Ipressurized z<strong>on</strong>e before opening door F7. This failure toprevent smoke spread into the stairshaft indicates that thestrategy <str<strong>on</strong>g>of</str<strong>on</strong>g> not actively pressurizing the stairshaft in thesame way as other z<strong>on</strong>es to be protected, but relying <strong>on</strong> themechanical exhaust <str<strong>on</strong>g>of</str<strong>on</strong>g> the fire floor to hold the smoke <strong>on</strong>the fire floor, does not reliably protect the stairshaft againstsmoke entry. Given that smoke spread occurred underc<strong>on</strong>diti<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> sprinklered fires, in spite <str<strong>on</strong>g>of</str<strong>on</strong>g> low tempemturesand low buoyancy pressures and full pressurizati<strong>on</strong> toAPdesign = 0.1 in. H20 (25 Pa), it is certain that smokefrom a n<strong>on</strong>sprinklered fire would also spread into thestairshaft under open-door c<strong>on</strong>diti<strong>on</strong>s.Two tests were c<strong>on</strong>ducted with no z<strong>on</strong>ed smoke c<strong>on</strong>trolfeatures in effect, i.e., with AP desl 8n = 0. The first <str<strong>on</strong>g>of</str<strong>on</strong>g> thesetests involved an unshielded wood crib, in which the firewas extinguished in less than 12 minutes at a sprinklerdensity <str<strong>on</strong>g>of</str<strong>on</strong>g> 0.13 gpm!ft2 (5.3 L/minrn 2 ). A small amount<str<strong>on</strong>g>of</str<strong>on</strong>g> smoke did spread through interz<strong>on</strong>al leakage openingsinto the floor above the fire floor and into the stairshaftwhen the door was opened. The total amount <str<strong>on</strong>g>of</str<strong>on</strong>g> smokeproduced by the short-dumti<strong>on</strong> fire was low, and temperaturesand gas c<strong>on</strong>centrati<strong>on</strong>s outside the fire floor did notreach dangerous levels. For the case <str<strong>on</strong>g>of</str<strong>on</strong>g> an unshielded fire,then, with no other smoke c<strong>on</strong>trol features in effect, thesprinkler system performed as a successful smoke c<strong>on</strong>trolmeasure. This test supports the established expectati<strong>on</strong> that,for unshielded fires, sprinklers provide a sufficient level <str<strong>on</strong>g>of</str<strong>on</strong>g>safety against smoke hazards in high buildings.The sec<strong>on</strong>d test with a shielded wood crib, with noz<strong>on</strong>ed smoke c<strong>on</strong>trol features in effect, did not performnearly as well. Because <str<strong>on</strong>g>of</str<strong>on</strong>g> the prol<strong>on</strong>ged burning <str<strong>on</strong>g>of</str<strong>on</strong>g> thefire,. a large volume <str<strong>on</strong>g>of</str<strong>on</strong>g> smoke was produced. The smokewas high in CO c<strong>on</strong>tent ( > 4,000 ppm) and thereforedangerous. <strong>Smoke</strong> spread to floors above the fire floorthrough leakage openings before the stair door was openedand into the stairshaft when the door was opened. Thestairshaft became smokelogged within minutes <str<strong>on</strong>g>of</str<strong>on</strong>g> openingthe door, with complete loss <str<strong>on</strong>g>of</str<strong>on</strong>g> visibility and tempemtures<str<strong>on</strong>g>of</str<strong>on</strong>g> more than 150°F (65°C), These c<strong>on</strong>diti<strong>on</strong>s were c<strong>on</strong>sidereduntenable. This test clearly dem<strong>on</strong>stmted that smokeproduced by a shielded. fire represents a serious threat tolife safety. Unless measures are taken to c<strong>on</strong>fine the smoketo the fire floor, smoke will spread through the building.<str<strong>on</strong>g>Effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Sprinkler</str<strong>on</strong>g>s <strong>on</strong> <strong>Smoke</strong> Producti<strong>on</strong>It is sometimes argued that sprinklers increase theamount <str<strong>on</strong>g>of</str<strong>on</strong>g> smoke produced in a fire. The shielded, sustainedfires in this series <str<strong>on</strong>g>of</str<strong>on</strong>g> tests produced large volumes <str<strong>on</strong>g>of</str<strong>on</strong>g>smoke. It is a moot point, however, as to how much moresmoke would have been produced if the fires had not beenrestmined. For an unshielded fire, the sprinklers are usuallysuccessful in extinguishing the fire, which then stops