strong>22</strong>564 2 24 x 16 MAAS Treated Effluent 12,000 <strong>22</strong>0 800 880C0<strong>22</strong>565 2 12 x 8 MAA Raw/Fin. Water 3,000 215 200 <strong>11</strong>80Owner: Gwinnett County, GeorgiaAddress: 684 Winder Highway, Lawrenceville, GA 30045Contact: Mr. Reza Baniassad, Water Production Engineer @ 770-904-3202Project/Location: Lanier Water Treatment PlantYear of Installation: 20<strong>01</strong>, 2003 & 2007S/N QTY MODEL FLUID GPM TDH HP RPMC003310 4 36 x 30 MAA Raw/Fin. Water 35,415 129 1500 590C0033<strong>11</strong> 3 20 x 18 MAA Raw/Fin. Water 10,070 159 500 590C053404 3 30 X 24 MAA Raw/Fin. Water 17,500 <strong>22</strong>0 1500 705

Owner: Gwinnett County, GeorgiaAddress: 684 Winder Highway, Lawrenceville, GA 30045Contact: Mr. Reza Baniassad, Water Production Engineer @ 770-904-3202Project/Location: Shoal Creek Pump StationYear of Installation: 20<strong>01</strong>S/N QTY MODEL FLUID GPM TDH HP RPMC031313 3 36 x 30 MAA Raw/Fin. Water 35,000 260 3000 710C031314 2 30 X 24 MAA Raw/Fin. Water 2,000 260 1500 710C031315 2 24 x 20 MAD Raw/Fin. Water 6,000 24 60 590C031316 2 30 X 24 MAA Raw/Fin. Water 18,900 47 300 590C031317 3 8 x 6 MI Raw/Fin. Water 1,920 <strong>11</strong>7 75 1780C031318 2 5 x 4 x 12 SSc Raw/Fin. Water 560 100 25 1780C031319 2 8 x 6 MI Raw/Fin. Water 1,600 120 75 1780Owner: North Texas Municipal Water AuthorityAddress: PO Box 2408, Wylie, TX 75098Contact: Administrative Offices @ 972-442-5405Project/Location: Water System Improvements, Wylie, TXYear of Installation: 20<strong>01</strong>S/N QTY MODEL FLUID GPM TDH HP RPMC027921 4 24 x 16 MAAS Raw/Fin. Water 14,560 350 1500 <strong>11</strong>80Owner: Tampa Bay WaterAddress: 2575 Enterprise Road, Clearwater, FL 33763Contact: Richard Girdley, Project Manager @ 813-470-4005Project/Location: Regional Water Treatment Plant, roundwater Treatment, HighService Pumping and Ground Storage Facilities, Hillsborough County, FLYear of Installation: 2002S/N QTY MODEL FLUID GPM TDH HP RPMC026985 5 24 x 16 MAASH Raw/Fin. Water 16,310 389 2000 <strong>11</strong>80C026986 1 18 x 14 MABH Raw/Fin. Water 16,310 389 600 <strong>11</strong>80Owner: Cobb County-Marietta Water AuthorityAddress: 1660 Barnes Mill Road, Marietta, GA 30062-7535Contact: Authority’s Main Office @ (770) 426-8788Project/Location: James E. Quarles Water Treatment Plant, Marietta, GAYear of Installation: 2002S/N QTY MODEL FLUID GPM TDH HP RPMC029197 2 42 x 36 MAD Raw/Fin. Water 31,944 38 800 505C029198 2 36 x 30 MAD Raw/Fin. Water 20,833 37 600 442C029199 2 30 x 24 MAD Raw/Fin. Water 16,000 39 350 590C029200 2 24 x 16 MAA Raw/Fin. Water 17,361 325 <strong>22</strong>50 <strong>11</strong>80C0292<strong>01</strong> 1 24 x 20 MAD Raw/Fin. Water 12,145 50 250 880

Owner: Erie City Water AuthorityAddress: 340 West Bayfront Parkway, Erie, PA 16507-2004Contact: John Presogna, Manager Water Quality @ 814-870-8000Project/Location: Chestnut Street Pump Station, Erie, PAYear of Installation: 2002S/N QTY MODEL FLUID GPM TDH HP RPMC029020 3 24 x 16 MAAS Raw/Fin. Water 12,500 267 1000 880Owner: Atlanta-Fulton County Water Resources CommissionAddress: 40 Courtland Street NE, Altanta, GA 30303Contact: Plant Administration Office @ 678-942-2790Project/Location: Atlanta-Fulton County Water Treatment Improvements Phase 2.5Year of Installation: 2003S/N QTY MODEL FLUID GPM TDH HP RPMC038451 6 24 x 16 MAA Raw/Fin. Water 17,<strong>22</strong>5 427 2500 <strong>11</strong>80Owner: City of Fort Worth, TexasAddress: Water Department, PO Box 870, Ft. Worth, TX 761<strong>01</strong>Contact: Seiavash Mir, Project Manager @ 817-392-8404Project/Location: Northside Pump Station and Ground Storage Res., Fort Worth, TXYear of Installation: 2004S/N QTY MODEL FLUID GPM TDH HP RPMC040675 2 18 x 14 MAB Raw/Fin. Water 9000 200 600 <strong>11</strong>80C040676 1 24 x 16 MAAS Raw/Fin. Water 8300 240 1000 880

WELL FIELD PUMP STATION, PUMPS WPS‐P1, P2, P3<strong>Patterson</strong> Order Number C<strong>01</strong>09398ID Task Name Start Finish <strong>11</strong> Qtr 1, 2<strong>01</strong>2 Qtr 2, 2<strong>01</strong>2 Qtr 3, 2<strong>01</strong>2Nov Dec Jan Feb Mar Apr May Jun Jul Aug Sep1 Order Accepted Thu 12/8/<strong>11</strong> Thu 12/8/<strong>11</strong>12/82 Pre‐Submittal Preparation & Review Thu 12/8/<strong>11</strong> Thu 1/5/1<strong>23</strong> Pre‐Submittal Conference Fri 1/6/12 Fri 1/6/124 Submittal Preparation Mon 1/9/12 Fri 3/2/125 Engineer Submittal Review Mon 3/5/12 Fri 3/16/126 Submittal Approval & Release to Manufacture Fri 3/16/12 Fri 3/16/127 Major Material Deliveries Mon 3/19/12 Tue 7/17/128 Castings Delivery Mon 3/19/12 Mon 4/30/129 Motor Delivery Mon 3/19/12 Tue 7/17/1210 Finalize/Issue Fabrication & Assembly Drawing Mon 3/19/12 Mon 4/<strong>23</strong>/12<strong>11</strong> Fabrication Set Up & Forming Tue 5/1/12 Tue 6/5/1212 Machining Wed 6/6/12 Tue 7/10/1213 Pump 1 Wed 7/<strong>11</strong>/12 Mon 7/<strong>23</strong>/1214 Assembly Wed 7/<strong>11</strong>/12 Tue 7/17/1215 Performance Pre‐Test Wed 7/18/12 Wed 7/18/1216 Impeller Adjustments Thu 7/19/12 Mon 7/<strong>23</strong>/1217 Pump 2 Tue 7/24/12 Mon 7/30/1218 Assembly Tue 7/24/12 Mon 7/30/1219 Pump 3 Tue 7/31/12 Mon 8/6/1<strong>22</strong>0 Assembly Tue 7/31/12 Mon 8/6/1<strong>22</strong>1 Hydrostatic Test Tue 8/7/12 Thu 8/9/1<strong>22</strong>2 Mount Motors Fri 8/10/12 Tue 8/14/1<strong>22</strong>3 Performance Testing Wed 8/15/12 Fri 8/17/1<strong>22</strong>4 Paint Mon 8/20/12 Fri 8/24/1<strong>22</strong>5 Quality Inspection Mon 8/27/12 Mon 8/27/1<strong>22</strong>6 Prep for Shipment Tue 8/28/12 Wed 8/29/1<strong>22</strong>7 Shipment Wed 8/29/12 Wed 8/29/1<strong>23</strong>/168/29TaskExternal MilestoneManual Summary Rollup<strong>Split</strong>Inactive TaskManual SummaryDate: Fri 3/2/12MilestoneSummaryInactive MilestoneInactive SummaryStart‐onlyFinish‐onlyProject SummaryManual TaskDeadlineExternal TasksDuration‐onlyProgress

PUMP ENGINEERING DATAPUMP SERIAL NUMBER: SC-C<strong>01</strong>09398 -<strong>01</strong>, -02, -03PUMP TAG #: WPS-P1, -P2, -P3PUMP PATTERSON MODEL:DIRECTION OF ROTATION:(AS SEEN FROM DRIVER END)18”x14” MAB HORIZONTAL SPLIT CASECWBARE PUMP WEIGHT: 7200 LBSPRIMARY OPERATING POINT #1: 6944 GPM179 FT<strong>11</strong>80 RPM357 BHP89.0 % EFFICIENCY17.8 FT NPSHRPRIMARY OPERATING POINT #2:MINIMUM ALLOWABLE FLOW:<strong>11</strong>500 GPM100 FT<strong>11</strong>80 RPM389 BHP70.9 % EFFICIENCY27.38 FT NPSHR2792 GPM @ <strong>11</strong>80 RPMMAXIMUM ALLOWABLE FLOW:10,767 GPM @ <strong>11</strong>80 RPMPUMP CASE DATA:HYDROSTATIC TEST: 135 PSISUCTION FLANGE SIZE: 18” - #125DISCHARGE FLANGE SIZE: 14” - #125WALL THICKNESS: 0.75”VENT /PRIMING NPT:ARV PORT:GAUGE NPT:DRAIN NPT:1.5” (STANDARD)4” NPT0.25” (STANDARD)0.75” (STANDARD)STUFFING BOX DATA:SLEEVE O.D.: 4 ½”

PAGE 2 - PUMP ENGINEERING DATA CONTINUEDPACKING BOX BORE: 5 9/16”PACKING BOX DEPTH: 4 7/8”BOX INLET NPT: ¼”PACKING SIZE: 1/2”NUMBER OF PACKING RINGS: 7WATER SEAL RING WIDTH: 1”IMPELLER DATA:PATTERN NUMBER: C-5762MAX DIAMETER: <strong>23</strong>.5”MIN DIAMETER: 20.5”PROVIDED DIAMETER:21.185” (estimated)MAXIMUM SPHERE: 2.125”NUMBER OF VANES: 7EYE AREA:131 sq. inchWEIGHT: 321WR^2 (MAX DIAMETER):165.7 lbs-ft^2WEAR RING CLEARANCE: 0.<strong>01</strong>6”PUMP SHAFT DATA:DIAMETER AT COUPLING: 3 3/16”DIAMETER AT IMPELLER: 3.75”DIAMETER UNDER SLEEVE: 3.75”BEARINGS SPAN: 48.75”COUPLING KEYWAY: ¾”x 3/8”IMPELLER KEYWAY: ¾”x 3/8”INBOARD BEARING:OUTBOARD BEARING:BEARING LUBRICATION:SKF 5217 DOUBLE ROW DEEP GROOVESKF 7314 BECBY ANGULAR CONTACTBACK TO BACKGREASE

PAGE 3 - PUMP ENGINEERING DATA CONTINUEDMOTOR:SIEMENS 400 HP, <strong>11</strong>80 RPM HORIZONTAL3 PHASE/ 60 CYCLE/ 460 VFRAME: 50<strong>11</strong>SY TEFCNEMA PREMIUM EFFICIENCYINVERTER DUTYCOUPLING:KOP FLEX FAST’SSIZE 4.5S.F. =1.5PUMP ACCESSORIES:1) BEARING RTDs (2/PUMP)CONNAX MODEL RTD 43100 OHM PLATINUM3 LEADPROXIMITY CUT TO LENGTH PROBECAST IRON HOUSING – NEMA 4 MODEL T5CISEALEDRTD TEMPERATURE SETTINGS:ALARM 160°SHUT DOWN 180°2) RTD TERMINAL BOX (1/PUMP)NEMA 4X, 316SS, 1” ALUMINUM CONDUIT

Hello Mike,Based on the information you had previously provided, together with the bearing loads, pleasesee our recommendations below.We ran bearing operating temperature estimate calculations. Depending on the heat dissipationproperties of your housing, we estimate both bearing operating temperatures to be about:- -5°C to 0°C, at an ambient of -15°C (5 °F), and- 55°C to 60°C, at an ambient of 49°C (120°F).As I mentioned in a previous email, we would recommend a wide temperature grease, with asynthetic base oil, and Polyurea or Lithium complex thickener, of NLGI 2 consistency, with goodrust/corrosion and water resistance characteristics. Examples of such greases would be: MobilithSHC 100, Klueber Asonic GHY 72, or similar.Regarding relubrication intervals:The full grease replenishment amount for each bearing is roughly 36.9g for the 5217A, and 52.5gfor the back-to-back pair of 7314 BECBY's.Under continuous operation, we would recommend these bearings be relubricated about every20,000 hours. However, since these bearings are not typically in operation, we wouldrecommend that the bearings be recharged with about half of the replenishment amounts above,about once every quarter, in order to flush out any moisture, or other potential contaminants, thatmay have migrated towards the inner bearing surfaces.I hope you find the above information helpful.Best regards,Rolando H. AcevedoApplications EngineerSKF USA, Inc.Industrial Division890 Forty Foot RoadP.O. Box 352Lansdale, PA 19446Tel: 267 436 6454 Mobile: 609 254 7760Fax: 267 436 6029Rolando.H.Acevedo@skf.com www.skfusa.comAny technical assistance or advice provided by SKF either written or oral is subject to SKF’s General Conditionsfor technical assistance and advice which can be viewed by clicking this link www.skf.com/files/883520.pdf .

