colorexpert - Spies Hecker

colorexpert - Spies Hecker

colorexpert - Spies Hecker

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

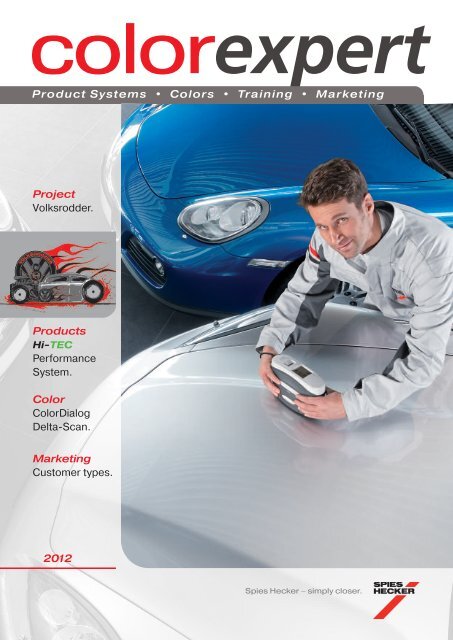

<strong>colorexpert</strong><br />

Product Systems • Colors • Training • Marketing<br />

Project<br />

Volksrodder.<br />

Products<br />

Hi-TEC<br />

Performance<br />

System.<br />

Color<br />

ColorDialog<br />

Delta-Scan.<br />

Marketing<br />

Customer types.<br />

2012<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.

2 <strong>colorexpert</strong><br />

Win a Volksrodder<br />

T-shirt at:<br />

Our trade is constantly changing. If bodyshops<br />

want not only to keep up, but<br />

also to compete on the highest level at all<br />

times, they have to be open to new technological<br />

trends. At the same time, values<br />

and traditions can still be useful. It is<br />

our conviction that a proven business<br />

strategy is the best foundation for innovation<br />

– and ultimately for success. We,<br />

to, can look back on a long and successful<br />

tradition – this year <strong>Spies</strong> <strong>Hecker</strong> celebrates<br />

its 130th anniversary.<br />

In touch with the<br />

industry.<br />

One of <strong>Spies</strong> <strong>Hecker</strong>’s key principles has<br />

always been to identify trends early on<br />

and come up with matching solutions.<br />

This way, its partner businesses can respond<br />

flexibly and skilfully and master all<br />

the challenges they’re confronted with.<br />

In this issue, you can find out all about<br />

such technological milestones as the Hi-<br />

TEC Performance System. Whatever the<br />

material – base coat, clear coat or surfacer<br />

– it’s all adapted to Permahyd ® Hi-<br />

TEC 480. The outcome is even greater<br />

process security and nothing but immaculate<br />

finishes.<br />

There’s also a new product for application<br />

on large surfaces. VOC-compliant<br />

Permafleet ® Hi-TEC 680 Base Coat<br />

brings an entirely new standard of refinish<br />

quality to commercial vehicles.<br />

Editorial<br />

Thomas Melzer,<br />

Brand Manager<br />

<strong>Spies</strong> <strong>Hecker</strong> GmbH.<br />

Tradition meets innovation.<br />

www.spieshecker.com/<br />

volksrodder<br />

Dear Reader,<br />

And talking of technologies of the future:<br />

as you know, <strong>Spies</strong> <strong>Hecker</strong> has had a<br />

strong commitment to electronic colour<br />

measurement for some time now. With<br />

the new ColorDialog Delta-Scan, it is<br />

now possible to identify not only the<br />

color, but also the effect at the same<br />

time – with precision, ease and speed.<br />

Along with the above-mentioned and<br />

many other innovations, we are also bringing<br />

back history in a new guise in this<br />

issue. Do you remember the “Pretzel<br />

Beetle”? Austrian airbrush artist Knud Tiroch<br />

has breathed new life into a scrapped<br />

model. The outcome is a powerful<br />

engine, broad tyres and a low-riding<br />

body – a hot rod, painted with the Hi-TEC<br />

Performance System. The Volksrodder is<br />

a wonderful example of the accomplished<br />

blending of the time-honoured with<br />

the totally new. Allow yourself to be inspired<br />

– and take part in our prize competition<br />

at the same time.<br />

Enjoy your read of the new issue dedicated<br />

to the fascinating world of colors and<br />

painting!<br />

Yours Thomas Melzer<br />

<strong>colorexpert</strong> – tips and information for bodyshops • © SPIES HECKER GMBH, 50858 Köln, Horbeller Str. 17, Germany • Email: Patrick.Kreuz@deu.spieshecker.com Internet: www.spieshecker.com<br />

• Responsible under the German Press Act: Karsten Jürs • Editors: Patrick Kreuz, Christian Simmert • Layout: Adfactory GmbH, Düsseldorf • Text: Mediaservice GmbH, Neuss<br />

Reader: LLINGUA, Gelsenkirchen • Images: <strong>Spies</strong> <strong>Hecker</strong>, CH Coatings AG, ITW Finishing Systems and Products, Hedson Technologies AB, Metalak B.V. • Reproduction, even in part, only<br />

by permission of the editors. The data and information on the suitability and usage of our products are not binding and do not release the user from his responsibility to carry out his own<br />

tests on their suitability for the intended purposes and processes. The product names mentioned in the articles are predominantly registered trademarks.

