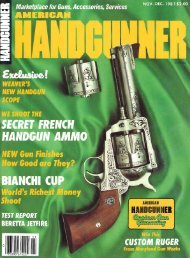

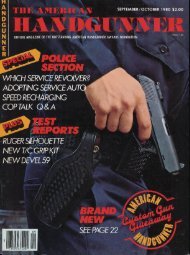

March/April 1983 - American Handgunner

March/April 1983 - American Handgunner

March/April 1983 - American Handgunner

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Here's the Walther P38 family, which led to developmentof P5: .22 P38, right; P4, center, and an early P38K, left.Both the P38IV and P38K are expectedto be discontinued; obviously, their placewill be taken by the P5, which owes its relativelylight weight to its aluminum frame.Since World War II, Walther has beenmaking its military-size automatics withhigh-strength, forged aluminum frames.These forged frames are completely machinedto extreme accuracy. It has alwaysbeen claimed that a forged machined parthas more inherent strength than a precisioncast one. If such an advantage doesexist for the machined part, it is quicklyovercome by beefing-up the cast part togive comparable strength in a criticalcross-section.The take-down for cleaning the WaltherP5 is simple. Remove the magazine and becertain there is no cartridge in the chamber.The slide and barrel are then movedback about 1,4 inch and the take-down leveris swung down. The slide and barrel cannow be disassembled, forward. The barreland its lock, which is staked in place, arenow removed from the slide. This completesthe tool-less disassembly of the P5.When the safety drop is released, and hasreturned to its off position, the firing pin isstill down and resting in a hole in the faceofthe hammer. The only time the firing pincan be impinged by the hammer is at theend of the trigger pull, when either thehammer is at full cock or the hammer hasbeen brought to the firing position by along pull on the trigger.The slide stop, which is part ofthe safetydrop system, works as follows: when thelast round has been fired, the slide remainsopen. A loaded magazine is then insertedand the. safety drop is given a downwardpush with the thumb. The slide comes forward,chambering a round. The safety,when thumb pressure is released, raisesunder its own tension. If a second thumbpressure is applied, the hammer dropssafely to its down position.The P5 should be carried hammer downand safety off; it is perfectly safe in thisposition, since there is no possible contactbetween the hammer and the firing pin.This probably represents the acme insafety systems and was introduced earlieron other German pistols but never, to myContinued on page 84DIFFERENT SAFETIESThe P5 appears to have the same safetyas the one introduced in the P38IV and theP38K. Not so. The P5 safety drop lever isincorporated in the slide stop and is framemounted,not slide-mounted. Both safetieS'are spring-loaded and return to the "off"position when thumb pressure is released.There is one big internal difference betweenthe P5 and the P38IV/P38K. In theP5, the firing pin is not in the hammer'spath before it is dropped by the safety.AMERICAN HANDGUNNER • MARCHIAPRIL <strong>1983</strong>39