MATERIAL LISTITEM DESCRIPTION MATERIAL1A Lower Casing ASTM A48 CL30 C. I. w/Mat Certif and Coupon1B Upper Casing ASTM A48 CL30 C. I. w/Mat Certif and Coupon2 Impeller ASTM B148-958 Al Bronze w/Mat Certif and Coupon6 Shaft AISI 4340 (quenched and tempered)7 Casing Ring ASTM B505-952 Bronze8 Impeller Ring ASTM B505-958 Bronze13A Sleeve O-Ring Nitrile14 Shaft Sleeve AISI 316 SS16 Inboard Bearing Steel SKF Standard17 Packing Gland AISI 316 S. S.17A Gland Bolts, Nuts AISI 31618 Outboard Bearing Steel SKF Standard20 Shaft Sleeve Nut AISI 316 SS20A Sleeve Nut Set Screws AISI 316 SS<strong>22</strong> Bearing Locknut Steel31 Inboard Bearing Housing ASTM A48-CL30 C. I.31A Bearing Brackets ASTM A48-CL30 C. I.32 Impeller Key AISI 316 SS33 Outboard Bearing Housing ASTM A48-CL30 C. I.35 Bearing Cover (Inboard) ASTM A48-CL30 C. I.37 Bearing Cover (Outboard) ASTM A48-CL30 C. I.40 Deflector Aluminum40A Bearing Lip Seal Nitrile41,41A Bearing Caps ASTM A48-CL30 C. I.46 Coupling Key Carbon Steel69 Bearing Lockwasher Steel SKF Standard127 Seal Water Piping Copper TubingDrain PipingCarbon SteelAll Bolts, Nuts, PinsAISI 316 SSPump Base (Stress Relieved) ASTM A36 SteelCoupling GuardASTM A36 Steel

SPEED/TORQUE CURVES.Serial Number: SC-C<strong>01</strong>09398Shutoff conditions ( valve closed):Pump Type:18x14MABFull Load Speed (rpm):n = 1.18 × 10 3Motor: SIEMENS 400HP/1200RPMFull Load Power (bhp):P = 153.424IMPELLER WR^2 : 166 lbs-ft^2 Full Load Torque(lb-ft): T = 682.882700SHUTOFF ( DISCHARGE VALVE CLOSED)650600550500TORQUE( lbs-ft)450Y( X)40035030025020<strong>01</strong>5<strong>01</strong>000 100 200 300 400 500 600 700 800 900 1× 10 3 1.1× 10 3 1.2×10 3n⋅XRPM

Serial Number: SC-C<strong>01</strong>09398Runout conditions ( valve open):Pump Type:18x14MABFull Load Speed (rpm):n = 1.18 × 10 3Motor: SIEMENS 400HP/1200RPMFull Load Power (bhp):Pm = 391.34IMPELLER WR^2 : 166 lbs-ft^2 Full Load Torque(ft-lbf): Tm = 1.742 × 10 3TORQUE( lbs-ft)Ym( X)1.8×10 31.7×10 31.6×10 31.5×10 31.4×10 31.3×10 31.2×10 31.1×10 31×10 3900800RUNOUT ( DISCHARGE VALVE OPEN)7006005004003002000 100 200 300 400 500 600 700 800 900 1× 10 3 1.1× 10 3 1.2×10 3n⋅XRPM

ABCDEFGHJKLMNPRSTUVWX1ZONEREV ECRDATEBY1 31774 <strong>01</strong>/13/2<strong>01</strong>2 TRJ1<strong>23</strong>45678910<strong>11</strong>12131415O <strong>22</strong>.75577.9BOLTCIRCLENOTE: 1) CLOCKWISE ROTATION SHOWN WHEN VIEWED FROMDRIVER END, SUCTION ON RIGHT, DISCHARGE ON LEFT.2) GROUT HOLES ARE PROVIDEDIMPORTANT; BASES MUST BE GROUTED TO THEIR FULL DEPTH.3) ALL DIMENSIONS UNLESS SPECIFIED OTHERWISE ARE INCHES.4) ALL DIMENSIONS ARE +/- 1/4" / 6.4mm (EXCEPT FOR FLANGE DRILLING).5) ALL SECONDARY DIMENSIONS ARE MILLIMETERS.17.50444.5APPROX. WEIGHTS:PUMP = 7,200 LBS. / 3,266 KGS.MOTOR = 5,050 LBS. / 2,291 KGS.BASE = 1,550 LBS. / 703 KGS.TOTAL= 13,800 LBS. / 6,260 KGS.1.7544.5125#18" SUCTIONO25.25 [641.4] FLANGE125# BOLT PATTERN16 O1.25 [31.8] BOLT HOLESB.C. STRADDLES CLA B C35.00889.0TOP VIEW<strong>11</strong> <strong>11</strong>7.502984.528.00 134.257<strong>11</strong>.2870.<strong>01</strong>26.00660.4.389.5BETWEENHUBS2.1354.0NEMA 4XRTD JUNCTION BOX19.38492.138.13968.4DRIPRIM1" NPTDRAINO 18.75PUMP C L476.3PUMP C L BOLT20.75527.0<strong>22</strong>.00558.8144.00<strong>11</strong>17.620.75527.1<strong>22</strong>.00558.812X O1.00 [25.4] HOLES(LOWER FLANGE ONLY)CIRCLE6.38162.<strong>11</strong>25#14" DISCHARGEO<strong>23</strong> [584.2] FLANGE125# BOLT PATTERN12 O1.13 [28.6] BOLT HOLESB.C. STRADDLES CL3.0076.2PATTERSON PUMP COMPANYA GORMAN-RUPP COMPANYOUTLINE DIMENSIONS18X14 MABW/SIEMENS 50<strong>11</strong>SYD E F G H J K L MN P R S T U31.00787.426.00660.4R26.00660.4<strong>22</strong>.80579.<strong>01</strong>36.003454.4135.553443.<strong>01</strong> 1.5<strong>01</strong>2.71 72.8<strong>01</strong>849.154.751390.7BETWEEN SHAFTS29.20741.826.00660.4CONDUITBOXDWG. NO.DRAWNC02-1<strong>22</strong>577tjordanSCALENONE36.64930.61.5038.1GROUTMINDATEAPPRVD.MSREV.<strong>11</strong>2/16/20<strong>11</strong>V W X<strong>23</strong>45678910<strong>11</strong>12131415

SABCDEFGHJKLMNPRSTUVWXTHIRD ANGLE PROJECTIONZONEREVECRDATEBY1<strong>22</strong>2A1841A40APIN79427020(INSTALLED AT ASSEMBLY)4<strong>01</strong>7 13A 13 29GREASE FITTING 1/4" NPT7600003920 20A 4041 16 <strong>22</strong>3140A406SSCP 3/8"8126331<strong>23</strong>14DETAIL C734PIN79427008(INSTALLED AT ASSEMBLY)455DETAIL D669A3337DETAIL A35DETAIL B6946678910<strong>11</strong>1213O <strong>22</strong>.751/4" NPT PLUG7407000217.50444.51.7544.525.00635.0DIRECTION ARROW760<strong>01</strong>493CAUTION PLATE<strong>23</strong>0<strong>01</strong>00<strong>01</strong>/2" NPT PLUGJACK BOLTARV PORT4" NPTPLUGGEDPUMP C L40.0<strong>01</strong><strong>01</strong>6.0RTDCAST-ON LIFTING LUGS2.1354.0<strong>23</strong>.00584.2DOWEL PIN79415024NAMEPLATE<strong>23</strong>000263577.9 BOLT CIRCLE 3/4" NPT PLUG125#7407003<strong>01</strong>25#18" SUCTION16X O1.25 [31.8] BOLT HOLESEQ. SP. ON BOLT CIRCLEB.C. STRADDLES C3/4" NPT DRAIN1/2" NPT PLUG74070004GASKET7404000919.38492.1O 18.75476.3BOLT CIRCLEA14" DISCHARGE12X O1.13 [28.6] BOLT HOLESEQ. SP. ON BOLT CIRCLEB.C. STRADDLES C31A28.007<strong>11</strong>.<strong>23</strong>2C2DPUMP C L36.00914.4USA31.00787.41B34.25870.<strong>01</strong>271A31A1.5038.1B28.007<strong>11</strong>.2ITEM DESCRIPTION1A LOWER CASING (<strong>23</strong>029036)1B UPPER CASING (<strong>23</strong>029036)2 IMPELLER6 SHAFT (<strong>23</strong><strong>01</strong>8855)7 CASING RING (<strong>23</strong>007518)8 IMPELLER RING13 PACKING13A SLEEVE O-RING (74080343)14 SHAFT SLEEVE (<strong>23</strong>000887)16 INBOARD BEARING (74<strong>01</strong><strong>01</strong>55)17 PACKING GLAND17A GLAND BOLTS, NUTS18 OUTBOARD BEARING (74<strong>01</strong>0046)20 SHAFT SLEEVE NUT (<strong>23</strong>0304<strong>11</strong>)20A SLEEVE NUT SET SCREWS<strong>22</strong> INBOARD BEARING LOCKNUT (74<strong>01</strong>0<strong>11</strong>0)<strong>22</strong>A OUTBOARD BEARING LOCKNUT (74<strong>01</strong><strong>01</strong>07)29 LANTERN RING31 INBOARD BEARING HOUSING (<strong>23</strong>030490)31A BEARING BRACKETS (<strong>23</strong>004772)32 IMPELLER KEY (<strong>23</strong>141456)33 OUTBOARD BEARING HOUSING (<strong>23</strong>025736)35 BEARING COVER (INBOARD) <strong>23</strong>030491)37 BEARING COVER (OUTBOARD) (<strong>23</strong>030491)40 DEFLECTOR40A BEARING LIP SEAL41 INBOARD BEARING CAP (<strong>23</strong>004772)41A OUTBOARD BEARING CAP (<strong>23</strong>004772)46 COUPLING KEY (<strong>23</strong>105457)63 STUFFING BOX BUSHING65 MECHANICAL SEAL69 INBOARD BEARING LOCKWASHER (74<strong>01</strong>0081)69A OUTBOARD BEARING LOCKWASHER (74<strong>01</strong>0078)1<strong>23</strong> BEARING END COVER127 SEAL WATER PIPING78910<strong>11</strong>1213DIMENSIONS IN ( ) ARE FOR REFERENCE ONLYALL PRIMARY DIMENSIONS ARE IN INCHES AND SECONDARY DIMENSIONS, SHOWN IN [ ], ARE IN MILLIMETERS1415A B CASSEMBLE PUMPS IN CLOCKWISE ROTATIONSOME ITEMS SHOWN ROTATED FOR CLARITYRUNOUT (TOTAL)D02-106660 C<strong>01</strong>09398 254743 OVER 24" ± .19"D E F G H J K L MN P R S T UREF A.N.S.I. Y 14.5 1994CHARACTERISTICPROFILE OF A LINEPROFILE OF SURFACEAT MAX. MATERIALCONDITIONAT LEAST MATERIALCONDITIONREGARDLESS OFFEATURE SIZESYMBOLMLSDIAMETERDATUM FEATUREDEPTHROUNDNESSFLATNESSPARALLELISMPERPENDICULARITY(SQUARENESS)COUNTERBORE(BACK SPOT)-A-ANGULARITYPOSITIONCONCENTRICITYRUNOUT (CIRCULAR)COUNTERSINKSTRAIGHTNESSTHIS DOCUMENT CONTAINS DESIGNS ANDOTHER INFORMATION WHICH ARE THECONFIDENTIAL PROPERTY OF PATTERSON PUMPCOMPANY. THE RECIPIENT ACKNOWLEDGESTHAT THIS IS FURNISHED FOR ITS PRIVATE USEAND UPON THE EXPRESS AGREEMENT THAT ITWILL NOT REPRODUCE, COPY, EXHIBIT OR LENDIT IN WHOLE OR IN PART FOR ANY PURPOSEWHAT SO EVER WITHOUT THE PRIOR WRITTENCONSENT OF PATTERSON PUMP COMPANY.DWG REF #MACHINIST NOTE:BREAK ALL SHARP CORNERS TO A .02 X 45° CHAMFERORDER NUMBERJOB NUMBERPRIMARYTOLERANCES(EXCEPT AS NOTED)2 PLC DEC.3 PLC DEC.ANGULARTORCH CUTFABRICATIONUP TO 6"6" TO 24"± .03"± .005"± 1°± .06"± .06"± .12"TITLEASSEMBLY SECTION18 X 14 MAB SIDE SUCTIONGREASE LUBE W/PACKINGSHEET OFDRAWN1 1tjordanRPATTERSON PUMP COMPANYA SUBSIDIARY OF THE GORMAN-RUPP COMPANYSCALECHECKED1/8"=1"APPROVEDDRAWING NUMBERD02-1<strong>22</strong>582PATTERN NUMBERPART NUMBERDATEMS MS 1/13/2<strong>01</strong>2V W XREV.<strong>01</strong>415

THIS DOCUMENT CONTAINS DESIGNS AND OTHERINFORMATION WHICH ARE THE CONFIDENTIAL PROPERTYOF PATTERSON PUMP COMPANY. THE RECIPIENTACKNOWLEDGES THAT THIS IS FURNISHED FOR ITSPRIVATE USE AND UPON THE EXPRESS AGREEMENT THATIT WILL NOT REPRODUCE, COPY, EXHIBIT OR LEND IT INWHOLE OR IN PART FOR ANY PURPOSE WHAT SO EVERWITHOUT THE PRIOR WRITTEN CONSENT OF PATTERSONPUMP COMPANY.2 PLC DEC.3 PLC DEC.NAMEPLATEANGULAR ± 1°(PATTERSON STD. PUMPS)TORCH CUT ± .06"MACHINIST NOTE:SHEET OFSCALEFABRICATIONBREAK ALL SHARP CORNERS TO A .02 X 45° CHAMFERUP TO 6" ± .06" 1 <strong>11</strong>:1 .061.5 TYP10 28510 DEC. 15, 2009 MC± .12" DRAWNCHECKEDOVER 24" ± .19" CHILDSAPMATL: S.S.4.50<strong>11</strong>4.34.<strong>22</strong>107.2REV ECR DATE BYDIMENSIONS IN ( ) ARE FOR REFERENCE ONLYA SUBSIDIARY OF THE GORMAN-RUPP CO..19TOCCOA, GEORGIA4.8 TYP 1.94.256.4 TYP.8120.6 TYPPRIMARYTOLERANCES(EXCEPT AS NOTED)SIZE - TYPECAPACITY± .03"± .005"TITLE6" TO 24" APPROVEDR.P.M.SERIAL NO.HEADMade in U.S.A. of U.S. and imported partsRRPATTERSON PUMP COMPANYA SUBSIDIARY OF THE GORMAN-RUPP COMPANYDRAWING NUMBERE-<strong>11</strong>351PATTERN NUMBERPART NUMBERAP<strong>23</strong>000263ALL PRIMARY DIMENSIONS ARE IN INCHES AND SECONDARY DIMENSIONS, SHOWN IN [ ], ARE IN MILLIMETERS18 X 14 MAB SC-C<strong>01</strong>09398-<strong>01</strong>6944 GPM 179 FT.<strong>11</strong>8<strong>01</strong>.561.3839.7 TYP .3134.97.949.2 TYP.194.8 TYPDATE3.0076.<strong>22</strong>.7269.1 TYPREV.10JAN. 7, 1994

