Effect of Automatic Sprinkler Protection on Smoke Control Systems

Effect of Automatic Sprinkler Protection on Smoke Control Systems

Effect of Automatic Sprinkler Protection on Smoke Control Systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

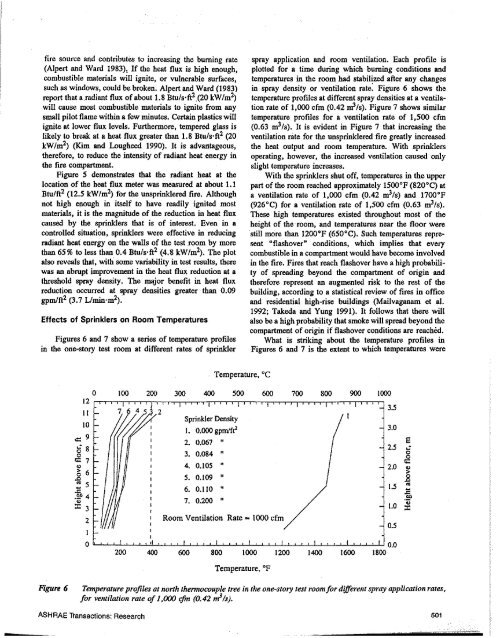

fire source and c<strong>on</strong>tributes to increasing the burning rate(Alpert attd Ward 1983), If the heat flux is high enough,combustible materials will ignite, or vulnerable surfaces,such as windows, could be broken. Alpert and Ward (1983)report that a.radiant flux <str<strong>on</strong>g>of</str<strong>on</strong>g> about 1.8 Btu/s·ft 2 (20 kW/ru 2 )will cause most combustible materials to ignite from anysmall pilot flame within a few minutes. Certain plastics willignite at lower flux levels. Furthermore, tempered glass islikely to break at a heat flux greater than 1.8 Btu/s·ft 2 (20kW/m2) (Kim and Lougheed 1990). It is advantageous,therefore, to reduce the intensity <str<strong>on</strong>g>of</str<strong>on</strong>g> radiant heat energy inthe fire compartment.Figure 5 dem<strong>on</strong>strates that the radiant heat at thelocati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the heat flux meter was measured at about 1.1Btuift 2 (12.5 kW im 2 ) for the unsprinklered fire. Althoughnot high enough in itself to have readily ignited mostmaterials, it is the magnitude <str<strong>on</strong>g>of</str<strong>on</strong>g> the reducti<strong>on</strong> in heat fluxcaused by the sprinklers that is <str<strong>on</strong>g>of</str<strong>on</strong>g> interest. Even in ac<strong>on</strong>trolled situati<strong>on</strong>, sprinklers were effective in reducingradiant heat energy <strong>on</strong> the walls <str<strong>on</strong>g>of</str<strong>on</strong>g> the test .room by morethan 65% to less than 0.4 Btu/s·ft2 (4.8 kW/m2). The plotalso reveals that, with some variability in test results, therewas an abrupt improvement in the heat flux reducti<strong>on</strong> at athreshold spray density. The major benefit in heat fluxreducti<strong>on</strong> occurred at spray densities greater than 0.09gpmift 2 (3.7 L/min·m 2 ).<str<strong>on</strong>g>Effect</str<strong>on</strong>g>s <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Sprinkler</str<strong>on</strong>g>s <strong>on</strong> Room TemperaturesFigures 6 and 7 show a series <str<strong>on</strong>g>of</str<strong>on</strong>g> temperature pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ilesin the <strong>on</strong>e-story test room at different rates <str<strong>on</strong>g>of</str<strong>on</strong>g> sprinklerspray applicati<strong>on</strong> and room ventilati<strong>on</strong>. Each pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile isplotted for a time during which burning c<strong>on</strong>diti<strong>on</strong>s andtemperatures in the room had stabilized after any changesin spray density or ventilati<strong>on</strong> rate: Figure 6 shows thetemperature pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles at different spray densities at a ventilati<strong>on</strong>rate <str<strong>on</strong>g>of</str<strong>on</strong>g> 1,000 cfm (0.42 rri'is). Figure 7 shows similartemperature pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles for a ventilati<strong>on</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> 1,500 cfm(0.63 m 3 /s). It is evident in Figure 7 that increasing theventilati<strong>on</strong> rate for the unsprinklered fire greatly increasedthe heat output and room temperature. With sprinklersoperating, however, the increased ventilati<strong>on</strong> caused <strong>on</strong>lyslight temperature increases.With the sprinklers shut <str<strong>on</strong>g>of</str<strong>on</strong>g>f, temperatures in the upperpart <str<strong>on</strong>g>of</str<strong>on</strong>g> the room reached approximately 1500•F (820°C) ata ventilati<strong>on</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> 1,000 cfm (0.42 m 3 /s) and 1700°F(926°C) for a ventilati<strong>on</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> 1,500 cfm (0.63 m 3 /s).These high temperatures existed throughout most <str<strong>on</strong>g>of</str<strong>on</strong>g> theheight <str<strong>on</strong>g>of</str<strong>on</strong>g> the room, and temperatures near the floor were·still more than 1200•F (650°C), Such temperatures represent"flashover" c<strong>on</strong>diti<strong>on</strong>s, which implies that everycombustible in a compartment would have become involvedin the fire. Fires that reach flashover have a high probability<str<strong>on</strong>g>of</str<strong>on</strong>g> spreading bey<strong>on</strong>d the compartment <str<strong>on</strong>g>of</str<strong>on</strong>g> origin andtherefore represent an augmented risk to the rest <str<strong>on</strong>g>of</str<strong>on</strong>g> thebuilding, according to a statistical review <str<strong>on</strong>g>of</str<strong>on</strong>g> fires in <str<strong>on</strong>g>of</str<strong>on</strong>g>ficeand residential high-rise buildings (Mailvaganam et a!.1992; Takeda and Yung 1991). It follows that there willalso be a high probability that smoke will spread bey<strong>on</strong>d thecompartment <str<strong>on</strong>g>of</str<strong>on</strong>g> origin if flashover c<strong>on</strong>diti<strong>on</strong>s are reached.What is striking about the temperature pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles inFigures 6 and 7 is the extent to which temperatures wereTemperature, •c0 100 200 300 400 500 600 700 800 900 1000123.5II2<str<strong>on</strong>g>Sprinkler</str<strong>on</strong>g> Density10I . 0.000 gpm/ft 2 3.0.::::92. 0.067 " E.: 8 2.5 .:3. 0.084 0 " 0..: 7c4. 0.105> "2.06 " >"0.. s . 0.109 " 5.81.5...0.E 6 . 0.110 ".2!' 4-..c7. ·;:;:I: " 3 1.0 :I:2 Room Ventilati<strong>on</strong> Rate- 1000 cfm0.5I0.200 "..0 0.0200 400 600 800 1000 1200 1400 1600 1800Temperature, •FFigure 6Temperature pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles at north thermocouple tree in the <strong>on</strong>e-story test room for different spray applicati<strong>on</strong> rates,for ventilati<strong>on</strong> rate <str<strong>on</strong>g>of</str<strong>on</strong>g> 1,000 cfm (0.42 m 3 Is).ASHRAE Transacti<strong>on</strong>s: Research 501