Whether solid colors, metallics or effects,<br />

the range of OEM colors is growing in<br />

complexity. For years now, <strong>Spies</strong> <strong>Hecker</strong><br />

has been assisting innovative bodyshops<br />

with digital color management – and is<br />

constantly refining it so that bodyshops<br />

can respond effectively even to the very<br />

latest trends.<br />

“With the newly developed ColorDialog<br />

Delta-Scan, refinishers get to the matching<br />

formula faster,” says Dietmar Wegener,<br />

<strong>Spies</strong> <strong>Hecker</strong> color expert,<br />

adding: “The device measures not only<br />

the color but also the effect, which simplifies<br />

data evaluation enormously. For<br />

each reading, the device issues a correction<br />

formula that can be displayed<br />

side-by-side with the measured color on<br />

the screen. Comparisons with color<br />

chips will soon be a thing of the past.”<br />

Another new feature of the ColorDialog<br />

Delta-Scan is the color touchscreen.<br />

Wegener: “Convenient menu guidance is<br />

assured with neatly laid-out, self-explanatory<br />

icons.” For inputs, it’s also possible<br />

to use the touch pen planted on the<br />

side of the Delta-Scan housing.<br />

ColorDialog<br />

A new dimension in color<br />

measurement.<br />

The new ColorDialog Delta-Scan measures the color and the<br />

effect at the same time – quickly, precisely and digitally.<br />

Precise measurement.<br />

The Delta-Scan measures the paint surface<br />

with multi-angle optics and analyses<br />

the color effect at the same time. “A rubber<br />

ring on the measuring head excludes<br />

external light and reflections to improve<br />

the quality of the reading,” says color<br />

specialist Wegener, listing further technical<br />

innovations of the device. In addition,<br />

four contact pins on the measuring<br />

head ensure that the ColorDialog Delta-<br />

Scan sits correctly on the surface. Additional<br />

LEDs increase the light intensity<br />

during measurement and contribute to<br />

exceptionally precise scanning.<br />

The calibration of the Delta-Scan also<br />

saves time, as the much longer intervals<br />

reduce the associated workload. “Usually,<br />

the refinisher only has to calibrate<br />

the device once a month,” Wegener explains.<br />

The software does<br />

more.<br />

The CRplus software has also been upgraded.<br />

The new software module ensures<br />

the straight forward application and<br />

evaluation of the measurement results.<br />

The color comparison on the screen has<br />

a very user-friendly design and takes you<br />

quickly to the desired color formula. The<br />

measured data are automatically compared<br />

with some 250,000 formulas from<br />

the database. The Delta-Scan also has<br />

internal data storage for the direct retrieval<br />

of car manufacturer and other color<br />

information.<br />

There’s no doubt about it: whatever the<br />

paint finish – solid color, metallic or pearl<br />

effect – with the new ColorDialog Delta-<br />

Scan, forward-looking refinishers get to<br />

the desired formula faster<br />

The device is due for launch soon.<br />

3

4 <strong>colorexpert</strong><br />

Hot rod Beetle!<br />

A powerful engine and broad tyres. A<br />

chopped, low-riding body. And yet, when<br />

you see the hot rod, you can’t help thinking<br />

of a VW Beetle. It’s an art project, an<br />

impassioned statement on behalf of<br />

Volkswagen’s cult car. A modified and<br />

tuned variation on a historic car theme.<br />

“The Beetle is a car that’s accompanied<br />

people down the years, from one generation<br />

to the next,” says Austrian airbrush<br />

artist Knud Tiroch about his project. “It<br />

has inspired love, hate, desperation and<br />

hope. As a military utility vehicle in the<br />

war. And then as the first car that became<br />

affordable to many in the 1950s. It<br />

has seen revolutions and experienced<br />

Flower Power in the Sixties. It is the<br />

Volkswagen per se.”<br />

Car with a soul.<br />

The artist has been specialising in “pimping<br />

up” muscle cars and hot rods for<br />

years now. In his Hot Rod Hangar in<br />

Vienna, Knud Tiroch and his son Dominic<br />

have breathed new life into the ‘Pretzel<br />

Beetle’. “This hot rod tells a new story of<br />

the forgotten Beetle that was abandoned<br />

on the scrapheap of<br />

history, along with a<br />

battered old Opel Diplomat<br />

with a GM V8<br />

engine,” says the artist,<br />

explaining his<br />

source of inspiration.<br />

“One day, the Opel really was scrapped.<br />

And the wings were taken off the Beetle.<br />

The little one thought to himself: ‘Surely<br />

this can’t be the end of the road?!’ It<br />

wasn’t, for the Beetle came back to life<br />

as the ‘Volksrodder’.”<br />

The hot rod style<br />

The project has a message: “If you firmly<br />

believe in something, it may one day<br />

come true.” This idea is indeed motivation<br />

for many – including the <strong>Spies</strong> <strong>Hecker</strong><br />

team in Cologne. This was where<br />

the complete body was rebuilt and painted<br />

with <strong>Spies</strong> <strong>Hecker</strong> Hi-TEC 480. Many<br />

motifs and the Volksrodder’s logo have<br />

been incorporated in the paint finish itself.<br />

There’s a hint of barbed wire trailing<br />

across the vehicle superstructure. The<br />

Top-Story<br />

Beetlemania meets Hot Rod Art. Knud Tiroch and<br />

<strong>Spies</strong> <strong>Hecker</strong> present a global first: the “Volksrodder”.<br />