INDUCTION MOTOR DATASiemens Industry, Inc.Norwood, OhioCustomer : PATTERSON PUMPSOrder Number : 3003627653-000<strong>01</strong>0SPECIFIED REQUIREMENTSFRAME DATAHorsepower : 400 Frame : 50<strong>11</strong>SYService Factor : 1.15 Type : CZVoltage : 460 Rotor <strong>Construction</strong> : Fabricated Copper BarNumber of Phases : 3 Load Inertia (wk2), lb-ft2 : 166Frequency, hertz : 60 Rotor Inertia (wk2), lb-ft2 : 205Ambient, deg C : 50 Rotor Weight, lbs : 1251Enclosure : TEFC Motor Weight, lbs : 5150Synchronous Speed, RPM : 1200 Temp. Rise : 80 by DET @ 1SFPercent Starting Voltage : 80 Sound Pressure Level : 80dBA @ 3ft, unloadedElevation (ft) : 3300 Insulation Class : F-VPIMaximum PF Correction (kVAR) : 130 Insulation Voltage Rating : 600 voltsGuaranteed Min. FL Efficiency (%) : 94.1PERFORMANCE DATA (Open Valve Load Curve)Full Load Speed, RPM : <strong>11</strong>83 Full Load Torque, lb-ft : 1776Current, Amps : 487 Starting Torque, %FLT : 129Locked Rotor Current, % FLA : 576 Breakdown Torque, %FLT : <strong>22</strong>6KVA/Hp : 5.59 NEMA Design : -Code : F0.25 0.50 0.75 Full 1.15 No LockedLoad Load Load Load Load Load RotorPercent Efficiency : 92.1 94.5 94.8 94.4 94.1 N/A N/APercent Power Factor : 46.5 68.7 77.8 81.4 82.2 3.8 <strong>22</strong>.6Current, Amps : 218.6 288.4 380.8 487.4 556.8 180.6 2807% Voltage % FLARTD Settings (°C):100 80 350 Alarm ShutdownSafe Stalled Time, Motor Hot (sec) : 21.0 40.0 61.0 Stator: 155 170Safe Stalled Time, Motor Cold (sec) : 25.0 46.0 71.0 Bearings: 100 105Acceleration Time (sec) : 0.7 1.4 2.2Time Constants : 0.460 Seconds Open Circuit0.029 Seconds Short Circuit (AC)X/R Ratio : 19.689X"d : 0.0974Starting Duty:Number of starts, coasting to a rest between starts:3 starts with motor initially at ambient temperature (cold)2 starts with motor at service factor operating temperature (hot)Cooling period, after either of above before making an additional start:30 minutes, motor running at service factor load.20 minutes, motor running, equipment unloaded.60 minutes, motor de-energized, coasted to a rest and left idle.Prepared by Z MERANA on 02/07/12Please Note:1. All values are typical.2. Guaranteed values are indicated in (GUAR)

Percent Full Load Torque (Solid)Percent Rated Current (Dashed)Siemens Industry, Inc.Induction MotorPercent Full Load Current and Torque vs. Percent Speed250.00700.00600.00200.00500.0<strong>01</strong>50.00400.0<strong>01</strong>00.00300.00200.0050.00Open Valve Load Curve100.000.000.000.00 10.00 20.00 30.00 40.00 50.00 60.00 70.00 80.00 90.00 100.00Percent Synchronous SpeedSO Number: 3003627653-000<strong>01</strong>0HP: 400 HPRated Voltage: 460 VRated Current: 487.4 ARated Speed: <strong>11</strong>83 RPMDate: 2/7/2<strong>01</strong>2Curve groups fromTop to Bottom are1.00, 0.80 Rated Voltage350% Rated Amps

Time in Seconds1000Siemens Industry, Inc.Induction MotorCalculated Time vs. Percent Full Load Current100RunningCold StalledHot Stalled1<strong>01</strong>BEA0.10 100 200 300 400 500 600 700Percent Full Load CurrentSO Number: 3003627653-000<strong>01</strong>0HP: 400 HPRated Voltage: 460 VRated Current: 487.4 ARated Speed: <strong>11</strong>83 RPMDate: 2/7/2<strong>01</strong>2A = 100% Voltage StartB = 90% Voltage StartE = 350% Current Limited Start

Eff & PF(%)Amps97.0Siemens Industry, Inc.Induction MotorCalculated Eff, PF, & Amps vs. per unit Load700.087.0600.0500.077.0400.067.0300.0EffPFAmps57.0200.047.<strong>01</strong>00.037.00.00 0.20 0.40 0.60 0.80 1.00 1.20Load(pu)0.0SO Number: 3003627653-000<strong>01</strong>0HP: 400 HPRated Voltage: 460 VRated Current: 487.4 ARated Speed: <strong>11</strong>83 RPMDate: 2/7/2<strong>01</strong>2

INDUCTION MOTOR DATASiemens Industry, Inc.Norwood, OhioCustomer : PATTERSON PUMPSOrder Number : 3003627653-000<strong>01</strong>0SPECIFIED REQUIREMENTSFRAME DATAHorsepower : 400 Frame : 50<strong>11</strong>SYService Factor : 1.15 Type : CZVoltage : 460 Rotor <strong>Construction</strong> : Fabricated Copper BarNumber of Phases : 3 Load Inertia (wk2), lb-ft2 : 166Frequency, hertz : 60 Rotor Inertia (wk2), lb-ft2 : 205Ambient, deg C : 50 Rotor Weight, lbs : 1251Enclosure : TEFC Motor Weight, lbs : 5150Synchronous Speed, RPM : 1200 Temp. Rise : 80 by DET @ 1SFPercent Starting Voltage : 80 Sound Pressure Level : 80dBA @ 3ft, unloadedElevation (ft) : 3300 Insulation Class : F-VPIMaximum PF Correction (kVAR) : 130 Insulation Voltage Rating : 600 voltsGuaranteed Min. FL Efficiency (%) : 94.1PERFORMANCE DATA (Closed Valve Load Curve)Full Load Speed, RPM : <strong>11</strong>83 Full Load Torque, lb-ft : 1776Current, Amps : 487 Starting Torque, %FLT : 129Locked Rotor Current, % FLA : 576 Breakdown Torque, %FLT : <strong>22</strong>6KVA/Hp : 5.59 NEMA Design : -Code : F0.25 0.50 0.75 Full 1.15 No LockedLoad Load Load Load Load Load RotorPercent Efficiency : 92.1 94.5 94.8 94.4 94.1 N/A N/APercent Power Factor : 46.5 68.7 77.8 81.4 82.2 3.8 <strong>22</strong>.6Current, Amps : 218.6 288.4 380.8 487.4 556.8 180.6 2807% Voltage % FLARTD Settings (°C):100 80 300 Alarm ShutdownSafe Stalled Time, Motor Hot (sec) : 21.0 40.0 84.0 Stator: 155 170Safe Stalled Time, Motor Cold (sec) : 25.0 46.0 97.0 Bearings: 100 105Acceleration Time (sec) : 0.6 1.0 2.1Time Constants : 0.460 Seconds Open Circuit0.029 Seconds Short Circuit (AC)X/R Ratio : 19.689X"d : 0.0974Starting Duty:Number of starts, coasting to a rest between starts:3 starts with motor initially at ambient temperature (cold)2 starts with motor at service factor operating temperature (hot)Cooling period, after either of above before making an additional start:30 minutes, motor running at service factor load.20 minutes, motor running, equipment unloaded.60 minutes, motor de-energized, coasted to a rest and left idle.Prepared by Z MERANA on 02/07/12Please Note:1. All values are typical.2. Guaranteed values are indicated in (GUAR)

Percent Full Load Torque (Solid)Percent Rated Current (Dashed)Siemens Industry, Inc.Induction MotorPercent Full Load Current and Torque vs. Percent Speed250.00700.00600.00200.00500.0<strong>01</strong>50.00400.0<strong>01</strong>00.00300.00200.0050.0<strong>01</strong>00.00Closed Valve Load Curve0.000.000.00 10.00 20.00 30.00 40.00 50.00 60.00 70.00 80.00 90.00 100.00Percent Synchronous SpeedSO Number: 3003627653-000<strong>01</strong>0HP: 400 HPRated Voltage: 460 VRated Current: 487.4 ARated Speed: <strong>11</strong>83 RPMDate: 2/7/2<strong>01</strong>2Curve groups fromTop to Bottom are1.00, 0.80 Rated Voltage300% Rated Amps

SIEMENSInduction MotorSer.No. 3003627653-10 Type CZ Date of MFG.H.P. 400 Frame 50<strong>11</strong>SY Service1.15FactorAmps 487 Volts 460 Class Insul. F-VPIR.P.M. <strong>11</strong>83 Hertz 60 NEMA Nom. Eff.Duty CONT. AMB Phase 3 KVA FNEMA50CCodeDesignSh. End 75BC02J3BRGSPACE HEATERS : 120/240V 525WEnd Opp.BRGMAX POWER FACTOR CORRECTION = 130 kVAR75BC02J3OperatingInstructionRotating Facing Drive End with Phase Sequence A-B-CCCW A-T 1 B-T 2 C-T 3 CW A-T 3 B-T 2 C-T 1Siemens Energy & Automation, Inc. Norwood OHMade in USAFiled under: NPDRWG.DOT M-<strong>11</strong>0 (9/20/95)

ÚßÍÌŽÍ rÙ»¿® ݱ«°´·²¹Í·¦» ï ïñî ¬¸®±«¹¸ íðÚßÍÌŽÍ r Ó±¼»´ ÞÙ»¿® ݱ«°´·²¹Í·¦» ï ¬¸®±«¹¸ í ïñî̸» ײ¼«¬®§ ͬ¿²¼¿®¼º±® Ѫ»® èð Ç»¿®Ë²·¯«» ß´´ó³»¬¿´Û²¼ η²¹ Í»¿´Ü»·¹²»¼ º±®Ó¿¨·³«³ Í»®ª·½» Ô·º»Ú±® Ó±®»×²º±®³¿¬·±²Ê··¬ ©©©òµ±°º´»¨ò½±³×²¼»¨æп¹»ØÑÉ ÌÑ ÑÎÜÛÎ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòïíïÚßÍÌŽÍ rÌ»½¸²·½¿´ ß¼ª¿²¬¿¹»òòòòòòòòòòòòòòòòòòò ïíð ó ïíïÍ»®ª·½» Ú¿½¬±®òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòïíîÍ»´»½¬·±² Ю±½»¼«®» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòïííܧ²¿³·½ Þ¿´¿²½·²¹ Ù«·¼» òòòòòòòòòòòòòòòòòòòòòòïííÚ«´´ Ú´»¨ ݱ«°´·²¹ òòòòòòòòòòòòòòòòòòòòòòòòò ïíì ó ïíêÚ¿¬»²»® Ü¿¬¿ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïíì ó ïíëÍ°¿½»® ݱ«°´·²¹ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòïíéÚ´»¨ η¹·¼ ݱ«°´·²¹ òòòòòòòòòòòòòòòòòòòòòò ïíè ó ïíçÚ´±¿¬·²¹ ͸¿º¬ ݱ«°´·²¹ òòòòòòòòòòòòòòòò ïíè ó ïíçÓ·´´ Ó±¬±® ݱ«°´·²¹ òòòòòòòòòòòòòòòòòòòòòòò ïìð ó ïìïÔ·³·¬»¼ Û²¼ Ú´±¿¬ ݱ«°´·²¹ òòòòòòòòòòòòòòòòòòòòïìîη¹·¼ ݱ«°´·²¹ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòïìî͸±®¬ Í´·¼» ݱ«°´·²¹òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòïìíÓ»¼·«³ Í´·¼» ݱ«°´·²¹ òòòòòòòòòòòòòòòòòòòòòòòòòòïììÔ±²¹ Í´·¼» ݱ«°´·²¹ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòïìëÝ«¬±«¬ ̧°» ÚÝØô ÚÝÝ ú ÚÝÝÓ òòòòòòòòòòïìȩ̂°» ÍØ Í¸·º¬»® ݱ´´¿® òòòòòòòòòòòòòòòòòòòòòòòòòòòòïìȩ́°» ÝÓ Ó¿²«¿´ ͸·º¬»® Ó»½¸¿²·³ òòòòòïìéܱ«¾´» Û²¹¿¹»³»²¬ ø̧°» ÜÛ÷òòòòòòòòòòòòòòïìèݱ²¬·²«±« Ô«¾» ̧°» ÚÍÝÔòòòòòòòòòòòòòòòòòòïìçÓ»¼·«³ Í´·¼» Ö±®¼¿² ̧°» ÖÓÍ òòòòòòòòòòòòòïëðÛ¨¬®¿ Ô±²¹ Í´·¼» ̧°» ÚÈÔÍòòòòòòòòòòòòòòòòòòòïëïÚ«´´óÌ®¿ª»´ ̧°» ÚÌÍ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòïëïݱ³¾·²¿¬·±² ú ײ¬»®³»¼·¿¬» Í´·¼»òòòòòòòòòòïëïÊ»®¬·½¿´ ̧°» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïëî ó ïëìÞ®¿µ» ɸ»»´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòïëëÓ±¼»´ ÞÌ»½¸²·½¿´ ß¼ª¿²¬¿¹»òòòòòòòòòòòòòòòòòòòòòòòòòòòòòïëêÚ´»¨ η¹·¼ ݱ«°´·²¹ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòïëêÚ´±¿¬·²¹ ͸¿º¬ ݱ«°´·²¹ òòòòòòòòòòòòòòòòòòòòòòòòòòïëêÚ«´´ Ú´»¨ ݱ«°´·²¹ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòïëéÔ·³·¬»¼ Û²¼ Ú´±¿¬ ݱ«°´·²¹ òòòòòòòòòòòòòòòòòòòòïëèÍ°¿½»® ݱ«°´·²¹ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòïëèïîç

