BETABITE HYDRAULICS - Duncan Rogers

BETABITE HYDRAULICS - Duncan Rogers

BETABITE HYDRAULICS - Duncan Rogers

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

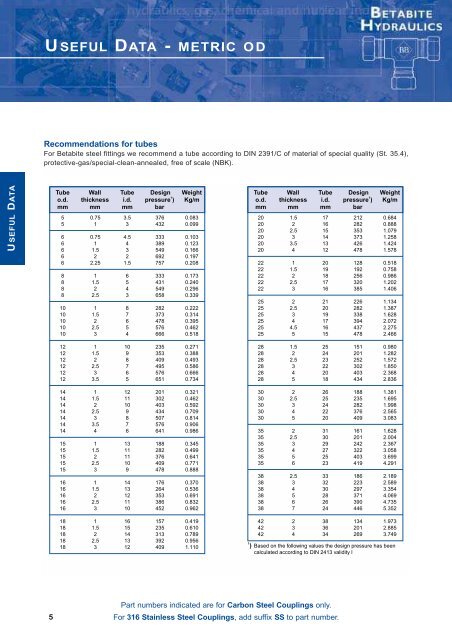

USEFUL DATA - METRIC ODRecommendations for tubesFor Betabite steel fittings we recommend a tube according to DIN 2391/C of material of special quality (St. 35.4),protective-gas/special-clean-annealed, free of scale (NBK).USEFUL DATATubeo.d.mmWallthicknessmmTubei.d.mmDesignpressure 1 )barWeightKg/m5 0.75 3.5 376 0.0835 1 3 432 0.0996 0.75 4.5 333 0.1036 1 4 389 0.1236 1.5 3 549 0.1666 2 2 692 0.1976 2.25 1.5 757 0.2088 1 6 333 0.1738 1.5 5 431 0.2408 2 4 549 0.2968 2.5 3 658 0.33910 1 8 282 0.22210 1.5 7 373 0.31410 2 6 478 0.39510 2.5 5 576 0.46210 3 4 666 0.518Tubeo.d.mmWallthicknessmmTubei.d.mmDesignpressure 1 )barWeightKg/m20 1.5 17 212 0.68420 2 16 282 0.88820 2.5 15 353 1.07920 3 14 373 1.25820 3.5 13 426 1.42420 4 12 478 1.57822 1 20 128 0.51822 1.5 19 192 0.75822 2 18 256 0.98622 2.5 17 320 1.20222 3 16 385 1.40625 2 21 226 1.13425 2.5 20 282 1.38725 3 19 338 1.62825 4 17 394 2.07225 4.5 16 437 2.27525 5 15 478 2.46612 1 10 235 0.27112 1.5 9 353 0.38812 2 8 409 0.49312 2.5 7 495 0.58612 3 6 576 0.66612 3.5 5 651 0.73414 1 12 201 0.32114 1.5 11 302 0.46214 2 10 403 0.59214 2.5 9 434 0.70914 3 8 507 0.81414 3.5 7 576 0.90614 4 6 641 0.98615 1 13 188 0.34515 1.5 11 282 0.49915 2 11 376 0.64115 2.5 10 409 0.77115 3 9 478 0.88816 1 14 176 0.37016 1.5 13 264 0.53616 2 12 353 0.69116 2.5 11 386 0.83216 3 10 452 0.96218 1 16 157 0.41918 1.5 15 235 0.61018 2 14 313 0.78918 2.5 13 392 0.95618 3 12 409 1.11028 1.5 25 151 0.98028 2 24 201 1.28228 2.5 23 252 1.57228 3 22 302 1.85028 4 20 403 2.36828 5 18 434 2.83630 2 26 188 1.38130 2.5 25 235 1.69530 3 24 282 1.99830 4 22 376 2.56530 5 20 409 3.08335 2 31 161 1.62835 2.5 30 201 2.00435 3 29 242 2.36735 4 27 322 3.05835 5 25 403 3.69935 6 23 419 4.29138 2.5 33 186 2.18938 3 32 223 2.58938 4 30 297 3.35438 5 28 371 4.06938 6 26 390 4.73538 7 24 446 5.35242 2 38 134 1.97342 3 36 201 2.88542 4 34 269 3.7491) Based on the following values the design pressure has beencalculated according to DIN 2413 validity l5Part numbers indicated are for Carbon Steel Couplings only.For 316 Stainless Steel Couplings, add suffix SS to part number.