Dominic and Knud Tiroch

interior of the Volksrodder is more reminiscent<br />

of that of a B-52 bomber. Lots of<br />

brushed aluminium, heavy bomber seats,<br />

retro style and plenty of brass. The windows<br />

are of red solar glass to provide protection<br />

from the UV radiation on the salt<br />

lake. “Its look harks back to the highspeed<br />

races on American salt flats, the<br />

Bonneville Salt Flat Races,” says Knud Tiroch,<br />

explaining his interpretation of the<br />

interior. The position of the 700 hp engine<br />

symbolises the typical hot rod. Originally<br />

at the rear of the Beetle, it is now, in a<br />

powered-up version, at the front. Strongly<br />

accentuated with body parts made of<br />

milled aluminium.<br />

Many details on the Volksrodder only reveal<br />

themselves at second glance. The<br />

Floor panel<br />

bottom floor panel has been embellished<br />

with graffiti of the Berlin Wall. The artist<br />

explains: “With this graffiti, I want to show<br />

that history always accompanies us in our<br />

lives – like the Wall that unnecessarily divided<br />

Germany for almost 30 years. This<br />

is why I’ve added this feature to the lowest<br />

part of the body.”<br />

We know no bounds.<br />

Technically, the project was<br />

a real challenge for the<br />

<strong>Spies</strong> <strong>Hecker</strong> team. “We’ve<br />

achieved our goal,” says a<br />

proud Frank Barduna,<br />

Technical Manager at <strong>Spies</strong><br />

<strong>Hecker</strong>. “Despite the historic<br />

body of bare steel and<br />

the new add-on parts, we succeeded in<br />

applying an absolutely immaculate finish.”<br />

Knud Tiroch has been working with<br />

<strong>Spies</strong> <strong>Hecker</strong> for 30 years now. “I really<br />

appreciate these guys with their specialised<br />

paint knowledge and their commitment,”<br />

says the Austrian, happy with their<br />

latest cooperative venture. “For my projects<br />

I need the best technical solutions<br />

available on the market. For the finish, I<br />

didn’t hesitate to choose the Hi-TEC Performance<br />

System.”<br />

Passion for<br />

technology<br />

The Volksrodder is unique. Handmade<br />

down to the finest detail, no compromises.<br />

Weight 700 kilos with a 700 hp<br />

engine.<br />

Body: VW Beetle Type VW 1 (Pretzel<br />

Beetle), dating back to the beginning<br />

of the Nineteen Fifties.<br />

Engine: Chevrolet racing engine,<br />

6.6 litre displacement, 700 hp, 8 cylinders,<br />

700 R transbrake (General<br />

Motors), computer-controlled<br />

ACCEL injection system.<br />

Typical hot rod: Roof chopped by<br />

20 cm. The body has been channelled,<br />

i.e. lowered over the frame, the<br />

wheel arches enlarged and the engine<br />

exposed at the front. Working<br />

hours roughly 1,000.<br />

Tyres: 525/15 Pro-Drag.<br />

Paint: <strong>Spies</strong> <strong>Hecker</strong> Permahyd ®<br />

Hi-TEC Performance System.<br />

5

6 <strong>colorexpert</strong><br />

Interview & Practice<br />

A class apart!<br />

The paint finish on the Volksrodder called for a technical<br />

master class. Frank Barduna describes how the <strong>Spies</strong><br />

<strong>Hecker</strong> team rebuilt the body and surfaces.<br />

Michael Kramer, Jörg Sandner and Frank<br />

Barduna (from the left to right) teamed up<br />

with Knud Tiroch to style the Volksrodder at<br />

the <strong>Spies</strong> <strong>Hecker</strong> Center.<br />

What was special about<br />

this project?<br />

Substrate preparation and the painting<br />

were very precise. Don’t forget that this<br />

is, after all, a chopped Fifties Beetle body.<br />

Bare steel. The geometry of the Beetle<br />

and the production of an absolutely

super-smooth surface – this alone was a<br />

huge challenge, but one that we were determined<br />

to overcome.<br />

What substrate work<br />

was necessary?<br />

Every single part had to be treated with<br />

meticulous care. The overall surface had<br />

to be rebuilt to create a tangible level surface<br />

and smooth transitions between adjacent<br />

parts, inside and outside. We had<br />

to adjust the roof beam, door frame and<br />

gap dimensions again and again. These<br />

jobs alone kept the team busy for a whole<br />

week. It was particularly important<br />

throughout the project to make sure that<br />

the treated surface got corrosion protection<br />

again and again. This is the only<br />

way of giving the Volksrodder a lasting<br />

and high-quality finish.<br />

The design and paint<br />

finish are also a class<br />

apart.<br />

Correct. First we applied the base coat in<br />

the ground color. Then Knud Tiroch applied<br />

the design at the <strong>Spies</strong> <strong>Hecker</strong> Center.<br />

After this, we sprayed an effect color<br />

over the plastic film, then peeled off the<br />

film and applied the clear coat. After sanding,<br />

we applied clear coat again and<br />

sanded it again. Then we jointly applied<br />

the logo with the Volksrodder signet and<br />

flames on the side, sprayed another film<br />

of clear coat over it and sanded it. This<br />

cycle was repeated again before the final<br />

film of clear coat was applied. Finally, the<br />

surface was totally smooth.<br />

How much time did you<br />

invest in it?<br />

Difficult to say, because we were totally<br />

absorbed in the project together with<br />

Knud Tiroch. It must have been more than<br />

250 working hours. But that’s all water<br />

under the bridge. What counts is the result.<br />

Thanks, Frank,<br />

for telling us the story.<br />

Step by step: The hot<br />

rod paint system<br />

Step 1: Corrosion protection on<br />

the body<br />

– Priomat ® Wash Primer 4075<br />

– Permasolid ® HS Vario Surfacer<br />

5320 grey<br />

Step 2: Rebuilding the surfaces<br />

– Raderal ® IR Premium Putty 2035<br />

– Raderal ® Fine Putty 0911<br />

Step 3: Corrosion protection on<br />

sanded-through areas<br />

– Priomat ® Wash Primer 4075<br />

– Permasolid ® HS Vario Surfacer<br />

5320 grey<br />

Step 4: Smoothing the surfaces,<br />

levelling minor irregularities<br />

– Raderal ® Spray Polyester 3508<br />

Step 5: Corrosion protection on<br />

the bare metal, isolating the surfacer,<br />

final touches<br />

– Priomat ® Wash Primer 4075<br />

– Permasolid ® HS Performance<br />

Surfacer 5320* grey<br />

Step 6: Painting<br />

– Permahyd ® Hi-TEC 480<br />

– Permasolid ® HS Clear Coat 8055<br />

*Permasolid ® HS Performance Surfacer 5320<br />

grey is due for launch soon.<br />

7

8 <strong>colorexpert</strong><br />

Cross-border network.<br />

“Train the Trainer” is the name of the international<br />

<strong>Spies</strong> <strong>Hecker</strong> training strategy.<br />

At regular intervals, Frank Barduna<br />

of Technical Service International trains<br />

technical consultants from roughly 18<br />

countries at Cologne headquarters. The<br />

expert also travels repeatedly to the various<br />

<strong>Spies</strong> <strong>Hecker</strong> locations so that he<br />

can work with local technicians under<br />

local conditions.<br />

In this interview, Samuel Martínez from<br />

Spain, Mariusz Safarzyński from Poland<br />

and Frank Barduna report on their close<br />

communication – and outline how all<br />

<strong>Spies</strong> <strong>Hecker</strong> refinishers all over the<br />

world ultimately benefit.<br />

What’s the thinking behind<br />

the “Train the Trainer”<br />

strategy?<br />

Barduna:The most important thing for us<br />

at <strong>Spies</strong> <strong>Hecker</strong> is the close personal<br />

networking between all of our people, irrespective<br />

of national borders. Whether<br />

the subject is innovative paint technologies<br />

or complex repair methods, only<br />

those who are right up to date can explain<br />

properly to customers what it’s all<br />

about. And this doesn’t just mean making<br />

our knowledge at German headquarters<br />

available all over the world. We<br />

can of course resort to the latest equipment<br />

and hypermodern technology. But<br />

for us it’s just as important to listen to the<br />

experience of technicians in other countries.<br />

We’re fully committed to the principle<br />

of mutual learning.<br />

The second part of the strategy envisages<br />

training sessions locally – so as to<br />

lend depth to the newly acquired<br />

knowledge. We witness how the technical<br />

consultants pass on their expertise to<br />

their technicians – who pass it on in turn<br />

to bodyshops. We therefore attach great<br />

importance to a uniformly high quality of<br />

training. It’s the bodyshop that ultimately<br />

benefits, in whatever country it happens<br />

to be. This is the only way we can uphold<br />

the high standard of our wide-ranging<br />

technical support services.<br />

Incidentally, we’re constantly extending<br />

the strategy and adapting it to current<br />

developments and trends. For instance,<br />

we’ve currently got an e-learning project<br />

in preparation which will enable technicians<br />

in the various countries to obtain additional<br />

training online.<br />

What do you as technical<br />

consultants appreciate<br />

about the training<br />

sessions at the <strong>Spies</strong><br />

<strong>Hecker</strong> Center?<br />

Safarzyński: Matt<br />

paints, new effect finishes,<br />

modern application<br />

techniques and<br />

color identification: a<br />

great many technical<br />

innovations come onto<br />

the market every year. And this means new<br />

challenges for us refinishers. At headquarters<br />

in Cologne, we’ve got the chance to<br />

find out about and discuss new trends. It’s<br />

an ideal forum for exchanging views. To be<br />

quite honest, we’re right at the source …<br />

Training/Interview<br />

Martinez: I agree entirely.<br />

In Cologne I get<br />

straight answers to<br />

the questions that are<br />

important for my work<br />

in Spain. There’s also<br />

a spirit of familiarity at<br />

headquarters. The atmosphere and the<br />

people are incredibly welcoming, helpful<br />

and obliging – and this for me is the best<br />

basis for successful cooperation.<br />

Frank, you train the experts<br />

in their countries.<br />

Barduna: Yes, as I<br />

mentioned just now,<br />

this is extremely important<br />

for us. Because<br />

only on location in the<br />

various countries can<br />

we personally experience<br />

the different conditions under which<br />

our customers have to work. The equipment,<br />

environmental factors and the local<br />

mentality – only when we go personally to<br />

the places where our consultants train our<br />

customers can we gain a genuine understanding<br />

of the realities in the country in<br />

question. This is an absolutely essential<br />

aspect of our strategy. We want to be simply<br />

closer.<br />

Mariusz and Samuel,<br />

what’s your assessment<br />

of local training?<br />

Safarzyński: It’s definitely a very useful<br />

addition to training in Cologne. The

people in Cologne give us wholehearted<br />

support with implementation – such as in<br />

the changeover to the Permahyd ® Hi-TEC<br />

480 waterborne base coat system.<br />

Martínez: There’s no substitute for the<br />

training sessions locally in Madrid. In<br />

Spain we’ve got a market situation that<br />

differs a lot from that in other countries.<br />

And, taking the example of climate, we’ve<br />

got to battle with totally different conditions<br />

than the Fins, for example. And then<br />

we not only use to some extent different<br />

equipment, but it’s also important to realise<br />

that Spanish customers have their<br />

own views and needs.<br />

What are the important<br />

factors in other countries?<br />

Barduna: I’d like to take up the example<br />

of the climate. Due to the hot, dry weath-<br />

er in summer in countries like Spain, refinishers<br />

are confronted with tough conditions.<br />

Up to 40 °C in the sun and hardly<br />

any humidity – yet the ideal storage and<br />

application temperature for paint materials<br />

is 20 °C. Appropriate measures therefore<br />

have to be taken in the bodyshop to<br />

safeguard the quality of the paints and<br />

systems. In a country like Poland, on the<br />

other hand – and Mariusz knows all about<br />

it – the winters are extremely cold. Here<br />

again, all conceivable precautions have<br />

to be taken to prevent paint defects. We<br />

give advice on how to correctly store,<br />

transport and apply the material.<br />

Or let’s take another example. Owing to<br />

the financial crisis, there’s been a strong<br />

emphasis on efficiency for some time in<br />

almost all countries. Many bodyshops<br />

therefore come to the Training Center to<br />

gird themselves for the increasingly fierce<br />

competition in their countries.<br />

And we’re ready to help them.<br />

Frank, Mariusz and Samuel –<br />

thanks very much for the<br />

interview!<br />

A turn<br />

for the<br />

better.<br />

The <strong>Spies</strong> <strong>Hecker</strong><br />

Mixing Ratio Disc.<br />

This is an indispensable aid that the<br />

refinisher should always have within<br />

reach. On the two-sided disc are all<br />

the VOC-compliant paint products<br />

including Permahyd ® Hi-TEC 480<br />

that are of relevance for modern bodyshops.<br />

The disc indicates the mixing<br />

ratios of primers, surfacers,<br />

base coat and clear coat and the<br />

matching additives and hardeners.<br />

As of now, the handy Mixing Ratio<br />

Disc from <strong>Spies</strong> <strong>Hecker</strong> is also available<br />

in digital form for mobile use on<br />

smartphones and iPads.<br />

9

10 <strong>colorexpert</strong><br />

Tone colors. which now handles sales of WERSI or-<br />

<strong>Spies</strong> <strong>Hecker</strong> brings color to the world of<br />