ÚßÍÌŽÍ r Ù»¿® ݱ«°´·²¹É¸§ Í°»½·º§ ÚßÍÌŽÍ r Ù»¿® ݱ«°´·²¹á̸» ÚßÍÌŽÍ r ¼»·¹²ô ©·¬¸ ·¬ ´·º»¬·³» ¿´´ó³»¬¿´ »²¼ ®·²¹ô°®±ª·¼» «° ¬± íððû ¹®»¿¬»® ´«¾®·½¿²¬ ½¿°¿½·¬§ò ̸· ³»¿²¬¸¿¬ ´±²¹»® °»®·±¼ ¾»¬©»»² ®»´«¾®·½¿¬·±² ³¿§ ¾» ½¸»¼«´»¼òÑó®·²¹ÚßÍÌùÍ rÔ«¾®·½¿²¬ Ý¿°¿½·¬§ ó ÚßÍÌŽÍ r ªò Ñó®·²¹ ͬ§´»É¸§ × Ì¸» Ü»·¹² ˲·¯«»á̸» ¿´´ó³»¬¿´ »²¼ ®·²¹ô «»¼ »¨½´«·ª»´§ ·² ÚßÍÌŽÍ r ½±«°´·²¹ô»´·³·²¿¬» ¬¸» ²»»¼ º±® ¿²§ ¬§°» ±º °»®·¸¿¾´» ´«¾» »¿´ ø±ó®·²¹ô´·° »¿´ô ½±®µ ¹¿µ»¬ô »¬½ò÷ò ̸» »²¼ ®·²¹ ²±¬ ±²´§ °®±ª·¼» ¬¸»¼¿³ ±ª»® ©¸·½¸ ´«¾®·½¿²¬ ³«¬ º´±© ¬± »½¿°»ô ¾«¬ ·¬ ¿¼¼·¬·±²¿´´§°·´±¬ ¬¸» ´»»ª» ©·¬¸ ®»°»½¬ ¬± ¬¸» ¸«¾ ¼«®·²¹ ¬¿®¬ó«° ¿²¼ ¸«¬ó¼±©² ±°»®¿¬·±²ò ׬ º«®¬¸»® »´·³·²¿¬» °¿®¬·¿´ ¬±±¬¸ ¼·»²¹¿¹»³»²¬©·¬¸ ®»«´¬·²¹ ¬±±¬¸ ±ª»®´±¿¼ ¾§ °®±ª·¼·²¹ ´»»ª» ¬»»¬¸ ©¸·½¸¿®» º´«¸ ¿¹¿·²¬ ¬¸» ·²·¼» ©¿´´ ±º ¬¸» »²¼ ®·²¹òÚßÍÌŽÍ r Ù»¿® ݱ«°´·²¹ Í·¦» ï ïñî ó éɸ¿¬ ̱±¬¸ Ú±®³ × Ë»¼á̸» ͬ®¿·¹¸¬óÚ¿½»¼ ·²ª±´«¬» ¸«¾ ¬±±¬¸ º±®³ º»¿¬«®»¼ ·² ¬¸»ÚßÍÌŽÍ r ½±«°´·²¹ · ª·®¬«¿´´§ «²·¯«» ·² ¬¸» ·²¼«¬®§ ¬±¼¿§ò ׬ ·¬¸· ¬±±¬¸ º±®³ ¬¸¿¬ ¼·¬®·¾«¬» ¬±±¬¸ ½±²¬¿½¬ °®»«®» ¿½®±¬¸» º«´´ ´»²¹¬¸ ±º ¬¸» ¸«¾ ¬±±¬¸ô ¾»¬ ¼»ª»´±°·²¹ ¬¸» ²»»¼»¼¸§¼®±¼§²¿³·½ ´«¾» º·´³ô ³·²·³·¦·²¹ ¬±±¬¸ ©»¿® ¿²¼ »¨¬»²¼·²¹½±«°´·²¹ ´·º»ò ׬ · ¬¸» ±²´§ ¸«¾ ¬±±¬¸ º±®³ ¿ª¿·´¿¾´» ·² ¬¸»¬¿²¼¿®¼ ÚßÍÌŽÍ r ½±«°´·²¹ ´·²»ò׬ · ¬¸» ±²´§ ½±«°´·²¹ ¼»·¹²»¼ ¬± «» ±·´ ´«¾®·½¿¬·±²ò̱ ¾» «®» ¬¸¿¬ §±«® ½±«°´·²¹ °®±ª·¼» Ó¿¨·³«³ Ô·º»ô ¿´©¿§°»½·º§ ÚßÍÌŽÍ r ½±«°´·²¹ô ©·¬¸ ¬¸» ¿´´ó³»¬¿´ »²¼ ®·²¹ÿͬ®¿·¹¸¬óÚ¿½» ̱±¬¸ïcp Ý«®ª»¼ Ú¿½» ̱±¬¸ï̱±¬¸ Ó±¬·±² ˲¼»® Ó·¿´·¹²³»²¬ïíð

ÚßÍÌŽÍ r Ù»¿® ݱ«°´·²¹Ì¸» ÚßÍÌŽÍ r ݱ«°´·²¹Ì¸» ÚßÍÌŽÍ r ¹»¿® ½±«°´·²¹ ·¿ª¿·´¿¾´» ·² ¬©± ¾¿·½ °®±¼«½¬ ´·²»æ¡ ÚßÍÌŽÍ r ½±«°´·²¹ º±® ³»¼·«³ ¬±¸»¿ª§ó¼«¬§ ¿°°´·½¿¬·±²ò‰ Í·¦» ï ïñî ¬¸®±«¹¸ é ©·¬¸·²¬»¹®¿´ »²¼ ®·²¹ò‰ Í·¦» è ¬¸®±«¹¸ íð ©·¬¸ ¾±´¬ó±² »²¼ ®·²¹ò¡ ÚßÍÌŽÍ r Ó±¼»´ Þ ½±«°´·²¹ º±®´·¹¸¬ ¬± ³»¼·«³ó¼«¬§ ¿°°´·½¿¬·±²òÓ±¼»´ Þ ½±«°´·²¹ ¿®» ²±¬·²¬»®½¸¿²¹»¿¾´» ©·¬¸ ¬¿²¼¿®¼ÚßÍÌŽÍ r ½±«°´·²¹ò‰ Í·¦» ï ïñî ¬¸®±«¹¸ í ïñî©·¬¸ ·²¬»¹®¿´ »²¼ ®·²¹òÝ»²¬»® Ú´¿²¹» Þ±´¬·²¹æß´´ ½±«°´·²¹ º»¿¬«®» °®»½··±²ó¼®·´´»¼º´¿²¹» ¾±´¬ ¸±´»ô ¿²¼ ¬·¹¸¬ ¬±´»®¿²½»Ù®¿¼» ë º´¿²¹» ¾±´¬ ¬± ¿«®» ¿ ´±²¹ó´¿¬·²¹ º´¿²¹» ¬± º´¿²¹» ¿²¼ º¿¬»²»® º·¬òÛ¨°±»¼ ¾±´¬ º´¿²¹» ¿®» ¬¿²¼¿®¼ò͸®±«¼»¼ ¾±´¬ º´¿²¹» ½¿² ¾» «°°´·»¼¬¸®±«¹¸ ·¦» ëò Í·¦» ýë ïñî ¿²¼ ´¿®¹»®½±«°´·²¹ ¿®» ±²´§ ¿ª¿·´¿¾´» ©·¬¸»¨°±»¼ ¾±´¬ º´¿²¹»ò͸¿º¬ Ó·¿´·¹²³»²¬æÛÈÐÑÍÛÜ ÞÑÔÌÍßÒÙËÔßÎÐßÎßÔÔÛÔ ÑÎ ÑÚÚÍÛÌÝÑÓÞ×ÒÛÜ øßÒÙËÔßÎ ú ÑÚÚÍÛÌ÷ÚßÍÌŽÍ r Ù»¿® ݱ«°´·²¹ Í·¦» èóíðÍØÎÑËÜÛÜ ÞÑÔÌÍÐÔËÍ ßÈ×ßÔ ÍØßÚÌ ÓÑÊÛÓÛÒÌÓ·¿´·¹²³»²¬ Ý¿°¿¾·´·¬·»ÚßÍÌŽÍ r ½±«°´·²¹ ¿®» ¼»·¹²»¼ º±®o ïñîp ¬¿¬·½ ³·¿´·¹²³»²¬ °»® ¸¿´º½±«°´·²¹òÓ·²·³·¦·²¹ ±°»®¿¬·²¹ ³·¿´·¹²³»²¬©·´´ ³¿¨·³·¦» ¬¸» ´·º» ±º ¬¸» ½±«°´·²¹òλº»® ¬± ¬¸» ײ¬¿´´¿¬·±² ¿²¼ß´·¹²³»²¬ ײ¬®«½¬·±² º±® ¿´·¹²³»²¬®»½±³³»²¼¿¬·±²òÐßÎÌ ÒËÓÞÛÎ ÛÈÐÔßÒßÌ×ÑÒݱ³°´»¬» α«¹¸ Þ±®» ݱ«°´·²¹ï ïñî Ú ÛÞ ÚÚݱ«°´·²¹ Í·¦»Ý±«°´·²¹ ͬ§´»Þ±´¬ ̧°»Ý±«°´·²¹ ̧°»Ú±® Ó±®»×²º±®³¿¬·±²Ê··¬ ©©©òµ±°º´»¨ò½±³ï ïñî ¬± í𠺱® ÚßÍÌŽÍ rï ¬± í ïñî º±® Ó±¼»´ ÞÚ ã ÚßÍÌŽÍ rÞ ã Ó±¼»´ ÞÛÞ ã Û¨°±»¼ Þ±´¬ÍÞ ã ͸®±«¼»¼ Þ±´¬ÚÚ ã Ú«´´ Ú´»¨ÚÎ ã Ú´»¨ η¹·¼ÓÓÚÚ ã Ó·´´ Ó±¬±® Ú«´´ Ú´»¨ÍÍÚÚ ã ͸±®¬ Í´·¼» Ú«´´ Ú´»¨ÍÍÚÎ ã ͸±®¬ Í´·¼» Ú´»¨ η¹·¼ÓÍÚÚ ã Ó»¼·«³ Í´·¼» Ú«´´ Ú´»¨ÔÍÚÚ ã Ô±²¹ Í´·¼» Ú«´´ Ú´»¨ï ïñîÚ ÚØËÞ ÚÞݱ«°´·²¹ п®¬Ü»½®·°¬·±²öÚØËÞ ã Ú´»¨ Ø«¾öÎØËÞ ã η¹·¼ Ø«¾öÓÓØËÞ ã Ó·´´ Ó±¬±® Ø«¾öÍÍØËÞ ã ͸±®¬ Í´·¼» Ø«¾ øÚ«´´ Ú´»¨÷öÍÎØËÞ ã ͸±®¬ Í´·¼» Ø«¾ øÚ´»¨ η¹·¼÷öÓÍØËÞ ã Ó»¼·«³ Í´·¼» Ø«¾öÔÍØËÞ ã Ô±²¹ Í´·¼» Ø«¾ÍÔÛÛÊÛ ã ͬ¿²¼¿®¼ Í´»»ª»ÓÍÍÔÛÛÊÛ ã Ó»¼·«³ Í´·¼» Í´»»ª»ÔÍÍÔÛÛÊÛ ã Ô±²¹ Í´·¼» Í´»»ª»ÚÍ ã Ú¿¬»²»® Í»¬ ø©ñ¹¿µ»¬÷ÊÍÚÍ ã Ê»®¬·½¿´ñÍ´·¼» Ú¿¬»²»® Í»¬ ø©ñ¹¿µ»¬÷ÛÎÚÍ ã Û²¼ η²¹ Ú¿¬»²»® Í»¬ÔÛÚÜ ã ÔÛÚ Ü·µÍÐΨ¨¨ ã Í°¿½»® º±® ¨ò¨¨ ¸¿º¬ »°¿®¿¬·±²ÍÐ ã ͬ±° д¿¬» º±® Í´·¼» ݱ«°´·²¹ÛÎ×ÒÙ ã Û²¼ η²¹öر© ¬± Ñ®¼»®Ú±® º·²·¸ ¾±®»¼ ¸«¾ô ¿¼¼ ÚÞ ¿²¼ ¾±®» ·¦»òß´´ º·²·¸ ¾±®» ¿²¼ µ»§©¿§ °»®ßÙÓß çððîóßèê ©·¬¸ ·²¬»®º»®»²½» º·¬òÝ´»¿®¿²½» ¾±®» ¿®» ¿ª¿·´¿¾´» ±² ®»¯«»¬©·¬¸ ±²» »¬½®»© ±ª»® µ»§©¿§òïíï

