Effect of Automatic Sprinkler Protection on Smoke Control Systems

Effect of Automatic Sprinkler Protection on Smoke Control Systems

Effect of Automatic Sprinkler Protection on Smoke Control Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

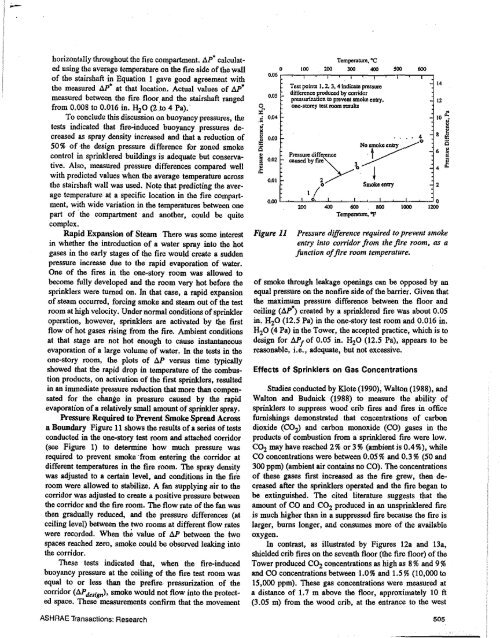

horiz<strong>on</strong>tally throughout the fire compartment. AP" calculatedusing the average temperature <strong>on</strong> the fire side <str<strong>on</strong>g>of</str<strong>on</strong>g> the wall<str<strong>on</strong>g>of</str<strong>on</strong>g> the stairshaft in Equati<strong>on</strong> I gave good agreement withthe measured AP• at that locati<strong>on</strong>. Actual values <str<strong>on</strong>g>of</str<strong>on</strong>g> AP•measured between the fire floor and the stairshaft rangedfrom 0.008 to 0.016 in. H 2 0 (2 .to 4 Pa).To c<strong>on</strong>clude this discussi<strong>on</strong> <strong>on</strong> buoyancy pressures, thetests indicated that fire-induced buoyancy pressures decreasedas spray density increased and that a reducti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g>50% <str<strong>on</strong>g>of</str<strong>on</strong>g> the design pressure difference for z<strong>on</strong>ed smokec<strong>on</strong>trol in sprinklered buildings is adequate but c<strong>on</strong>servative.Also, measured pressure differences compared wellwith predicted values when the average temperature acrossthe stairshaft wall was used. Note that predicting the averagetemperature at a specific locati<strong>on</strong> in the fire compartment,with wide variati<strong>on</strong> in the temperatures between <strong>on</strong>epart <str<strong>on</strong>g>of</str<strong>on</strong>g> ·the compartment and another, could be quitecomplex.Rapid Expansi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Steam There was some interestin whether the introducti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a water spray into the hotgases in the early stages <str<strong>on</strong>g>of</str<strong>on</strong>g> the fire would create a suddenpressure increase due to the rapid evaporati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> water.One <str<strong>on</strong>g>of</str<strong>on</strong>g> the fires in the <strong>on</strong>e-story room was allowed tobecome fully developed and the room very hot before thesprinklers were turned <strong>on</strong>. In that case, a rapid expansi<strong>on</strong><str<strong>on</strong>g>of</str<strong>on</strong>g> steam occurred, forcing smoke and steam out <str<strong>on</strong>g>of</str<strong>on</strong>g> the testroom at high velocity. Under normal c<strong>on</strong>diti<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> sprinkleroperati<strong>on</strong>, however, sprinklers are activated by the firstflow <str<strong>on</strong>g>of</str<strong>on</strong>g> hot gases rising from the fire. Ambient c<strong>on</strong>diti<strong>on</strong>sat that stage are not hot enough to cause instantaneousevaporati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a large volume <str<strong>on</strong>g>of</str<strong>on</strong>g> water. In the tests in the<strong>on</strong>e-story room, the plots <str<strong>on</strong>g>of</str<strong>on</strong>g> AP versus time typicallyshowed that the rapid drop in temperature <str<strong>on</strong>g>of</str<strong>on</strong>g> the combusti<strong>on</strong>products, <strong>on</strong> activati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the first sprinklers, resultedin an immediate pressure reducti<strong>on</strong> that more than compensatedfor the change in pressure caused by the rapidevaporati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a relatively small amount <str<strong>on</strong>g>of</str<strong>on</strong>g> sprinkler spray.Pressure Required to Prevent <strong>Smoke</strong> Spread Acrossa Boundary Figure II shows the results <str<strong>on</strong>g>of</str<strong>on</strong>g> a series <str<strong>on</strong>g>of</str<strong>on</strong>g> testsc<strong>on</strong>ducted in the <strong>on</strong>e-story test room and attached corridor(see Figure I) to determine how much pressure wasrequired to prevent smoke ·from entering the corridor atdifferent temperatures in the fire room. The spray densitywas adjusted to a certain level, and c<strong>on</strong>diti<strong>on</strong>s in the fireroom were allowed to stabilize. A fan supplying air to thecorridor was adjusted to create a positive