music. Be it Sunset Stream, Luminous<br />

Blue Pearl or Macadamia Brown Metallic,<br />

modern Permahyd ® Hi-TEC colors are as<br />

of now revitalising the image of WERSI<br />

organs. The most celebrated example is<br />

the show organ of internationally famed<br />

composer, music producer and virtuoso<br />

organist Robert Bartha. His LOUVRE<br />

GS100 has been painted in Volcano<br />

Magic, a color specially developed for<br />

WERSI. “We’re delighted to be able to<br />

work with the MUSIC STORE in Cologne,<br />

White on the ascendancy.<br />

Worldwide, 60 to 70 per cent of cars have<br />

white, silver, black or grey paintwork. In<br />

2011 however, white surged to the fore.<br />

According to the Global Automotive<br />

Color Popularity Report, this color occupies<br />

the No. 1 position worldwide. This<br />

represents a quantum leap, as white was<br />

back in fourth place in 2010. Among car<br />

colors in Europe, black still heads the<br />

field, but now has white hard on its heels.<br />

But white is not just white. As an additional<br />

base coat film, pearl is a source of<br />

new effects, such as Volkswagen’s Oryx<br />

White. “There’s a clear trend towards<br />

gans. As a result, we’ve been privileged<br />

to support the world’s greatest artist in<br />

the organ scene with paint products for<br />

his show instrument,” says chuffed color<br />

expert Dietmar Wegener. “Even today,<br />

organ music has plenty of fans, young<br />

and old. The ‘dusty’ image of what was<br />

once known as the ‘home organ’ is well<br />

and truly a thing of the past,” he reports.<br />

A claim underscored by the new paint finishes<br />

now available for WERSI organs.<br />

light-colored pearl effects,” Frank Barduna<br />

of Technical Service International<br />

explains. “On the production line, these<br />

are now being applied more often than<br />

ever in multi-stage finishes, simply because<br />

much more has now become technically<br />

possible.”<br />

“However, repairs to many new colors are<br />

only possible with the special effect pigments<br />

that are additionally available<br />

today.”<br />

Hi-TEC Tools<br />

The right additive<br />

every time!<br />

The <strong>Spies</strong> <strong>Hecker</strong> Climate<br />

Poster for Permahyd ®<br />

Hi-TEC 480 provides at-aglance<br />

assistance.<br />

Which additive should the refinisher use<br />

when applying Permahyd ® Hi-TEC 480?<br />

WT Additive 6050 or WT Additive 6052?<br />

The <strong>Spies</strong> <strong>Hecker</strong> Climate Poster tells the<br />

refinisher which of the two additives is<br />

used with Hi-TEC 480 Base Coat for the<br />

given ambient temperature, humidity and<br />

size of repair – quickly and at a glance.<br />

Automotive color preferences in<br />

2011. Europe’s favorite colors.

Equipment<br />

A spirit of<br />

tradition<br />

and passion.<br />

“Dr Allen DeVilbiss” – a man who wrote paint history.<br />

Effortlessly wielding modern spray guns,<br />

today’s refinishers skilfully apply paint to<br />

vehicle surfaces. This item of equipment,<br />

the stock-in-trade of the present-day<br />

bodyshop, can in fact look back on a<br />

long development history.<br />

We’ve all heard of Carl Benz. For it was<br />

this German that invented the motor car<br />

in Stuttgart 125 years ago. But what few<br />

people know is that the invention of the<br />

spray gun is at least as old as the first automobile.<br />

When Henry Ford had his first<br />

car series built on the production line in<br />

1912, “Permanent” vehicle paint was already<br />

being produced by <strong>Spies</strong> <strong>Hecker</strong><br />

in Cologne. At the time, asphalt and oil<br />

paints were still applied with a brush – a<br />

method that was hardly compatible with<br />

the production line. This is when the<br />

spray gun really came into its own.<br />

From the atomiser to<br />

the modern spray gun.<br />

Its history goes back to the 1880s. At the<br />

time, it was usual for doctors to coat patients’<br />

sore throats with Vaseline or<br />

goose grease – a cumbersome but nevertheless<br />

highly efficacious remedy. Yet<br />

the doctor and tinkerer Dr Allen DeVilbiss<br />

in rural Ohio, USA, was convinced there<br />

must be a more pleasant way of administering<br />

treatment to his patients with sore<br />

throats.<br />

In his quest for an effective method of<br />

treatment, he developed in his little<br />

workshop the first adjustable spraying<br />

device consisting of a rubber ball, a<br />

metal can and a short tube. The doctor<br />

filled the metal container with Vaseline<br />

and heated it over the flame of a candle<br />

to melt it into a sprayable liquid. When<br />

the ball was squeezed, the device released<br />

a cloud of medicine. He then fitted<br />

an adjustable tip enabling him to vary<br />

the spray pattern. DeVilbiss lost no time<br />

in applying for a patent.<br />

This was effectively the birth of the modern<br />

spray gun. Not only did the invention<br />

bring welcome relief to his patients,<br />

but word of it also soon got around – and<br />

the atomiser went into mass production.<br />

In 1907, finally, his son Tom DeVilbiss<br />

manufactured the first industrial version<br />

of the medical device – at just the right<br />

time. Because in car production, Henry<br />

Ford was not alone in his search for more<br />

effective paint application methods.<br />

Even today, the name of DeVilbiss stands<br />

alongside Adolf-Friedrich <strong>Hecker</strong> at the<br />

dawn of modern paint history – a history<br />

undoubtedly accelerated by car manufacture<br />

and such pioneers as Henry Ford<br />

and Carl Benz. In a spirit of tradition, passion<br />

and innovative enterprise, the modern<br />

spray gun has advanced to what it<br />

is today from its beginnings over 125<br />

years ago.<br />

11

12 <strong>colorexpert</strong><br />

Bodyshops rank among the businesses<br />

with high energy consumption. What really<br />

push costs up are ventilating and<br />

heating the booths and drying. Starting<br />

up the dryer in order to temper individual<br />

body parts is particularly costly. Experts<br />

estimate as much as eight euros per<br />

hour of operation. With steadily rising<br />

energy costs, it’s worth taking a closer<br />

look at the drying process.<br />

“By organising processes effectively and<br />

using IR dryers, refinishers can cut their<br />

energy costs,” says <strong>Spies</strong> <strong>Hecker</strong> specialist<br />

Wolfgang Feyrer. “Compared to<br />

the convective drying of individual body<br />

parts, energy consumption can be reduced<br />

by almost 70 per cent. So this is an<br />

area where the bodyshop can really economise.”<br />

Energy<br />

Red hot technology.<br />

Modern infrared dryers cut costs and optimise<br />

the drying process at the same time.<br />

Current technical<br />

trends.<br />

To keep pace with spiralling energy<br />

costs, manufacturers are constantly improving<br />

the efficiency of their IR dryers.<br />

And Hedson, the Swedish manufacturer,<br />

is no exception with its IRT brand: “With<br />

the new IRT Hyperion series, we’ve<br />

boosted energy efficiency by employing<br />

gold-coated FreeForm reflectors,” explains<br />

Kenneth Lundin, Product Manager<br />

Hedson Technologies IRT Systems. As a<br />

result, “the optimised heat distribution<br />

ensures a uniform temperature and enables<br />

a 20 per cent larger repair surface<br />

to be treated in the same drying time.”<br />

The object is directly heated without the<br />

ambient air being warmed at the same<br />

time.<br />

However, it’s not a question of the technology<br />

alone. You have to use the IR drying<br />

technology intelligently if you want to<br />

save energy. “Parameters such as object<br />

distance, temperature, drying time<br />

and temperature increase have to be<br />

precisely set,” says IRT expert Kenneth<br />

Lundin, enumerating the key factors.<br />

“Modern IR dryers are capable of storing<br />

these data. This gives the refinisher<br />

greater process security and creates<br />

ideal conditions for optimum results.”<br />

Many IR dryers are flexible in their use.<br />

Along with the drying of putty and surfacer,<br />

they can also be used for base and<br />

clear coat – both for part resprays and<br />

for spot repair jobs. Manufacturers offer<br />

different types of equipment. IRT dryers,<br />

for example, can be used as cassette<br />

dryers on a mobile stand or as railmounted<br />

systems in the spray booth.<br />

With a hand-held lamp, the unit is also<br />

capable of drying poorly accessible<br />

parts of the vehicle.<br />

IR drying times<br />

Material Minutes<br />

Putty 2 – 3<br />

Surfacer 3 – 7<br />

Primer 5 – 8<br />

Waterborne base coat 2 – 4<br />

Top coat 6 – 10<br />

Clear coat 5 – 10<br />

Surfacer on plastic 7 – 10<br />

Top coat on plastic 15 – 18<br />

Clear coat on plastic 15 – 18<br />

The listed times refer to the IRT Hyperion<br />

PcAuto series. Source: IRT.