ÚßÍÌŽÍ r Ù»¿® ݱ«°´·²¹Í»®ª·½» Ú¿½¬±®Ê¿´«» ´·¬»¼ ¿®» ·²¬»²¼»¼ ±²´§ ¿ ¿ ¹»²»®¿´¹«·¼»ô ¿²¼ ¿®» ¬§°·½¿´ ±º ««¿´ »®ª·½»®»¯«·®»³»²¬ò Ú±® §¬»³ ©¸·½¸ º®»¯«»²¬´§«¬·´·¦» ¬¸» °»¿µ ¬±®¯«» ½¿°¿¾·´·¬§ ±º ¬¸» °±©»®±«®½»ô ª»®·º§ ¬¸¿¬ ¬¸» ³¿¹²·¬«¼» ±º ¬¸· °»¿µ¬±®¯«» ¼±» ²±¬ »¨½»»¼ ¬¸» ïòð Í»®ª·½»Ú¿½¬±® ο¬·²¹ ±º ¬¸» ½±«°´·²¹ »´»½¬»¼òß°°´·½¿¬·±² ©¸·½¸ ·²ª±´ª» »¨¬®»³» ®»°»¬·¬·ª»¸±½µ ±® ¸·¹¸ó»²»®¹§ ´±¿¼ ¿¾±®°¬·±²½¸¿®¿½¬»®·¬·½ ¸±«´¼ ¾» ®»º»®®»¼ ‰ ©·¬¸ º«´´°¿®¬·½«´¿® ‰ ¬± ÕÑÐóÚÔÛÈòÊ¿´«» ½±²¬¿·²»¼ ·² ¬¸» ¬¿¾´» ¿®» ¬± ¾»¿°°´·»¼ ¬± ³±±¬¸ °±©»® ±«®½» «½¸ ¿»´»½¬®·½ ³±¬±® ¿²¼ ¬»¿³ ¬«®¾·²»ò Ú±® ¼®·ª»·²ª±´ª·²¹ ·²¬»®²¿´ ½±³¾«¬·±² »²¹·²» ±º º±«®±® º·ª» ½§´·²¼»®ô ¿¼¼ ïò𠬱 ¬¸» ª¿´«» ´·¬»¼åº±® ·¨ ±® ³±®» ½§´·²¼»®ô ¿¼¼ ðòë ¬± ¬¸» ª¿´«»´·¬»¼ò Ú±® §¬»³ «¬·´·¦·²¹ ßÝ ±® ÜÝ Ó·´´Ó±¬±® ¿ ¬¸» °®·³» ³±ª»®ô ®»º»® ¬± Ò±¬» øï÷òß´´ °»±°´»³±ª·²¹¿°°´·½¿¬·±² ³«¬ ¾» ®»º»®®»¼ ¬± »²¹·²»»®·²¹ò̧°·½¿´ß°°´·½¿¬·±²Í»®ª·½»Ú¿½¬±®ßÙ×ÌßÌÑÎÍЫ®» Ô·¯«·¼ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòðÔ·¯«·¼ ú ͱ´·¼ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîëÔ·¯«·¼ ‰ Ê¿®·¿¾´» Ü»²·¬§ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîëÞÔÑÉÛÎÍÝ»²¬®·º«¹¿´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòðÔ±¾» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÊ¿²» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîëÞÎ×ÏËÛÌÌÛ ÓßÝØ×ÒÛÍ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÝßÎ ÐËÔÔÛÎÍ ‰ ײ¬»®³·¬¬»²¬ Ü«¬§ òòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÝÑÓÐÎÛÍÍÑÎÍÝ»²¬®·º«¹¿´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòðÝ»²¬®·¿¨·¿´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîëÔ±¾» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëλ½·°®±½¿¬·²¹ ‰ Ó«´¬·óݧ´·²¼»® òòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÝÑÒÊÛÇÑÎÍ ‰ Ô×ÙØÌ ÜËÌÇËÒ×ÚÑÎÓÔÇ ÚÛÜß°®±²ô Þ«½µ»¬ô ݸ¿·²ô Ú´·¹¸¬ô ͽ®»© òòòòòòòòòòòòòòòòòòòòò ïòîëß»³¾´§ô Þ»´¬ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòðѪ»² òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÝÑÒÊÛÇÑÎÍ ‰ ØÛßÊÇ ÜËÌÇÒÑÌ ËÒ×ÚÑÎÓÔÇ ÚÛÜß°®±²ô Þ«½µ»¬ô ݸ¿·²ô Ú´·¹¸¬ô Ѫ»² òòòòòòòòòòòòòòòòòòòòòòò ïòëß»³¾´§ô Þ»´¬ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîëλ½·°®±½¿¬·²¹ô ͸¿µ»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòëÝÎßÒÛÍ ßÒÜ ØÑ×ÍÌÍ øÒÑÌÛ ï ¿²¼ î÷Ó¿·² ¸±·¬ô 못®·²¹ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòë͵·° ر·¬ô Ì®±´´»§ ú Þ®·¼¹» Ü®·ª» òòòòòòòòòòòòòòòòòòòòòò îòðÍ´±°» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÝÎËÍØÛÎÍÑ®»ô ͬ±²» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò íòðÜÎÛÜÙÛÍÝ¿¾´» λ»´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëݱ²ª»§±® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÝ«¬¬»® Ø»¿¼ Ö·¹ Ü®·ª» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòëÓ¿²»«ª»®·²¹ É·²½¸» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëЫ³° òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëͽ®»»² Ü®·ª» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëͬ¿½µ»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëˬ·´·¬§ É·²½¸» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÛÔÛÊßÌÑÎÍ øÒÑÌÛ î÷Þ«½µ»¬ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëÝ»²¬®·º«¹¿´ ú Ù®¿ª·¬§ Ü·½¸¿®¹» òòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÛ½¿´¿¬±® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÚ®»·¹¸¬ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòëÚßÒÍÝ»²¬®·º«¹¿´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòðݱ±´·²¹ ̱©»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÚ±®½»¼ Ü®¿º¬ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëײ¼«½»¼ Ü®¿º¬ ©·¬¸±«¬ Ü¿³°»®Ý±²¬®±´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÚÛÛÜÛÎÍß°®±²ô Þ»´¬ô Ü·½ô ͽ®»© òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîëλ½·°®±½¿¬·²¹ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòȩ̈°·½¿´ß°°´·½¿¬·±²Í»®ª·½»Ú¿½¬±®ÙÛÒÛÎßÌÑÎÍ ‰øÒ±¬ É»´¼·²¹÷ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòðØßÓÓÛÎ Ó×ÔÔÍ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÔßËÒÜÎÇ ÉßÍØÛÎÍ ‰Î»ª»®·²¹ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÔßËÒÜÎÇ ÌËÓÞÔÛÎÍ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÔ×ÒÛ ÍØßÚÌ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÔËÓÞÛÎ ×ÒÜËÍÌÎÇÞ¿®µ»® ‰ Ü®«³ ̧°» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÛ¼¹»® Ú»»¼ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÔ·ª» α´´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÔ±¹ Ø¿«´ ‰ ײ½´·²» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÔ±¹ Ø¿«´ ‰ É»´´ ¬§°» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðѺº Þ»¿®·²¹ α´´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðд¿²»® Ú»»¼ ݸ¿·² òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëд¿²»® Ú´±±® ݸ¿·² òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëд¿²»® Ì·´¬·²¹ ر·¬ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëÍ´¿¾ ݱ²ª»§±® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëͱ®¬·²¹ Ì¿¾´» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÌ®·³³»® Ú»»¼ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëÓßÎ×ÒÛ ÐÎÑÐËÔÍ×ÑÒÓ¿·² Ü®·ª» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÓßÝØ×ÒÛ ÌÑÑÔÍÞ»²¼·²¹ α´´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðд¿¬» д¿²»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëЫ²½¸ Ю» ‰ Ù»¿® Ü®·ª»² òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÌ¿°°·²¹ Ó¿½¸·²» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòëѬ¸»® Ó¿½¸·²» ̱±´Ó¿·² Ü®·ª» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëß«¨·´·¿®§ Ü®·ª» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîëÓÛÌßÔ Ó×ÔÔÍÜ®¿© Þ»²½¸ ‰ Ý¿®®·¿¹» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÜ®¿© Þ»²½¸ ‰ Ó¿·² Ü®·ª» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÚ±®³·²¹ Ó¿½¸·²» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÍ´·¬¬»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÌ¿¾´» ݱ²ª»§±®Ò±²ó못®·²¹ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòîë못®·²¹ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòëÉ·®» Ü®¿©·²¹ ú Ú´¿¬¬»²·²¹ Ó¿½¸·²» òòòòòòòòòòòòòòòòòòòòòòòò îòðÉ·®» É·²¼·²¹ Ó¿½¸·²» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëÓÛÌßÔ ÎÑÔÔ×ÒÙ Ó×ÔÔÍ øÒÑÌÛ ï÷Þ´±±³·²¹ Ó·´´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò öݱ·´»®ô ¸±¬ ³·´´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðݱ·´»®ô ½±´¼ ³·´´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîëݱ´¼ Ó·´´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðݱ±´·²¹ Þ»¼ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëܱ±® Ñ°»²»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÜ®¿© Þ»²½¸» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÛ¼¹»® Ü®·ª» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëÚ»»¼ α´´ô 못®·²¹ Ó·´´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò íòëÚ«®²¿½» Ы¸»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòëر¬ Ó·´´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò íòðײ¹±¬ Ý¿® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòëÕ·½µó±«¬ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòëÓ¿²·°«´¿¬±® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò íòðÓ»®½¸¿²¬ Ó·´´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò íòðз»®½»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò íòðЫ¸»® ο³ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòëλ»´ Ü®·ª» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëλ»´ Ü®«³ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðλ»´»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò íòðα¼ ¿²¼ Þ¿® Ó·´´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëα«¹¸·²¹ Ó·´´ Ü»´·ª»®§ Ì¿¾´» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò íòðΫ²±«¬ Ì¿¾´»Î»ª»®·²¹ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò íòðÒ±²ó못®·²¹ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÍ¿©ô ¸±¬ ú ½±´¼ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòëͽ®»©¼±©² Ü®·ª» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò íòð͵»´° Ó·´´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò íòðÍ´·¬¬»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò íòðÍ´¿¾¾·²¹ Ó·´´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò íòðͱ¿µ·²¹ з¬ ݱª»® Ü®·ª» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò íòðͬ®¿·¹¸¬»²»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòëÌ¿¾´»ô ¬®¿²º»® ú ®«²±«¬ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòð̸®«¬ Þ´±½µ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò íòðÌ®¿½¬·±² Ü®·ª» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò íòðÌ«¾» ݱ²ª»§±® α´´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòë˲½®¿³¾´»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòëÉ·®» Ü®¿©·²¹ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÓ×ÔÔÍô ÎÑÌßÎÇ ÌÇÐÛÞ¿´´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòîëÜ®§»® ú ݱ±´»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðØ¿³³»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëÕ·´² òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòð̧°·½¿´ß°°´·½¿¬·±²Í»®ª·½»Ú¿½¬±®Ð»¾¾´» ú α¼ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðЫ¹ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëÌ«³¾´·²¹ Þ¿®®»´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÓ×ÈÛÎÍݱ²½®»¬» Ó·¨»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëÜ®«³ ̧°» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÑ×Ô ×ÒÜËÍÌÎÇݸ·´´»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîëп®¿ºº·² Ú·´¬»® Ю» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëÐßÐÛÎ Ó×ÔÔÍÞ¿®µ»® ß«¨·´·¿®·»ô ا¼®¿«´·½ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÞ¿®µ»®ô Ó»½¸¿²·½¿´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÞ¿®µ·²¹ Ü®«³ Í°«® Ù»¿® Ѳ´§ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòîëÞ»¿¬»® ú Ы´°»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëÞ´»¿½¸»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòðÝ¿´»²¼»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðݸ·°°»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòëݱ¿¬»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòðݱ²ª»®¬·²¹ Ó¿½¸·²»ô»¨½»°¬ Ý«¬¬»®ô д¿¬»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëݱ«½¸ α´´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëÝ«¬¬»®ô д¿¬»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðݧ´·²¼»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëÜ·½ λº·²»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëÜ®§»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëÚ»´¬ ͬ®»¬½¸»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîëÚ»´¬ ɸ·°°»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÖ±®¼¿² òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëÔ·²» ͸¿º¬ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÔ±¹ Ø¿«´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðЫ´° Ù®·²¼»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëЮ» α´´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðλ»´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëͬ±½µ ݸ»¬ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÍ«½¬·±² α´´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëÉ¿¸»® ú ̸·½µ»²»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÉ·²¼»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÐÎ×ÒÌ×ÒÙ ÐÎÛÍÍÛÍ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÐËÔÔÛÎÍ ‰ Þ¿®¹» Ø¿«´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÐËÓÐÍÝ»²¬®·º«¹¿´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòðÞ±·´»® Ú»»¼ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëλ½·°®±½¿¬·²¹Í·²¹´» ß½¬·²¹ï ±® î ݧ´·²¼»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòîëí ±® ³±®» ݧ´·²¼»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëܱ«¾´» ß½¬·²¹ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðન®§ô Ù»¿®ô Ô±¾»ô Ê¿²» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÎËÞÞÛÎ ×ÒÜËÍÌÎÇÓ·¨»® ‰ Þ¿²¾«®§ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòëΫ¾¾»® Ý¿´»²¼¿® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðΫ¾¾»® Ó·´´ øî ±® ³±®»÷ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòîë͸»»¬»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÌ·®» Þ«·´¼·²¹ Ó¿½¸·²» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòëÌ·®» ú Ì«¾» Ю» Ñ°»²»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòðÌ«¾»® ú ͬ®¿·²»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðÍÝÎÛÛÒÍß·® É¿¸·²¹ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòðÙ®·¦¦´§ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòðન®§ ‰ ͬ±²» ±® Ù®¿ª»´ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÌ®¿ª»´·²¹ É¿¬»® ײ¬¿µ» òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîëÊ·¾®¿¬·²¹ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò îòëÍÛÉßÙÛ Ü×ÍÐÑÍßÔ ÛÏË×ÐÓÛÒÌÞ¿® ͽ®»»² òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîëݸ»³·½¿´ Ú»»¼»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîëݱ´´»½¬±®ô Ý·®½«´·²» ±® ͬ®¿·¹¸¬´·²» òòòòòòòòòòòòòòòòòòòòòòòòò ïòîëÜ»©¿¬»®·²¹ ͽ®»»² òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîëÙ®·¬ ݱ´´»½¬±® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîëͽ«³ Þ®»¿µ»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîëÍ´±© ±® ο°·¼ Ó·¨»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîëÍ´«¼¹» ݱ´´»½¬±® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîë̸·½µ»²»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîëÊ¿½««³ Ú·´¬»® òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòîëÍÌÛÛÎ×ÒÙ ÙÛßÎ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòðÍÌÑÕÛÎÍ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòðÉ×ÒÝØ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòëÉ×ÒÜÔßÍÍ òòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòòò ïòéëö λº»® ¬± ÕÑÐóÚÔÛÈÒÑÌÛÍøï÷ Ó¿¨·³«³ ̱®¯«» ¿¬ ¬¸» ½±«°´·²¹ ³«¬ ²±¬ »¨½»»¼Î¿¬»¼ ̱®¯«» ±º ¬¸» ½±«°´·²¹òøî÷ ݸ»½µ ´±½¿´ ¿²¼ ·²¼«¬®·¿´ ¿º»¬§ ½±¼»òïíî