pressure betweenthe corridor and the fire room. The flow rate <str<strong>on</strong>g>of</str<strong>on</strong>g> the fan wasthen gradually reduced, and the pressure differences (atceiling level) between the two rooms at different flow rateswere recorded. When the value <str<strong>on</strong>g>of</str<strong>on</strong>g> AP between the twospaces reached zero, smoke could be observed leaking intothe corridor.These tests indicated that, when the fire-inducedbuoyancy pressure at the ceiling <str<strong>on</strong>g>of</str<strong>on</strong>g> the fire test room wasequal to or less than the prefire pressurizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> thecorridor (AP d.sign), smoke would not flow into the protectedspace. These measurements c<strong>on</strong>firm that the movementTemperature, oc0 100 200 300 400 soo 6000.06 .-~...,-~-,.-.-..-~-..-.~...,--,...--.--,0.0.5~.5 0.04 -~ 0.03cI0.02O.otTest points I, 2, 3, 4 indicate pressure -14difference produced by corridorpressurizati<strong>on</strong> to prevent smoke entry,- 12<strong>on</strong>e~storey test room results.....10 c:-•0smoke entryP«ssure diffe)v~t~11!c• eil~- 4causod by fuc'\,2 . !o <strong>Smoke</strong> entry 2'•/omL-~~200L-~-... ~_. __ 600L-~-800~~~,ooo~_.~,~Figure 11Temperature. opPressure difference required to prevent smokeentry into corridor from the fire room, as afuncti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> fire room temperature.<str<strong>on</strong>g>of</str<strong>on</strong>g> smoke through leakage openings can be opposed by anequal pressure <strong>on</strong> the n<strong>on</strong>fire side <str<strong>on</strong>g>of</str<strong>on</strong>g> the barrier. Given thatthe maximum pressure difference between the floor andceiling (AP•) created by a sprinklered fire was about 0.05in. H 2 0 (12.5 Pa) in the <strong>on</strong>e-story test room and 0.016 in.H 2 0 (4 Pa) in the Tower, the accepted practice, which is todesign for AP 1<str<strong>on</strong>g>of</str<strong>on</strong>g> 0.05 in. H 2 0 (12.5 Pa), appears to bereas<strong>on</strong>able, i.e., adequate, but not excessive.<str<strong>on</strong>g>Effect</str<strong>on</strong>g>s <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Sprinkler</str<strong>on</strong>g>s <strong>on</strong> Gas C<strong>on</strong>centrati<strong>on</strong>sStudies c<strong>on</strong>ducted by Klote (1990), Walt<strong>on</strong> (1988), andWalt<strong>on</strong> and Budnick (1988) to measure the ability <str<strong>on</strong>g>of</str<strong>on</strong>g>sprinklers to suppress wood crib fires and fires in <str<strong>on</strong>g>of</str<strong>on</strong>g>ficefurnishings dem<strong>on</strong>strated that c<strong>on</strong>centrati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> carb<strong>on</strong>dioxide (COz) and carb<strong>on</strong> m<strong>on</strong>oxide (CO) gases in theproducts <str<strong>on</strong>g>of</str<strong>on</strong>g> combusti<strong>on</strong> from a sprinklered fire were low.C0 2 may have reached 2% or 3% (ambient is 0.4% ), whileCO c<strong>on</strong>centrati<strong>on</strong>s were between 0.05% and 0.3% (50 and300 ppm) (ambient air c<strong>on</strong>tains no CO). The c<strong>on</strong>centrati<strong>on</strong>s<str<strong>on</strong>g>of</str<strong>on</strong>g> these gases first increased as the fire grew, then decreasedafter the sprinklers operated and the fire began tobe extinguished. The cited literature suggests that theamount <str<strong>on</strong>g>of</str<strong>on</strong>g> CO and C0 2 produced in an unsprinklered fireis much higher than in a suppressed fire because the fire islarger, bums l<strong>on</strong>ger, and c<strong>on</strong>sumes more <str<strong>on</strong>g>of</str<strong>on</strong>g> the availableoxygen.In c<strong>on</strong>trast, as illustrated by Figures 12a and 13a,shielded crib fires <strong>on</strong> the seventh floor (the fire floor) <str<strong>on</strong>g>of</str<strong>on</strong>g> theTower produced C0 2 c<strong>on</strong>centrati<strong>on</strong>s as high as 8% and 9%and CO c<strong>on</strong>centrati<strong>on</strong>s between 1.0% and !.5% (10,000 to15,000 ppm). These gas c<strong>on</strong>centrati<strong>on</strong>s were measured ata distance <str<strong>on</strong>g>of</str<strong>on</strong>g> 1.7 m above the floor, approximately 10. ft(3.05 m) from the wood crib, at the entrance to the west'ASHRAE Transacti<strong>on</strong>s: Research505