Accessories<br />

Taking a new tack.<br />

From pre-treatment right through to final polishing,<br />

using the right cloths gives you the assurance of an<br />

immaculate paint finish.<br />

Sontara ® Degreasing Cloth<br />

Dirt and dust are frequent causes of<br />

paint defects – and that’s why absolute<br />

cleanliness is essential in the bodyshop.<br />

“Even if the pressure of deadlines and<br />

costs often dominates the refinish process,<br />

consistent cleaning always pays<br />

off,” stresses Iiro Hakola of DuPont Sontara<br />

® . But what are the important points<br />

to bear in mind when cleaning?<br />

“You can only create dust- and greasefree<br />

surfaces if you use technically highgrade<br />

cloths with special properties<br />

together with the matching cleaners and<br />

silicone removers,” the expert explains.<br />

In bodyshops you can often find cloths<br />

coated with adhesive. This is where caution<br />

is advised, for cloths containing<br />

chemicals leave a film on the surface<br />

being coated. “The product should<br />

therefore contain as little tack material as<br />

possible so as to prevent wetting problems.”<br />

Quick and reliable<br />

absorption.<br />

For surface preparation Iiro Hakola recommends<br />

the Sontara ® Degreasing<br />

Cloth that the refinisher uses for thorough<br />

pre-treatment of the repair zone.<br />

The cloth has a textured surface on one<br />

side and can be relied on to quickly wipe<br />

up silicone remover, for instance. “Particularly<br />

when used with water-based silicone<br />

removers, the cloth goes a long<br />

way towards reducing flaws in the priming<br />

materials or top coat.” The key properties<br />

of the lint-free degreasing cloth<br />

are its toughness and extreme tear resistance<br />

– even in its wet state.<br />

Before the application of surfacer, base<br />

coat and clear coat, the surface should<br />

again be thoroughly cleaned. The Son-<br />

Sontara ® Tack Cloth<br />

tara ® Tack Cloth, for instance, removes<br />

dirt and dust particles. Such a cloth<br />

should fluff as little as possible and not<br />

leave any residues,” says Hakola summing<br />

up.<br />

Cleanliness pays off!<br />

To create an immaculate surface finish,<br />

an extremely soft cloth is used – the Sontara<br />

® Polishing Cloth. “This cloth is free<br />

of additives that can cause streaks as<br />

well as being fleecy and lint-free, and its<br />

fibres are so soft that damage to the<br />

paint finish is excluded,” is the professional’s<br />

advice. This makes it ideal for polishing<br />

chrome and glass and parts of the<br />

interior.<br />

Furthermore, the various cloths should<br />

always be regularly replaced. The rule of<br />

thumb is one cloth per process. “Anyone<br />

using the same cloth the whole day<br />

shouldn’t be surprised if the paint surface<br />

turns out to be flawed.” Cleanliness<br />

simply pays off. “Using the right cloth<br />

makes far more sense than having to remedy<br />

the consequences of sloppy preparation,”<br />

says Iiro Hakola in conclusion.<br />

13

14 <strong>colorexpert</strong><br />

OEM Trends<br />

The changing face of painting.<br />

Automotive finishing is constantly changing.<br />

So what are the current and future trends?<br />

And what will be their effect on refinishing?<br />

Advances in automotive series finishing<br />

are having an ever greater effect on<br />

refinishing. More and more is now<br />

becoming technically possible on car<br />

manufacturers production lines. “Obviously,<br />

changes in OEM paintwork won’t<br />

affect refinishing overnight,” says Peter<br />

Minko, Manager Process & Application<br />

at DuPont. “At the same time, the trends<br />

emerging in the car industry are pretty<br />

momentous!”<br />

Mass-produced<br />

change.<br />

A glance at the production methods<br />

shows what’s in store for bodyshops. “In<br />

the future, the depth of roughness at the<br />

electrophoretic priming stage will be significantly<br />

reduced, which means that the<br />

substrate for subsequent base and clear<br />

coat application will be more level. The entire<br />

paint system thus becomes appreciably<br />

smoother,” is the expert’s<br />

assessment. Minko also expects the layer<br />

of surfacer to vanish in the next ten years.<br />

DuPont refers to this as its “EcoConcept”<br />

– some three million cars have so far been<br />

painted surfacer-free. Consequently, “the<br />

film thickness has to be applied extremely<br />

evenly – from one end of the car to the<br />

other,” the expert explains. “The paint film<br />

is thus more uniform. This ensures greater<br />

color constancy and better color flow.” In<br />

terms of refinishing, “the process makes<br />

color identification easier, as there are<br />

fewer different color nuances on a single<br />

vehicle.”<br />

How does a car<br />

manufacturer like<br />

Volkswagen see color<br />

trends?<br />

One thing is certain: not only are car manufacturers<br />

turning to the latest technical<br />

trends, but designers are also<br />

becoming more creative in color development.<br />

Car colors are becoming increasingly<br />

important as a selling point.<br />

“We develop the matching color<br />

language for each vehicle type and size,”<br />

says Oona Scheepers, Senior Designer<br />

Color & Trim at Volkswagen, outlining the<br />

approach at Europe’s biggest car maker.<br />

“At the IAA, for example, we presented<br />

the R-Line in Fire Spark Red Chroma.<br />

The striking four-stage effect color underlines<br />

the sporting character of the<br />

special models. Customers up to the age<br />

of 40 are often bolder in their choice of<br />

color. Motorists of 45 and upwards tend<br />

to go for what they’re familiar with and<br />

what they think will last.”eher das Beständige<br />

und Bekannte.“<br />

More coats and tinted<br />

clear coat.<br />

All vehicle manufacturers are resorting to<br />

novel effect paints with strong colors for<br />

their mass models. Nissan, for instance,

is catching the eye with its extraordinary<br />

KAB Ultimate Metal Silver, and Ford with<br />

its potent Hot Magenta and its new Midnight<br />

Sky. On the other hand, Toyota,<br />

Porsche, Opel, Renault and other manufacturers<br />

are amplifying brand identity<br />

with effect paints containing special Colorstream<br />

pigments. For bright colors,<br />

new effects are achieved with tinted<br />

clear coat. In the small car segment in<br />

particular, the clear coat gives red, for<br />

example, deeper brilliance and enhanced<br />

luminosity. On the production line<br />

today, we’re now finding more multistage<br />

finishes than ever – lighter pearl<br />

effects, for instance. “More is simply<br />

technically feasible today,” Minko concludes.<br />

This means that refinishers will<br />

be repairing three- and multi-stage colors<br />

more often from now on. “However,<br />

the refinishing of many new colors is only<br />

possible with special effect pigments.”<br />

Two current examples of refinishing:<br />

Ford’s Midnight Sky can be repaired with<br />

Permahyd ® Hi-TEC Mixing Color WT312<br />

Magic Fire. For the Chevrolet color Dynamic<br />

Orange, Hi-TEC Mixing Color<br />

WT383 Brilliant Orange is used.<br />

Finding the right color<br />

faster.<br />

“We’ve responded effectively to new<br />

trends with beautifully balanced refinish<br />

solutions and professional color management,”<br />

says Frank Barduna, Tech-<br />

nical Service International at <strong>Spies</strong><br />

<strong>Hecker</strong>, commenting finally on the refinishing<br />

trends of the future. What’s<br />

more, the mixing formulas of current colors<br />

can be retrieved straight from the Internet.<br />

One example is Midnight Sky,<br />

which Ford’s series models have only<br />

been sprayed with since 2011. Almost simultaneously<br />

with launch at Ford, the repair<br />

formulas became available in the<br />

<strong>Spies</strong> <strong>Hecker</strong> Color Finder as well. Incidentally,<br />