ïòîòÍ»´»½¬ ݱ«°´·²¹ Þ¿»¼ ±² Þ±®» Ý¿°¿½·¬§òÍ»´»½¬ ¬¸» ½±«°´·²¹ ·¦» ¬¸¿¬ ¸¿ ¿ ³¿¨·³«³ ¾±®»½¿°¿½·¬§ »¯«¿´ ¬± ±® ´¿®¹»® ¬¸¿² ¬¸» ´¿®¹»® ±º ¬¸» ¬©±¸¿º¬ò Ú±® ·²¬»®º»®»²½» º·¬ ´¿®¹»® ¬¸¿² ßÙÓ߬¿²¼¿®¼ô ½±²«´¬ ÕÑÐóÚÔÛÈòÊ»®·º§ ݱ«°´·²¹ Í·¦» Þ¿»¼ ±² Ô±¿¼ ο¬·²¹ò¿ò Í»´»½¬ ¿°°®±°®·¿¬» Í»®ª·½» Ú¿½¬±® º®±³ ¬¸» Ì¿¾´» ±²°¿¹» ïíîò¾ò Ý¿´½«´¿¬» ®»¯«·®»¼ ØÐ ñ ïðð ÎÐÓæØÐ ¨ Í»®ª·½» Ú¿½¬±® ¨ ïððã ØÐ ñ ïðð ÎÐÓÎÐÓ½ò Ê»®·º§ ¬¸¿¬ ¬¸» »´»½¬»¼ ½±«°´·²¹ ¸¿ ¿ ®¿¬·²¹¹®»¿¬»® ¬¸¿² ±® »¯«¿´ ¬± ¬¸» ®»¯«·®»¼ ØÐ ñ ïððÎÐÓòíòÚßÍÌŽÍ r Ù»¿® ݱ«°´·²¹Í»´»½¬·±² Ю±½»¼«®»Ý¸»½µ Þ¿´¿²½» λ¯«·®»³»²¬òݱ²«´¬ ܧ²¿³·½ Þ¿´¿²½·²¹ Ù«·¼» ¬± ¸»´° ¼»¬»®³·²» ·º¾¿´¿²½·²¹ · ®»¯«·®»¼ò Ê»®·º§ ¬¸¿¬ ¬¸» ³¿¨·³«³ ±°»®¿¬·²¹°»»¼ ¼±» ²±¬ »¨½»»¼ ¬¸» ³¿¨·³«³ °»»¼ ®¿¬·²¹ ±º ¬¸»½±«°´·²¹ò ̸» ³¿¨·³«³ °»»¼ ®¿¬·²¹ ¼±» ²±¬ ½±²·¼»®´¿¬»®¿´ ½®·¬·½¿´ °»»¼ ½±²·¼»®¿¬·±² º±® º´±¿¬·²¹ ¸¿º¬¿°°´·½¿¬·±²òÒ±¬»æ Ý¿®» ³«¬ ¾» »¨»®½·»¼ ±² °®±°»® »´»½¬·±² ±º ¿²§¸¿º¬ ½±«°´·²¹ò ̸» Ë»® ³«¬ ¿«®» ¬¸»³»´ª»¬¸¿¬ ¬¸» ¼»·¹² ±º ¬¸» ¸¿º¬ ¬± ½±«°´·²¹ ¸«¾½±²²»½¬·±² · ¿¼»¯«¿¬» º±® ¬¸» ¼«¬§ ·²¬»²¼»¼òܧ²¿³·½ Þ¿´¿²½·²¹ Ù«·¼»Þ¿´¿²½·²¹ ®»¯«·®»³»²¬ º±® ¿ ½±«°´·²¹ ¿®» ¼»°»²¼»²¬ ±²º¿½¬±® ¼»¬»®³·²»¼ ¾§ ¬¸» ½¸¿®¿½¬»®·¬·½ ±º ¬¸» ½±²²»½¬»¼»¯«·°³»²¬ò Ú±® ¬¸· ®»¿±²ô ¬¸» Þ¿´¿²½·²¹ ݸ¿®¬ ¸±«´¼ ¾»«»¼ ¿ ¿ ÙË×ÜÛ ÑÒÔÇ ¬± ¿·¬ ·² ¼»¬»®³·²·²¹ ©¸»¬¸»® ±®²±¬ ¾¿´¿²½·²¹ · ®»¯«·®»¼ò̸» Þ¿´¿²½·²¹ ݸ¿®¬ ¸±©² ¿®» ¾¿»¼ ±² ßÙÓß çðððóÝçð «¹¹»¬»¼ ¾¿´¿²½» ½´¿» º±® §¬»³ ©·¬¸ ߪ»®¿¹»Œ»²·¬·ª·¬§ ¬± «²¾¿´¿²½»ò Ú±® §¬»³ ©·¬¸ ¸·¹¸»® »²·¬·ª·¬§¬± «²¾¿´¿²½»ô ¾¿´¿²½·²¹ ±º ¬¸» ½±«°´·²¹ ³¿§ ¾» ®»¯«·®»¼ ¿¬´±©»® °»»¼ò Ú±® §¬»³ ©¸·½¸ ¿®» ´» »²·¬·ª» ¬± «²ó¾¿´¿²½»ô ½±«°´·²¹ ³¿§ ¾» ¿¾´» ¬± ±°»®¿¬» ¿¬ ¸·¹¸»® °»»¼¬¸¿² ¬¸±» ¸±©² ¿¬ ´±©»® ¾¿´¿²½» ´»ª»´ò ̸»®»º±®»ô ·² ¬¸»¿¾»²½» ±º »·¬¸»® ¿ ¬¸±®±«¹¸ §¬»³ ¿²¿´§· ±® °¿¬ «»®»¨°»®·»²½» ©·¬¸ ¿ ·³·´¿® ·²¬¿´´¿¬·±²ô ¬¸»» ½¸¿®¬ ¸±«´¼¾» «»¼ ¿ ¿ ÙË×ÜÛ ÑÒÔÇòÚßÍÌŽÍ r ¿²¼ ÍÛÎ×ÛÍ Ø ¹»¿® ½±«°´·²¹ ³¿§ ¾» ½±³°±²»²¬¾¿´¿²½»¼ô ±® ¿»³¾´§ ¾¿´¿²½»¼ ©·¬¸ º·¬¬»¼ ½±³°±²»²¬ø̧°»ÚÞ ¿²¼ ̧°» ØÞô ®»°»½¬·ª»´§÷òÉßÔÜÎÑÒ r ¹»¿® ½±«°´·²¹ ¿®» ¿ª¿·´¿¾´» ½±³°±²»²¬¾¿´¿²½»¼ ±²´§òÓ±¼»´ Þ ¹»¿® ½±«°´·²¹ ¿®» ²±¬ ¼»·¹²»¼ ¬± ¾» ¾¿´¿²½»¼ò̸»» ½¸¿®¬ ¿°°´§ ¬± ·¦» ï ¬¸®±«¹¸ é ±²´§ò ܧ²¿³·½¾¿´¿²½» ±º ·¦» è ¬¸®±«¹¸ í𠳫¬ ¾» ½±²·¼»®»¼ ±² ¿ ½¿»ó¾§ó½¿» ¾¿·ò ݱ²«´¬ ÕÑÐóÚÔÛÈ º±® ¿·¬¿²½»òïíí

ÚßÍÌŽÍ r Ù»¿® ݱ«°´·²¹Ú«´´ Ú´»¨ ݱ«°´·²¹ Í·¦» ï ïñîóéß ½±²ª»²¬·±²¿´ ì󾻿®·²¹ §¬»³ ¸¿ ¬©± ¾»¿®·²¹ ±² ¬¸»¼®·ª·²¹ ¸¿º¬ ¿²¼ ¬©± ¾»¿®·²¹ ±² ¬¸» ¼®·ª»² ¸¿º¬ò Þ±¬¸ ¿²¹«´¿®¿²¼ ±ºº»¬ ¸¿º¬ ³·¿´·¹²³»²¬ ©·´´ ¾» °®»»²¬ ¬± ±³» ¼»¹®»»¿²¼ ¿ º«´´ º´»¨ ½±«°´·²¹ · ³¿²¼¿¬±®§ò ̸» º«´´ º´»¨ ½±«°´·²¹ ·¬¸» ¬¿²¼¿®¼ ½±«°´·²¹ ¸¿ª·²¹ ¬©± ¹»¿® ®·²¹ »¬ô ±²» »¬ °»®¸¿´º ½±«°´·²¹ò Ú±® »´»½¬·±² °®±½»¼«®» »» °¿¹» ïííòݱ«°´·²¹ Ù®»¿»ÕÑÐóÚÔÛÈ ±ºº»® ¹®»¿» °»½·º·½¿´´§ ¼»·¹²»¼ º±® «» ·² ½±«°´·²¹¿°°´·½¿¬·±²ò Ú±® °®±°»® ´«¾®·½¿¬·±² ¿²¼ ´±²¹ »®ª·½» ´·º»ô «» ÕÍÙͬ¿²¼¿®¼ ݱ«°´·²¹ Ù®»¿»ô ±® ÕØÐ Ø·¹¸ л®º±®³¿²½» ݱ«°´·²¹Ù®»¿»ò Í»» °¿¹» îðìóîðê º±® ¼»¬¿·´»¼ °»½·º·½¿¬·±²òݱ«°´·²¹Í·¦»ï ïñîîî ïñîíí ïñîÓ¿¨·³«³Ó¿¨·³«³Þ±®» ©·¬¸Þ±®» ©·¬¸ λ¼«½»¼Í¬¿²¼¿®¼Î»¼«½»¼ Ü»°¬¸Õ»§©¿§Ü»°¬¸ Õ»§©¿§Õ»§©¿§ï ëñèï íñìíñè¨ ïñèî ïñèî ïñìïñî¨ íñïêî íñìí íñì¨ íñïêí ïñèí íñèéñè¨ ïñìí íñìì ï ¨ ëñïêο¬·²¹ØÐ ñ ïððÎÐÓîéëðçðïêðîíë̱®¯«»Î¿¬·²¹ø´¾òó·²ò÷ïéðððíïëððëêéððïðïðððïìèðððл¿µÌ±®¯«»Î¿¬·²¹ø´¾òó·²ò÷íìðððêíðððïïíìððîðîðððîçêðððÓ¿¨·³«³Í°»»¼øÎÐÓ÷ïîðððçíððéçððêèððêðððÉ»·¹¸¬©·¬¸ ͱ´·¼Ü·³»²·±²ßØ«¾ø´¾ò÷Þ Ý Û Ñïêòëê ì ïñèï ïëñïêî íñïêîéòìé ì ïëñïêïñèî éñïêî éñèìèòðè íñèê íñïêíñïêí ïñíîí ëñèéðòèç éñïêé ëñïêíñïêí ïçñíîì ïñìïïíïïè ïñîïñìì íñïêëì ì ïñìì ïñîï ¨ íñèíéëîíêðððìéîðððëîêðïééïîïñîì ïñî ì íñìë ïñèï ïñì ¨ éñïêëðëíïèðððêíêðððìééðîíïïíëñèë ë ïñîë éñèï ïñî ¨ éñïêéððììïðððèèîðððìíððíëïïëëñïêë ïñîö ë éñèê íñèï ïñî ¨ ïñîçîðëèððððïïêððððíèèðìíëïêíñìêöê ïñîé ï íñì ¨ ïñîïîðëéëçðððïëïèðððíêððëíèïèéöè è ïñîî ¨ ïñîïèìðïïêððððîíîððððíðððèêðîðíñìö Í·¦» ë ïñîô ê ¿²¼ é ¿®» ±²´§ ¿ª¿·´¿¾´» ©·¬¸ »¨°±»¼ ¾±´¬ ´»»ª»ò ̧°» ÛÞ »¨°±»¼ ¾±´¬ ¿®» ¬¿²¼¿®¼òç íñìïðïëñïêïîïñïêïíïíñïêïìïíñïêïéëñïêïñìëñïêëñïêëñïêëñïêíñèì íñìë ëñïêê ïñíîê îçñíîé ïíñíîè ïïñïêë íñìê ïñîé ëñïêèè ïíñïêïð ëñïêÌÇÐÛ ÛÞ óÛÈÐÑÍÛÜ ÞÑÔÌÍÌÇÐÛ ÍÞ óÍØÎÑËÜÛÜ ÞÑÔÌÍÚ¿¬»²»® Ü¿¬¿Ý±«°´·²¹Í·¦»Ï¬§òï ïñî è îî ê îî ïñî ê ìí è ìí ïñî è ȩ̀°» ÛÞÛ¨°±»¼ Þ±´¬Ì§°» ÍÞ͸®±«¼»¼ Þ±´¬Í·¦» ú Þ±´¬Í·¦» ú Þ±´¬Ô»²¹¬¸ Ý·®½´»Ï¬§òÔ»²¹¬¸ Ý·®½´»íñè¨ ì ïíñïêè íñè¨ ï ì ïíñïêïñî¨ î ïñ ë éñèïðíñè¨ ï ë ïíñïêëñè¨ î íñ é ïñèïðïñî¨ ï ëñïêéëñè¨ î íñ è ïñèïîïñî¨ ï ëñïêèíñì¨ í íñ ç ïñîïîëñè¨ ï ëñèç çñíîì è íñì¨ í íñèïïïìëñè¨ ï ëñèïð ëñèì ïñî ïðíñì¨ í íñèïîïìëñè¨ ï ëñèïï íñìë è éñè¨ ì ïñìïíïñîïìíñì¨ î ïñèïí íñïêë ïñîö ïìéñè¨ í ïñìïìïñîó ó óêöïìéñè¨ í ïñìïëíñìó ó óéöïêï ¨ í ëñèïèïñìó ó óö Í·¦» ýë ïñî ¿²¼ ´¿®¹»® ¿®» ¿ª¿·´¿¾´» ·² »¨°±»¼ ¾±´¬ ±²´§òïíì