in addition to color codes and<br />

names, you can also find the models<br />

sprayed with Midnight Sky on the production<br />

line. Plus the colors are visually<br />

displayed.<br />

Summary:<br />

In vehicle refinishing today and in the future,<br />

not only is specialised technical<br />

knowledge called for, but also the right<br />

information on the color variant in question.<br />

Mixing formulas, special paint and<br />

its application – anyone who wants to<br />

paint cars in future, will have to be aware<br />

of the latest developments in technology<br />

and colors. Changes in series finishing<br />

will thus make the refinishing process<br />

even more challenging.<br />

How to find the right color faster:<br />

www.spieshecker.com/colorfinder<br />

15

16 <strong>colorexpert</strong><br />

Hi-TEC Performance System.<br />

Professionals use integrated paint systems. A system, for example,<br />

in which the surfacer and clear coat are precisely adapted to modern<br />

Permahyd ® Hi-TEC 480 waterborne base coat.<br />

It’s essential to have paint products you<br />

can rely on. Products that ensure easy<br />

and reliable application and powerfully<br />

enhance efficient work processes. “With<br />

the new Performance System comprising<br />

HS surfacer, Hi-TEC base coat and<br />

HS clear coat, the refinisher has a fully<br />

balanced complete package to work<br />

with,” enthuses Frank Barduna, head of<br />

Technical Service International at <strong>Spies</strong><br />

<strong>Hecker</strong>. “Paint defects are thus reduced<br />

to a minimum.”<br />

Everything in a<br />

single system.<br />

“A firm foundation is provided<br />

by new Permasolid ® HS Performance<br />

Surfacer 5320,”<br />

Frank Barduna explains. “The<br />

product is very easy to apply,<br />

shows good overspray absorption and<br />

thus dries to a smooth surface with good<br />

vertical stability and outstanding sanding<br />

characteristics.”<br />

<strong>Spies</strong> <strong>Hecker</strong> Hi-TEC 480 waterborne<br />

base coat, on the other hand, is distinguished<br />

among other things by its high<br />

opacity and color accuracy.<br />

The Performance System includes three<br />

clear coats. For universal applications,<br />

there’s Permasolid ® HS Clear Coat 8055.<br />

“It’s suitable for all repairs and is simple,<br />

flexible and reliable in its application,”<br />

the <strong>Spies</strong> <strong>Hecker</strong> expert continues. Its<br />

range of uses covers standard repairs<br />

such as mudguards and doors and<br />

partial resprays that can be handled in a<br />

single pass (1.5 coats).<br />

Permasolid ® HS Optimum Plus Clear<br />

Coat 8650 is a high-productivity clear<br />

coat that always achieves impeccable<br />

results, even in less than perfect booth<br />

conditions. Since it is also extremely flexible<br />

in its application and dries very<br />

quickly, it is ideal for use on Speed Repair<br />

jobs, for instance.<br />

For superlative results combined with reliable<br />

application, Permasolid ® HS Clear<br />

Coat 8034 is the No. 1 choice. “It too can<br />

be used on any repair and is an assu-<br />

HS Clear Coat 8055<br />

HS Optimum Plus<br />

Clear Coat 8650<br />

HS Clear Coat 8034<br />

rance of top quality,” says a delighted<br />

Frank Barduna. “It is simply ideal for design<br />

finishes and personalised full resprays<br />

and can be effortlessly applied in<br />

two coats.” Standard repairs can be executed<br />

cost-effectively in a single pass<br />

(1.5 coats). The product’s properties:<br />

good vertical stability, extra-high build<br />

and excellent gloss. The clear coat also<br />

polishes very well.<br />

All in all, the new Performance System<br />

delivers much more than just outstan-<br />

Hi-TEC<br />

ding results – and regardless of which<br />

employee applies the system. Straightforward<br />

sanding and rapid application<br />

and drying of the materials speed up vehicle<br />

processing and increase bodyshop<br />

throughput.

A system<br />

you can<br />

count on.<br />

New Permasolid ® HS<br />

Performance Surfacer<br />

5320 creates a sound<br />

substrate for all kinds of<br />

repairs.<br />

The distinctive feature<br />

of this innovative<br />

product is its<br />

high solids content.<br />

“This means a little goes a long way,”<br />

stresses Frank Barduna of Technical<br />

Service. But this is by no means all.<br />

The economical surfacer also ensures<br />

excellent overspray absorption<br />

and good surface levelling. “What’s<br />

more, the surfacer can also be quickly<br />

and easily sanded after drying.” It is<br />

applied in anything from one to three<br />

coats, and its mixing ratio with Permasolid<br />

® VHS Hardeners is 5:1.<br />

In developing this high-grade Performance<br />

Surfacer, <strong>Spies</strong> <strong>Hecker</strong> has<br />

also followed the latest trend in automotive<br />

colors. The product is therefore<br />

available not only in black and<br />

medium grey, but also of course in<br />

white. Barduna: “With these three colors,<br />

the surfacer can be adapted<br />

perfectly to the base coat.”<br />

Numerous approvals.<br />

The 2K HS sanding surfacer has meanwhile<br />

been approved by various<br />

car brands. This is becoming increasingly<br />

important, as car makers specify<br />

certain paint materials and<br />

systems for refinishes. “Because<br />

they’re bound by their guarantees<br />

and warranties,” the <strong>Spies</strong> <strong>Hecker</strong><br />

expert explains.<br />

* Permasolid ® HS Performance Surfacer 5320<br />

grey is due for launch soon.<br />

Image<br />

Sporting passions.<br />

With everything from the white Ferrari<br />

F430 and the tuned Mercedes SLS Brabus<br />

to the noble Wiesmann, the current<br />

<strong>Spies</strong> <strong>Hecker</strong> “Passions” Calendar demonstrates<br />

an enthusiasm for sport and<br />

luxury. “This time we’ve put the spotlight<br />

on sporty vehicles,” explains Peter Wingen<br />

of Marketing International. At the<br />

photo shoots, bodyshops in Belgium,<br />

Czech Republic, Germany, Italy, Spain<br />

and Switzerland pulled out all the stops<br />

with their outstanding paint finishes.<br />

The photo shoots left lasting impressions<br />

on both the bodyshops and the <strong>Spies</strong> <strong>Hecker</strong><br />

team. Peter Wingen: “The Wiesmann<br />

plant in Germany is both unique and remarkable.<br />

The picture for the calendar<br />

sheet was taken in the production shop.<br />

Despite the shop’s size and ongoing production,<br />

the sense of organisation during<br />

the shoot was fascinating.”<br />

Whatever the vehicle – an elegant classic<br />

car, spectacular model aeroplane or a<br />

huge commercial vehicle – every single<br />

subject of the new <strong>Spies</strong> <strong>Hecker</strong> Calendar<br />

2012 is a real stunner in its workshop<br />

setting. The images are supplemented by<br />

pictures of the respective owners, bodyshop<br />

managers or refinishers – all of them<br />

<strong>Spies</strong> <strong>Hecker</strong> customers with a whole-hearted<br />

dedication to painting.<br />

You can download<br />

the calendar images at<br />

www.spieshecker.com/calendar2012<br />

17

18 <strong>colorexpert</strong><br />

The new Hi-TEC 680* waterborne paint system for<br />

commercial vehicle finishes yields greater process<br />

security on large surfaces.<br />

<strong>Spies</strong> <strong>Hecker</strong>’s Permafleet ® Hi-TEC 680 is<br />

a base coat developed especially for large<br />

surfaces – on such objects as buses,<br />

drivers’ cabs, dropsides, box bodies, superstructures<br />

and special-purpose vehicles.<br />

“Our aim is for high repair quality –<br />

particularly if powerful effects are to be<br />

achieved,” says Arno Steyns, commercial<br />

vehicle specialist at <strong>Spies</strong> <strong>Hecker</strong>.<br />

Used for the original finish or for repairs,<br />

Permafleet ® Hi-TEC<br />

680 is an assurance of<br />

absolutely dependable<br />

results.<br />

The VOC-compliant<br />

Hi-TEC base coat covers<br />

a broad spectrum<br />

of colors and<br />

permits the reliable<br />

application of metallic<br />

and pearl effect colors. Thanks to its excellent<br />

overspray absorption, it proves to<br />

be economical on large surfaces as well.<br />

Arno Steyns sheds light on the technology<br />

behind it: “Permafleet ® Hi-TEC 680 Base<br />

Coat exploits patented<br />

hybrid technology and<br />

thus ensures particularly<br />

uniform effect<br />

formation. High pigmentation<br />

improves<br />

its opacity.” A specially<br />

developed additive<br />

helps to improve spraying behaviour. The<br />

expert continues: “The positive effect of<br />

Permafleet ® WT Additive 6060 on the base<br />

coat’s viscosity is an advantage when<br />

spraying large surfaces.”<br />

The top coat is impressive with its easy and<br />

flexible application and good hiding power.<br />

What’s more, it’s now also possible to<br />

mask the paint even faster and more neatly<br />

– an important factor in view of the popularity<br />

of design finishes on commercial vehicles.<br />

Commercial Vehicles<br />

New paint system for large surfaces.<br />

Permafleet ® Hi-TEC 680<br />

Climate Poster.<br />

The Climate Poster for Permafleet ®<br />

Hi-TEC 680 helps users choose the right<br />

WT additive in relation to local temperature<br />

and humidity.<br />

* Permafleet ®<br />

Hi-TEC 680 is to be<br />

launched soon.

Permafleet ® Hi-TEC 680 –<br />

system recommendation.<br />

The Permafleet ® paint system comes with the outstanding chemical and mechanical<br />

properties so important for commercial vehicles and multi-color finishes.<br />

This commercial vehicle paint can be applied in two different paint combinations:<br />

1. Top system wet-on-wet with Permafleet ® VHS Non-Sanding<br />

Surfacer 5620 and<br />

2. High-Class system with sanded HS Bus Surfacer 5530.<br />

For high-quality effect finishes, we recommend a final coat of HS Clear Coat<br />

8320/8330.<br />

Setting the<br />

tone.<br />

Substrates can be adapted<br />

to the base or top coat<br />

with the matching<br />

Permafleet ® surfacer color<br />

levels.<br />

With the white, light-grey and dark-grey<br />

color levels from <strong>Spies</strong> <strong>Hecker</strong>, the bodyshop<br />

improves the efficiency of its<br />

commercial vehicle finishing. By selecting<br />

the matching Permafleet ® surfacer<br />

ground color, it’s possible to enhance<br />

the hiding power of the base or top coat.<br />

But where do you find the color level?<br />

“The ground color is given on the can of<br />

the ready-mixed base coat or top coat,”<br />

explains Arno Steyns, <strong>Spies</strong> <strong>Hecker</strong> commercial<br />

vehicle specialist. “If you mix the<br />

color yourself in the bodyshop, the color<br />

level of the matching surfacer is indicated<br />

by the CRplus color software and in the<br />

ColorFinder on the Internet.”<br />

The desired opacity can be achieved with<br />

only 1.5 spray passes and thus saves material.<br />

“When painting commercial vehicles<br />

with their large surfaces, this really is<br />

a useful advantage,” says Arno Steyns.<br />

The color levels for Permafleet ® surfacer<br />

are available for the Permafleet ® Top Coat<br />

Series 630/670/675 and, as of October<br />

2012, for new Permafleet ® Hi-TEC 680<br />

Base Coat.<br />

19

20 <strong>colorexpert</strong><br />

Training camp.<br />

Alex Klassen, Daniel Plog and<br />

David Kloster jointly styled the<br />

iMiev at the <strong>Spies</strong> <strong>Hecker</strong> Center.<br />

Color<br />

Electrifying colors.<br />

“In six or seven years, we shall find that a new era of the motor car has dawned with<br />

the onset of electromobility,” says a convinced Oona Scheepers, Senior Designer<br />

Color & Trim at Volkswagen. At the IAA last year, the car manufacturer presented its<br />

new “E-Up!” model, whose very design is bolder, dynamic and looks almost futuristic.<br />

“We’re developing a color language specifically for electric cars. A technical silver blue<br />

as on the E-Up! and white stand for the electric drive.”<br />

Elke Dirks, Color Designer at DuPont Automotive OEM Coatings, has identified new<br />

trends. “Electric cars have to look both modern and eco-friendly. Ideally, the exterior<br />

color lends expression to the forward-looking ecological strategy.” In Europe, she believes,<br />

car makers are mostly going for satin metallics in light-colored, pastel shades<br />

evocative of nature. “These color effects are chosen to stress the close relationship<br />

between futuristic technology and nature – as with a frost effect, for example.” In this<br />

context, white is also considered an important “front color”. In Asia, “ice blue” is the<br />

key color symbolising the eco-generation. In the USA, on the other hand, fine metallic<br />

paintwork draws attention to the shift towards fuel- and emission-saving models.<br />

“How would you depict the future of<br />

electromobility in a paint finish?” This is<br />

the question put by <strong>Spies</strong> <strong>Hecker</strong> to upand-coming<br />

refinishers in a training project.<br />

What was wanted was an<br />

extra-creative finish for the white electrically<br />

powered i-MiEV compact car from<br />

Mitsubishi. “The suggestions were all<br />

very lively and imaginative, and we ultimately<br />

chose a blend of three of them,”<br />

says Dietmar Rausch, Manager of the<br />

<strong>Spies</strong> <strong>Hecker</strong> Center in Cologne, enthusiastically<br />

summing up the results of the<br />

project.<br />

From thorough substrate pre-treatment<br />

and elaborate design work through to<br />

the final clear coat, the trainees had two<br />

whole days to put their ideas into<br />

practice with expert equipment – and<br />

show what they had learnt so far. Most<br />

enjoyable of all, they claimed, was working<br />

on the details of the stylistic design<br />

elements and the shading. The white<br />

electric car is now adorned with multilayer<br />

printed circuit boards, plug sockets<br />

and plugs. The youngsters were absolutely<br />

delighted to be able to work at the<br />

<strong>Spies</strong> <strong>Hecker</strong> Center. A project that<br />

ought to spur them on for the rest of their<br />

training in their respective bodyshops.