Ú«´´ Ú´»¨ ݱ«°´·²¹ Í·¦» ïóíðݱ«°´·²¹ ̧°» ÛÞ øÛ¨°±»¼ Þ±´¬÷ ﮬ Ò«³¾»®Ý±«°´·²¹Í·¦»ï ïñîîî ïñîíí ïñîÚ«´´ Ú´»¨ ݱ«°´·²¹Ú ·²·¸Ò± Þ±®»É¬ò Þ±®»Ð¿®¬ Ò±òﮬ Ò± òï ïñîÚ ÛÞ ÚÚïçï ïñîÚ ÛÞ ÚÚ ÚÞîÚÛÞ ÚÚíðîÚÛÞ ÚÚ ÚÞî ïñîÚ ÛÞ ÚÚëîî ïñîÚ ÛÞ ÚÚ ÚÞíÚÛÞ ÚÚéêíÚÛÞ ÚÚ ÚÞí ïñîÚ ÛÞ ÚÚïïéí ïñîÚ ÛÞ ÚÚ ÚÞì ìÚÛÞ ÚÚïèðìÚÛÞ ÚÚ ÚÞì ÛÞ ÚÍë ìÚ ÛÞ ÍÔÛÛÊÛìïìÚÚØËÞìéìÚ ÚØËÞ ÚÞì ïñî ì ïñîÚ ÛÞ ÚÚîììì ïñîÚ ÛÞ ÚÚ ÚÞì ïñî ÛÞ ÚÍé ì ïñîÚ ÛÞ ÍÔÛÛÊÛëíì ïñîÚ ÚØËÞêêì ïñîÚ ÚØËÞ ÚÞë ëÚÛÞ ÚÚíêïëÚÛÞ ÚÚ ÚÞë ÛÞ ÚÍç ëÚÛÞ ÍÔÛÛÊÛèðëÚ ÚØËÞçêëÚ ÚØËÞ ÚÞë ïñî ë ïñîÚ ÛÞ ÚÚìîîë ïñîÚ ÛÞ ÚÚ ÚÞë ïñî ÛÞ ÚÍïìë ïñîÚ ÛÞ ÍÔÛÛÊÛèçë ïñîÚ ÚØËÞïïëë ïñîÚ ÚØËÞê êÚÛÞ ÚÚìçìêÚÛÞ ÚÚ ÚÞê ÛÞ ÚÍïìêÚÛÞ ÍÔÛÛÊÛïððêÚÚØËÞïìðêÚ ÚØËÞé éÚÛÞ ÚÚèîîéÚÛÞ ÚÚ ÚÞé ÛÞ ÚÍîîéÚÛÞ ÍÔÛÛÊÛïêðéÚÚØËÞîìðéÚ ÚØËÞß´´ º·²·¸ ¾±®» ¿²¼ µ»§©¿§ °»® ßÙÓß çððîóßèê ½±³³»®½·¿´ ¬¿²¼¿®¼ ¬±´»®¿²½» ©·¬¸ ·²¬»®º»®»²½» º·¬ ¾±®»ò Ý´»¿®¿²½» º·¬ ¾±®» ¿®» ¿ª¿·´¿¾´» ±² ®»¯«»¬ ¿²¼·²½´«¼» ±²» »¬½®»© ±ª»® µ»§©¿§òݱ«°´·²¹Í·¦»ï ïñîîî ïñîíí ïñîÚ«´´ Ú´»¨ ݱ«°´·²¹Ú·²·¸Ò± Þ±®»É¬ò Þ±®»Ð¿®¬ Ò±òﮬ Ò±òï ïñîÚ ÍÞ ÚÚïçï ïñîÚ ÍÞ ÚÚ ÚÞîÚÍÞ ÚÚíðîÚ ÍÞ ÚÚ ÚÞî ïñîÚ ÍÞ ÚÚëîî ïñîÚ ÍÞ ÚÚ ÚÞíÚÍÞ ÚÚéêíÚÍÞ ÚÚ ÚÞí ïñîÚ ÍÞ ÚÚïïéí ïñîÚ ÍÞ ÚÚ ÚÞп®¬Ò±òɬòÍ´»»ª»Ð¿®¬Ò± òɬ òï ïñî ÍÞ ÚÍï ï ïñîÚ ÍÞ ÍÔÛÛÊÛê Þî ÍÞ ÚÍï îÚÍÞ ÍÔÛÛÊÛè Þî ïñî ÍÞ ÚÍî î ïñîÚ ÍÞ ÍÔÛÛÊÛïíí ÍÞ ÚÍî íÚÍÞ ÍÔÛÛÊÛïëí ïñî ÍÞ ÚÍì í ïñîÚ ÍÞ ÍÔÛÛÊÛîêÚ´»¨ Ø« ¾Ú·²·¸Ò± Þ±®»É¬ò Þ±®»Ð¿®¬ Ò±òﮬ Ò±òï ïñîÚ ÚØË í ï ïñîÚ ÚØËÞ ÚÞîÚÚØË é îÚ ÚØËÞ ÚÞî ïñîÚ ÚØËÞïîî ïñîÚ ÚØËÞ ÚÞíÚÚØËÞîðíÚ ÚØËÞ ÚÞí ïñîÚ ÚØËÞîèí ïñîÚ ÚØËÞ ÚÞìì ïñîëìÚÍÞ ÚÚì ïñîÚ ÍÞ ÚÚëÚÍÞ ÚÚïèðîììíêïìÚ ÍÞ ÚÚ ÚÞì ïñîÚ ÍÞ ÚÚ ÚÞëÚÍÞ ÚÚ ÚÞì ÍÞ ÚÍì ìÚÍÞ ÍÔÛÛÊÛì ïñî ÍÞ ÚÍì ì ïñîÚ ÍÞ ÍÔÛÛÊÛë ÍÞ ÚÍé ëÚÍÞ ÍÔÛÛÊÛݱ«°´·²¹ ̧°» ÍÞ ø͸®±«¼»¼ Þ±´¬÷ ﮬ Ò«³¾»®ß´´º·²·¸ ¾±®» ¿²¼ µ»§©¿§ °»® ßÙÓß çððîóßèê ½±³³»®½·¿´ ¬¿²¼¿®¼ ¬±´»®¿²½» ©·¬¸ ·²¬»®º»®»²½» º·¬ ¾±®»ò Ý´»¿®¿²½» º·¬ ¾±®» ¿®» ¿ª¿·´¿¾´» ±² ®»¯«»¬¿²¼ ·²½´«¼» ±²» »¬½®»© ±ª»® µ»§©¿§òíéëðéîìÚÚØËÞì ïñîÚ ÚØËÞëÚÚØËÞìéêêçêìÚ ÚØËÞ ÚÞì ïñîÚ ÚØËÞ ÚÞëÚ ÚØËÞ ÚÞݱ«°´·²¹ ̧°» øÛ¨°±»¼ Þ±´¬÷ ﮬ Ò«³¾»®Ý±«°´·²¹Í·¦»èçïðïïïîÚ«´´ Ú´»¨èÚÛÞ ÚÚçÚÛÞ ÚÚïðÚÛÞ ÚÚïïÚÛÞ ÚÚïîÚÛÞ ÚÚÓ¿´» Ø¿´º©ñß½½»èÚÛÞ ÓØçÚÛÞ ÓØïðÚÛÞ ÓØïïÚ ÛÞ ÓØïîÚ ÛÞ ÓØÚ»³¿´» Ø¿´º©ñß½½»èÚÛÞ ÚØçÚÛÞ ÚØïðÚ ÛÞ ÚØïïÚ ÛÞ ÚØïîÚ ÛÞ ÚØØ «¾ Ó ¿´» Í´»»ª » Ú »³¿´» Í´»»ª » Û²¼ η² ¹èÚÚØËÞçÚÚØËÞïðÚ ÚØËÞïïÚ ÚØËÞïîÚÚØËÞèÚÛÞ ÓÍÔÛÛÊÛèÚÛÞ ÚÍÔÛÛÊÛçÚÛÞ ÓÍÔÛÛÊÛçÚÛÞ ÚÍÔÛÛÊÛïðÚÛÞ ÓÍÔÛÛÊÛïðÚÛÞ ÚÍÔÛÛÊÛïïÚÛÞ ÓÍÔÛÛÊÛïïÚÛÞ ÚÍÔÛÛÊÛïîÚÛÞ ÓÍÔÛÛÊÛïîÚÛÞ ÚÍÔÛÛÊÛèÚÛÎ×ÒÙçÚÛÎ×ÒÙïðÚÛÎ×ÒÙïïÚ ÛÎ×ÒÙïîÚ ÛÎ×ÒÙÚßÍÌŽÍ r Ù»¿® ݱ«°´·²¹Ú¿¬»²»® Í»¬øײ½´«¼» Ù¿µ»¬÷Í´»»ª»Ú´»¨ Ø« ¾Ð¿®¬Ò±ò ɬò п®¬Ò± ò ɬ òÚ ·²·¸Ò± Þ±®»É¬ò Þ±®»Ð¿®¬ Ò±òﮬ Ò± òï ïñî ÛÞ ÚÍï ï ïñîÚ ÛÞ ÍÔÛÛÊÛê ï ïñîÚ ÚØËÞí ï ïñîÚ ÚØËÞ ÚÞî ÛÞ ÚÍï îÚ ÛÞ ÍÔÛÛÊÛè îÚÚØËÞé îÚ ÚØËÞ ÚÞî ïñî ÛÞ ÚÍî î ïñîÚ ÛÞ ÍÔÛÛÊÛïìî ïñîÚ ÚØËÞïîî ïñîÚ ÚØËÞ ÚÞí ÛÞ ÚÍí íÚÛÞ ÍÔÛÛÊÛïéíÚÚØËÞîðíÚ ÚØËÞ ÚÞí ïñî ÛÞ ÚÍë í ïñîÚ ÛÞ ÍÔÛÛÊÛîèí ïñîÚ ÚØËÞîèí ïñîÚ ÚØËÞ ÚÞÚ¿¬»²»® Í»¬øײ½´«¼» Ù¿µ»¬÷Ý»²¬»® Ú´¿²¹»Ú¿¬»²»® Í»¬Û²¼ η²¹Ú¿¬»²»® Í»¬ø·²½´«¼» ¹¿µ»¬÷ ø·²½´«¼» ¹¿µ»¬÷è ÛÞ ÚÍè ÛÎÚÍç ÛÞ ÚÍç ÛÎÚÍïðÛÞ ÚÍïð ÛÎÚÍïïÛÞ ÚÍïï ÛÎÚÍïîÛÞ ÚÍïî ÛÎÚÍïíïìïëïêïèïíÚÛÞ ÚÚïìÚ ÛÞ ÚÚïëÚ ÛÞ ÚÚïêÚ ÛÞ ÚÚïèÚ ÛÞ ÚÚïíÚ ÛÞ ÓØïìÚ ÛÞ ÓØïëÚ ÛÞ ÓØïêÚ ÛÞ ÓØïèÚÛÞ ÓØïíÚ ÛÞ ÚØïìÚ ÛÞ ÚØïëÚ ÛÞ ÚØïêÚÛÞ ÚØïèÚÛÞ ÚØïíÚÚØËÞïìÚÚØËÞïëÚÚØËÞïêÚÚØËÞïèÚÚØËÞïíÚÛÞ ÓÍÔÛÛÊÛïíÚÛÞ ÚÍÔÛÛÊÛïìÚÛÞ ÓÍÔÛÛÊÛïìÚÛÞ ÚÍÔÛÛÊÛïëÚÛÞ ÓÍÔÛÛÊÛïëÚÛÞ ÚÍÔÛÛÊÛïêÚÛÞ ÓÍÔÛÛÊÛïêÚ ÛÞ ÚÍÔÛÛÊÛïèÚÛÞ ÓÍÔÛÛÊÛïèÚ ÛÞ ÚÍÔÛÛÊÛïíÚ ÛÎ×ÒÙïìÚ ÛÎ×ÒÙïëÚ ÛÎ×ÒÙïêÚ ÛÎ×ÒÙïèÚÛÎ×ÒÙïíÛÞ ÚÍïìÛÞ ÚÍïëÛÞ ÚÍïêÛÞ ÚÍïèÛÞ ÚÍïí ÛÎÚÍïì ÛÎÚÍïë ÛÎÚÍïê ÛÎÚÍïè ÛÎÚÍîðîîîìîêîèíðîðÚÛÞ ÚÚîîÚÛÞ ÚÚîìÚ ÛÞ ÚÚîêÚ ÛÞ ÚÚîèÚ ÛÞ ÚÚíðÚÛÞ ÚÚîðÚ ÛÞ ÓØîîÚ ÛÞ ÓØîìÚ ÛÞ ÓØîêÚ ÛÞ ÓØîèÚ ÛÞ ÓØíðÚÛÞ ÓØîðÚ ÛÞ ÚØîîÚ ÛÞ ÚØîìÚ ÛÞ ÚØîêÚ ÛÞ ÚØîèÚÛÞ ÚØíðÚÛÞ ÚØîðÚÚØËÞîîÚÚØËÞîìÚÚØËÞîêÚÚØËÞîèÚÚØËÞíðÚÚØËÞîðÚÛÞ ÓÍÔÛÛÊÛîðÚÛÞ ÚÍÔÛÛÊÛîîÚÛÞ ÓÍÔÛÛÊÛîîÚÛÞ ÚÍÔÛÛÊÛîìÚÛÞ ÓÍÔÛÛÊÛîìÚÛÞ ÚÍÔÛÛÊÛîêÚÛÞ ÓÍÔÛÛÊÛîêÚÛÞ ÚÍÔÛÛÊÛîèÚÛÞ ÓÍÔÛÛÊÛîèÚ ÛÞ ÚÍÔÛÛÊÛíðÚ ÛÞ ÓÍÔÛÛÊÛíðÚÛÞ ÚÍÔÛÛÊÛîðÚ ÛÎ×ÒÙîîÚ ÛÎ×ÒÙîìÚ ÛÎ×ÒÙîêÚ ÛÎ×ÒÙîèÚ ÛÎ×ÒÙíðÚÛÎ×ÒÙîðÛÞ ÚÍîîÛÞ ÚÍîìÛÞ ÚÍîêÛÞ ÚÍîèÛÞ ÚÍíðÛÞ ÚÍîð ÛÎÚÍîî ÛÎÚÍîì ÛÎÚÍîê ÛÎÚÍîè ÛÎÚÍíð ÛÎÚÍïíê