Marketing<br />

Colorful characters.<br />

Are you a red type? Or more of a green? Colors are closely associated<br />

with personality types. The business owner can respond better to<br />

customers by using a color classification system.<br />

Whatever the task – dealing with complaints,<br />

negotiating a deal or attracting<br />

new customers – a good measure of<br />

sensitivity is always required. Understanding<br />

what makes people tick means<br />

identifying the personality type. At least<br />

this is the view of Frank M. Scheelen of<br />

SCHEELEN ® AG, a German firm devoted<br />

to management consultancy and diagnostics.<br />

“Personalities can be assigned<br />

to different basic types represented by<br />

the colors red, yellow, green and blue.”<br />

The colors stand for<br />

character types.<br />

“To accurately gauge the person you’re<br />

dealing with and to select the right conversation<br />

strategy, you have to analyse<br />

his or her appearance, body language<br />

and style of communication according to<br />

a certain color classification system.”<br />

Does he or she make a determined impression?<br />

If so, red is probably the matching<br />

personality type. Does the voice<br />

lack volume, and does the person seem<br />

hesitant? This may be a green type. For<br />

the bodyshop, this means the “red type”<br />

is a confident negotiator who loves to be<br />

served quickly. The “green type”, on the<br />

other hand is very reserved at first and<br />

demands more attention, understanding<br />

and patience. He or she wants above all<br />

else to have confidence in the bodyshop’s<br />

work.<br />

Targeted customer<br />

management.<br />

Sociable people belong to the yellow category.<br />

They tend to be amiable, humorous<br />

and optimistic. In talks with such<br />

customers, it’s useful to illustrate repairs<br />

and other services with colorful anecdotes.<br />

The “blue type” is different again. He<br />

or she tends to be critical and thorough.<br />

“Present your services without embellishment,”<br />

Scheelen advises. “The customer<br />

has to be able to immediately identify<br />

what’s in it for him. Describe the work<br />

precisely.”<br />

Finding the right language.<br />

Of course, people rarely conform completely<br />

to a single color type. Most people<br />

are a blend of all personality types. But<br />

anyone who studies other people closely<br />

can train himself to identify the dominant<br />

traits and those that are less pronounced.<br />

This takes the strain out of dealing with<br />

people, and the bodyshop can respond<br />

more effectively to the customer. This is<br />

professional customer management that<br />

builds confidence.<br />

Red type: – confident and direct. Clearly defined goals.<br />

Conversation strategy: get to the point without detours. Present neatly<br />

structured, accurately calculated price quotations. Arguments stressing<br />

the advantages are particularly important.<br />

Green type: – diffident and hesitant. Rarely speaks unless spoken to.<br />

Needs a lot of information to make a decision.<br />

Conversation strategy: what count here are trust and details. You<br />

should react understandingly and patiently to his or her reservations.<br />

Yellow type: – communicative and sociable. Humorous and optimistic.<br />

Usually takes decisions without deliberation.<br />

Conversation strategy: create a pleasant atmosphere, explain things<br />

with imagery. This way you can stimulate his or her enthusiasm.<br />

Blue type: – conscientious and critical. Inclined to see risks and dislikes<br />

change. Always looking for the best price/performance ratio.<br />

Conversation strategy: respond factually and thoughtfully and precisely<br />

explain how the customer benefits from the work you’ve suggested.<br />

21

22 <strong>colorexpert</strong><br />

Flying colors in China.<br />

BMW and <strong>Spies</strong> <strong>Hecker</strong> are working together<br />

in Asia as partners for superlative<br />

quality in vehicle refinishing. For the first<br />

BMW China Aftersales Painting Competition,<br />

the paint manufacturer from Cologne<br />

supported BMW AG in Shanghai.<br />

Professional refinishers from over 200<br />

dealerships in China attended the sevenmonth<br />

competition. The best twelve were<br />

selected for the final in Shanghai. “As a<br />

close partner to the BMW organisation,<br />

we were delighted to be able to support<br />

Eggs and<br />

bunnies galore!<br />

Swiss <strong>Spies</strong> <strong>Hecker</strong> customer Carrosserie<br />

Hug in Koppingen took on a special<br />

Easter mission. For local company Kofmel<br />

Kunststofftechnik AG, it painted<br />

oversized red Easter eggs and golden<br />

Easter bunnies – the bunnies alone were<br />

a metre tall and were used as advertising<br />

for the smaller chocolate originals.<br />

The Easter eggs were painted with the industrial<br />

coating system from <strong>Spies</strong> <strong>Hecker</strong>.<br />

The lettering and ornamentation<br />

under the clear coat were applied with<br />

great attention to detail by a graphics artist.<br />

In time for Passiontide, the two Easter<br />

symbols looked suitably festive in<br />

their colors and good enough to eat!<br />

the competition and introduce trade fair<br />

visitors to everything to do with professional<br />

paint application,” stresses Georg<br />

Tautz, Marketing & Strategy Manager<br />

<strong>Spies</strong> <strong>Hecker</strong> Asia Pacific.<br />

Li Cheng, <strong>Spies</strong> <strong>Hecker</strong> Sales Manager<br />

China, praised the team’s efforts: “Led by<br />

our Training Manager Louie Liu, we presented<br />

ourselves highly professionally to<br />

the market. I’m very proud of our team’s<br />

performance.”<br />

To crown the success of this involvement,<br />

Worldwide<br />

the first four places in the competition<br />

went to refinishers who use <strong>Spies</strong> <strong>Hecker</strong><br />

products.<br />

BMW attaches extra importance to waterborne<br />

base coat for professional refinishes,<br />

and the new patented technology<br />

of Permahyd ® Hi-TEC 480, launched in<br />

China in 2011, is establishing itself increasingly<br />

on the market. More and more bodyshops<br />

are using the efficient paint<br />

system. <strong>Spies</strong> <strong>Hecker</strong> is thus setting totally<br />

new standards in China as well.

Enter the dragon.<br />

Once upon a time, there was a dragon. Or, to be more precise,<br />

a dragon tattoo on the left arm of a famous Venezuelan baseball<br />

player who had played in all the world’s major leagues. And<br />

this player wanted nothing more than to have his 55 MTI<br />

powerboat with a top speed of a “mere” 320 km/h adorned<br />

with a spectacular paint finish. And he wanted the motif to be<br />

modelled on his tattoo. He found a suitable boatyard, Guardado<br />

Marine in Miami, where a graphic design was computergenerated,<br />

showing a multi-colored, fire-spewing dragon. But<br />

there was one major obstacle the project had to overcome: the<br />

shortage of time. The boat had to be launched in its terrific new<br />

outfit before the start of the new baseball season.<br />

To achieve the desired detail and vibrancy, nothing could be<br />

left to chance. So the Guardado team chose <strong>Spies</strong> <strong>Hecker</strong> Permasolid<br />

® SpectroFlex Surfacer 5400 and the Permacron ® Base<br />

Coat Series 293/295. “These products enable us to carry out<br />

our work – or rather, our artwork – just as we’d imagined it in<br />

our boldest dreams. The paint material has great coverage and<br />

dries incredibly fast,” stresses CEO Eduardo Guardado. The<br />

customer, at any rate, was absolutely knocked out by the finish.<br />

So everyone lived happily ever after. That is, after seven<br />

weeks of highly intricate body and paint work. Ten craftsmen<br />

were involved overall. And the baseball player? He’s now under<br />

contract in Japan – the land famed for its dragon myths.<br />

A change of gear.<br />

When he paints racing bikes, Frank<br />

Hoste is in his element. The Belgian has<br />

been the owner of a cycle workshop<br />

since 1991, before which he was a professional<br />

road cycle racer for many<br />

years. Along with numerous victories in<br />

national and international cycle races, he<br />

took part in the Tour de France eight<br />

times and won five stages. One of the<br />

biggest achievements of his career was<br />

winning the Green Jersey during the<br />

1984 Tour. In his shop, he now handles<br />

frames among other things for the Belgian<br />

professional cycling team, but also<br />

for private customers. “For instance, we<br />

can create a modern and unique design<br />

for an old bike so that it looks like new,”<br />

Frank Hoste explains. He uses <strong>Spies</strong> <strong>Hecker</strong><br />

products because he appreciates<br />

their simple application and extra quality.<br />

For Frank Hoste, it’s always an exciting<br />

challenge to use innovative technology<br />

and incorporate current trends. For<br />

example, he combines different effects<br />

such as matt and gloss or light colors<br />

with a special carbon fibre look. And<br />

what is it that he likes about his job?<br />

“Being creative and innovative. No two<br />

projects are the same. Cycle jobs are always<br />

highly individualistic.” Road cycle<br />

racing is still Frank Hoste’s great passion.<br />

Which is why he’s only too happy to<br />

act as a commentator on radio and television<br />

during the Tour de France. A<br />

hobby that’s the perfect foil to his work.<br />

23

Our refinishers aim<br />

for long partnerships.<br />

Our partner bodyshops have come to rely on balanced product systems,<br />

high color accuracy, outstanding finishes and efficient service.<br />

We help them with their challenging projects.<br />

Because together we achieve more.<br />

<strong>Spies</strong> <strong>Hecker</strong> – simply closer.<br />

<strong>Spies</strong> <strong>Hecker</strong> GmbH · Horbeller Straße 17 · 50858 Köln · www.spieshecker.de