ÎÌÜ ß»³¾´·»ÎÌÜ ß»³¾´·» ©·¬¸ Ì»®³·²¿´ ػͰ®·²¹ó´±¿¼»¼ ¿»³¾´·» ¿®» «»¼ ¬± ³¿·²¬¿·² °±·¬·ª» ½±²¬¿½¬ ¾»¬©»»² ¬¸»»²±® ¬·° ¿²¼ ¬¸» «®º¿½» ¬± ¾» ³±²·¬±®»¼ô ¬§°·½¿´´§ «»¼ ©·¬¸ ¬¸»®³±©»´´¿»³¾´·»ò ݱ²¿¨ Þ«ºº¿´± «°°´·» ¿ ²«³¾»® ±º ¬§´» ±º °®·²¹ó´±¿¼»¼¿»³¾´·» ¬± ³»»¬ ¿°°´·½¿¬·±² ²»»¼ò Í°®·²¹ó´±¿¼»¼ ¿»³¾´·» ½¿² ¾»°®±ª·¼»¼ ©·¬¸ ¿´´ ¬»®³·²¿´ ¸»¿¼ò ײ ¿¼¼·¬·±²ô ¬¸» ÌïïÍÔ ³±¼»´ °®±ª·¼» ¿°®·²¹ó´±¿¼»¼ ¿»³¾´§ ¾«·´¬ ·²¬± ¬¸» Ìïï ¿´«³·²«³ ¬»®³·²¿´ ¸»¿¼ò ̸·¿´´±© ½±³°´»¬» ¼·¿»³¾´§ ¿²¼ ®»³±ª¿´ ±º ¬¸» »²±® °®±¾» ©·¬¸±«¬¼·³¿²¬´·²¹ ¬¸» ¬»®³·²¿´ ¸»¿¼ º®±³ ¬¸» ½±²¼«·¬ ±® ¬¸» ª»»´ò Ú±® ¼»¬¿·´»¼·²º±®³¿¬·±² ±² ¬¸»» ³±«²¬·²¹ ¬§´»ô »» °¿¹» ììóìëòÎÌÜìí É í íïêÍÍ îëÎÌÜìí д¿¬·²«³ïððã ðòððíèë ñÓÎÌÜÚìí д¿¬·²«³ïððã ðòððíèë ñÎÌÜìì д¿¬·²«³ïððã ðòððíèë ñײ½±²»´ êð𠸻¿¬¸¬¿²¼¿®¼ÎÌÜìë д¿¬·²«³ïððã ðòððíçïêÎÌÜèê д¿¬·²«³îððã ðòððíèë ñÓÎÌÜÚìíð д¿¬·²«³ïðððã ðòððíèë ñߪ¿·´¿¾´» ©·¬¸ ðòîëðþ¸»¿¬¸ ¼·¿³»¬»® ±® ´¿®¹»®ñÉ øÝ´¿ Þ÷ߪ¿·´¿¾´» º±® ÎÌÜìíô ìì ¿²¼ìëô ·²¹´» ¿²¼ ¼«¿´å ¿²¼ ÎÌÜèêôÓÎÌÜÚìí ¿²¼ ÓÎÌÜÚìíðô·²¹´» ±²´§Ê øïñí Ý´¿ Þ÷ߪ¿·´¿¾´» º±® ÎÌÜìíô ìì ¿²¼ìë ·²¹´» ±²´§Í øÝ´¿ ß÷ߪ¿·´¿¾´» º±® ÎÌÜìíô ìì ¿²¼ ìë·²¹´» ±²´§ÈÛÎÌÜìï ݱ°°»®ïð øçòðëã ðòððìîê ñߪ¿·´¿¾´» º±® ÛÎÌÜìïô ·²¹´» ±²´§åߪ¿·´¿¾´» º±® ÛÎÌÜìîô ·²¹´»åߪ¿·´¿¾´» º±® ÛÎÌÜìîô ¼«¿´åߪ¿·´¿¾´» ©·¬¸ ðòîëðþ¸»¿¬¸ ¼·¿³»¬»® ±® ´¿®¹»®ÛÎÌÜìî Ò·½µ»´ïîðã ðòððêéî ñߪ¿·´¿¾´» ©·¬¸ ðòîëðþ¸»¿¬¸ ¼·¿³»¬»® ±® ´¿®¹»®îíìêéèÎÛÜÉØ×ÌÛÎÛÜÎÛÜÉØ×ÌÛÎÛÜÎÛÜÉØ×ÌÛÉØ×ÌÛÎÛÜÎÛÜÉØ×ÌÛÉØ×ÌÛÎÛÜÎÛÜÎÛÜÎÛÜÉØ×ÌÛÉØ×ÌÛÎÛÜÎÛÜÎÛÜÎÛÜÉØ×ÌÛÉØ×ÌÛÉØ×ÌÛÉØ×ÌÛîóÉ×ÎÛÍ×ÒÙÔÛíóÉ×ÎÛÍ×ÒÙÔÛìóÉ×ÎÛÍ×ÒÙÔÛîóÉ×ÎÛÜËßÔíóÉ×ÎÛÜËßÔìóÉ×ÎÛÜËßÔíðì ͬ¿·²´» ͬ»»´ÍÍïîðòïîëþ ¼·¿³»¬»®ÍÍïèðòïèéþ ¼·¿³»¬»®ÍÍîëðòîëðþ ¼·¿³»¬»®íïê ͬ¿·²´» ͬ»»´íïêÍÍïîðòïîëþ ¼·¿³»¬»®íïêÍÍïèðòïèéþ ¼·¿³»¬»®íïêÍÍîëðòîëðþ ¼·¿³»¬»®×²½±²»´ êðð×ÒÝïîðòïîëþ ¼·¿³»¬»®Í¬¿²¼¿®¼ ¸»¿¬¸³¿¬»®·¿´ º±® ÎÌÜìì×ÒÝïèðòïèéþ ¼·¿³»¬»®Í¬¿²¼¿®¼ ¸»¿¬¸³¿¬»®·¿´ º±® ÎÌÜìì×ÒÝîëðòîëðþ ¼·¿³»¬»®Í¬¿²¼¿®¼ ¸»¿¬¸³¿¬»®·¿´ º±® ÎÌÜììïî

¿¼ ¿²¼ Í°®·²¹óÔ±¿¼»¼ Ó±«²¬·²¹ÎÌÜ ß»³¾´·»Ð®±¹®»·ª» Ü»½®·°¬·±² Û¨¿³°´»æÌëÝ×ÍÔßÒÍéÌïïÍÔÌïïÝÍÔÉÉ»¿¬¸»® °®±±ºß´«³·²«³ ½±²¬®«½¬·±²Þ«·´¬ó·² °®·²¹ ´±¿¼»¼ ¿»³¾´§Ý±²¼«·¬ °±®¬ ïñî ÒÐÌÌëßÔó ß´«³·²«³ÌëÝ× ó Ý¿¬ ×®±²ÒÛÓß ì ®¿¬»¼Ý±²¼«·¬ °±®¬ íñì ÒÐÌÌëÍÍÒÛÓß ìÈ ®¿¬»¼íïê ¬¿·²´» ¬»»´ ½±²¬®«½¬·±²Ý±²¼«·¬ °±®¬ íñì ÒÐÌÌéÉ»¿¬¸»® °®±±ºß´«³·²«³ ½±²¼«·¬ ¾±¨¿½½±³³±¼¿¬» «° ¬± è ¬»®³·²¿´Ý±²¼«·¬ °±®¬ íñì ÒÐÌÌèÉ»¿¬¸»® °®±±ºÝ¿¬ ·®±² ½±²¬®«½¬·±²Þ´¿½µ »°±¨§ ½±¿¬»¼ øÛ󽱿¬÷ݱ²¼«·¬ °±®¬ íñì ÒÐÌÌèÛÛ¨°´±·±² °®±±º ®¿¬·²¹ Ý´¿ ×ôÙ®±«° Þô Ý ú Ü Ý´¿ ××ôÙ®±«° Ûô Ú ú Ù Ý´¿ ×××Ù®¿§ ·®±² ¾±¼§ ©·¬¸ ¿´«³·²«³½®»© ½±ª»®ÒÛÓß ì ®¿¬»¼Ý±²¼«·¬ °±®¬ ïñî ÒÐÌÉ»¿¬¸»® °®±±ºß´«³·²«³ ½±²¬®«½¬·±²Ý±²¼«·¬ °±®¬ ïñî ÒÐÌÌïïÐÔÉ»¿¬¸»® °®±±ºÐ´¿¬·½ ½±²¬®«½¬·±²Ý±²¼«·¬ °±®¬ ïñî ÒÐÍÓÌïîÉ»¿¬¸»® °®±±ºß´«³·²«³ ½±²¬®«½¬·±²Ú´·°ó¬±° ¸»¿¼Ý±²¼«·¬ °±®¬ ïñî ÒÐÌÌïíÌÚÜß ½±³°´·¿²¬ô ÒÛÓß ìÈ ®¿¬»¼É¸·¬»ô «²°·¹³»²¬»¼ °±´§°®±°§´»²»½±²¬®«½¬·±²ì ¬»®³·²¿´ °±¬Ý±²¼«·¬ °±®¬ íñì ÒÐÌÌïëÛßÔ ó ß´«³·²«³ÌïëÛÍÍ ó ͬ¿·²´»Í¬»»´Û¨°´±·±² Ю±±º ®¿¬·²¹ Ý´¿ ïôÜ·ª··±² ïô Ù®±«° Þô Ý ¿²¼ Ü ¿²¼Ü«¬ Ю±±ºñ×¹²·¬·±² Ю±±º ®¿¬·²¹ º±®Ý´¿ ××ô Ü·ª··±² ïô Ù®±«° Ûô Ú ú Ùο¬·²¹æ ÌïëÛßÔ › ÒÛÓß ìôÌïëÛÍÍ › ÒÛÓß ìÈݱ²¼«·¬ °±®¬ íñì ÒÐÌÚ±® ðòïîëþô ðòïèéþ ¿²¼ðòîëðþ ¼·¿³»¬»® ¸»¿¬¸Í¬¿·²´» ¬»»´ ½±²¬®«½¬·±²Ó±«²¬·²¹ ¬¸®»¿¼ ïñî ÒÐÌÍÔßÒÚ±® ðòïîëþô ðòïèéþ ¿²¼ðòîëðþ ¼·¿³»¬»® ¸»¿¬¸Í¬¿·²´» ¬»»´ ½±²¬®«½¬·±²Ó±«²¬·²¹ ¬¸®»¿¼ ïñî ÒÐÌЮ±¾» °±·¬·±² ½¿² ¾»¿¼«¬»¼ ·² ¬¸» º·»´¼ÍÔßÒÍÚ±® ðòîëðþ ¼·¿³»¬»® ¸»¿¬¸×²½´«¼» Ê·¬±² Ñó®·²¹Í¬¿·²´» ¬»»´ ½±²¬®«½¬·±²Ó±«²¬·²¹ ¬¸®»¿¼ ïñî ÒÐÌЮ±¾» °±·¬·±² ½¿² ¾»¿¼«¬»¼ ·² ¬¸» º·»´¼ÍÔÒÚ±® ðòïîëþô ðòïèéþ ¿²¼ðòîëðþ ¼·¿³»¬»® ¸»¿¬¸Ó±«²¬·²¹ ¬¸®»¿¼ ïñî ÒÐÌÓ±¬ ¼«®¿¾´»ÍÔÍ°®·²¹ó´±¿¼»¼ °¿½µ·²¹ ¹´¿²¼Í°®·²¹ ¬®¿ª»´æ ïñìþ ¬± íñèþîóè °±«²¼ °®·²¹ °®»«®»Í¬¿·²´» ¬»»´ ½±²¬®«½¬·±²ôÌ»º´±² »¿´¿²¬ßª¿·´¿¾´» ©·¬¸ Þ ½¿° º±®¼·®»½¬ ³±«²¬ÍÔïîÚ±® ðòïîëþ ¼·¿³»¬»® ¸»¿¬¸Ó±«²¬·²¹ ¬¸®»¿¼ ïñè ÒÐÌÍÔïèÚ±® ðòïèéþ ¼·¿³»¬»® ¸»¿¬¸Ó±«²¬·²¹ ¬¸®»¿¼ ïñì ÒÐÌÍÔîëÚ±® ðòîëðþ ¼·¿³»¬»® ¸»¿¬¸Ó±«²¬·²¹ ¬¸®»¿¼ ïñî ÒÐÌÑ°¬·±²¿´ ïñì ÒÐÌ ³±«²¬·²¹ ¬¸®»¿¼· ¿ª¿·´¿¾´»ò ݱ²«´¬ º¿½¬±®§òïí

SPECIFY SENSOR LEAD CONFIGURATIONCATALOG TYPE 2CATALOG TYPE 3CATALOG TYPE 4CATALOG TYPE 5REDWHITE2-WIRESINGLEREDREDWHITE3-WIRESINGLEREDREDWHITEWHITE4-WIRESINGLEPotentiometricBLUEBLUEREDWHITE4-WIRESINGLECompensatingCATALOG TYPE 6CATALOG TYPE 7CATALOG TYPE 8REDREDWHITEWHITE2-WIREDUALREDREDREDREDWHITEWHITE3-WIREDUALREDREDREDREDWHITEWHITEWHITEWHITE4-WIREDUAL<strong>23</strong>00 Walden Avenue • Buffalo, New York 14<strong>22</strong>5FAX: 716-684-7433 • Phone: 716-684-4500 • 1-800-<strong>22</strong>3-<strong>23</strong>89www.conaxbuffalo.come-mail: conaxbuf@conaxbuffalo.comEuropean OfficePO Box 91 • BOGNOR REGIS PO<strong>22</strong> 7JB, EnglandFAX: +44 (0)1243 587799 • Phone: +44 (0)1243 587878e-mail: cbteurope@compuserve.com

CONAX TECHNOLOGIES<strong>23</strong>00 WALDEN AVENUE, BUFFALO, NY 14<strong>22</strong>5No. TSD 43.<strong>01</strong>8Rev. DateC 6/10/08INSTALLATION AND MAINTENANCE MANUALFORCONAXTEMPERATURE TRANSMITTERSMODEL DRTx-RTDPREPARED BY P. R. Calabrese, Prin. Elec. Design Engineer DATE 8/13/97APPROVED BY R. A. Lyon, Product Marketing Engineer DATE 8/14/97DATEDATE

No. TSD 43.<strong>01</strong>8REVISION RECORDRevisionAffectedParagraphsBrief Description of RevisionDateApprovalSignatureOrig.AllOriginal Release per E.O. QP-14988/13/97P. CalabreseAAppendix ARevised per E.O. QP-25173/<strong>23</strong>/00P. CalabreseB5.0 & Appendix ARevised per E.O. QP-34317/18/<strong>01</strong>R. CrawfordCAllRevised per E.O. QP-86076/10/08G. Barnhard

CONAX TECHNOLOGIES TSD 43.<strong>01</strong>8Rev.CPage 1 of 6INSTALLATION AND MAINTENANCE MANUALFORCONAXTEMPERATURE TRANSMITTERMODEL DRTx-RTD