smokeproducti<strong>on</strong>. For a shielded fire, the fuel bums in wetc<strong>on</strong>diti<strong>on</strong>s at a reduced burning mte. It is impossible to sayfrom data collected in these tests whether the actual massproducti<strong>on</strong> mte <str<strong>on</strong>g>of</str<strong>on</strong>g> soot and other products <str<strong>on</strong>g>of</str<strong>on</strong>g> combusti<strong>on</strong>ASH RAE Transacti<strong>on</strong>s: Researchwas greater when the sprinklers were operating. There isevidence, however, from at least <strong>on</strong>e <str<strong>on</strong>g>of</str<strong>on</strong>g> the Tower tests,that smoke density in the exhaust shaft increased when thesprinklers were shut <str<strong>on</strong>g>of</str<strong>on</strong>g>f. It is believed that this increase wasdue to increased smoke producti<strong>on</strong> as the fire regrew,became hotter, and involved more fuel.Based <strong>on</strong> the observati<strong>on</strong>s in the tests in the <strong>on</strong>e-storyroom and the Tower, it is noted that the fire itself is theactual source <str<strong>on</strong>g>of</str<strong>on</strong>g> smoke. Reducing the burning rate <str<strong>on</strong>g>of</str<strong>on</strong>g> a fireby applicati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> sprinkler spray reduces the total producti<strong>on</strong><str<strong>on</strong>g>of</str<strong>on</strong>g> smoke. However, the injecti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> sprinkler spmy. into the hot gases coming from a fire creates steam, whichdisrupts the flow <str<strong>on</strong>g>of</str<strong>on</strong>g> the gases in the hot layer. The turbulencecreated by the mpid cooling <str<strong>on</strong>g>of</str<strong>on</strong>g> the hot gases and theexpansi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> steam deepens the smoke layer, even dmwingceiling gases down to floor level. The optical properties <str<strong>on</strong>g>of</str<strong>on</strong>g>the smoke and steam mixture are such that visibility ismpidly reduced at lower levels in the room. These rapidchanges in smoke-layer depth and visibility brought aboutby sprinkler opemti<strong>on</strong> do not necessarily mean that the mte<str<strong>on</strong>g>of</str<strong>on</strong>g> producti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> smoke has increased, however.A mpid reducti<strong>on</strong> in visibility in the immediate vicinity<str<strong>on</strong>g>of</str<strong>on</strong>g> the fire when sprinklers activate may have negativeimplicati<strong>on</strong>s for pers<strong>on</strong>s exiting the fire floor. However, ifa fire is allowed to c<strong>on</strong>tinue to grow, visibility and temperaturec<strong>on</strong>diti<strong>on</strong>s will sb<strong>on</strong> become unacceptable within aneven larger area <strong>on</strong> the fire floor and bey<strong>on</strong>d. Therefore,the negative aspect <str<strong>on</strong>g>of</str<strong>on</strong>g> reduced visibility in a small areashould be viewed in the c<strong>on</strong>text <str<strong>on</strong>g>of</str<strong>on</strong>g> the benefit <str<strong>on</strong>g>of</str<strong>on</strong>g> eliminati<strong>on</strong><str<strong>on</strong>g>of</str<strong>on</strong>g> the fire threat to a much larger area.The <strong>on</strong>e-story test room used for some <str<strong>on</strong>g>of</str<strong>on</strong>g> these testswas located inside the Bum Hall, which is a very largespace similar to an atrium. During severn! tests in which thecapacity <str<strong>on</strong>g>of</str<strong>on</strong>g> the collector hood was surpassed, it wasobserved that the smoke from the sprinklered fires did notrise to the 40 ft (13 m) high ceiling <str<strong>on</strong>g>of</str<strong>on</strong>g> the Bum Hall.Instead, the smoke accumulated at floor level, leaving theupper porti<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> the Bum Hall clear.IMPLICATIOIIIS FOR DESIGN OFZONED SMOKE CONTROL SYSTEMSThe purpose <str<strong>on</strong>g>of</str<strong>on</strong>g> these experiments was to investigate theeffects <str<strong>on</strong>g>of</str<strong>on</strong>g> automatic sprinklers <strong>on</strong> the c<strong>on</strong>diti<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> heatrelease mte, temperature, pressure, and levels <str<strong>on</strong>g>of</str<strong>on</strong>g> oxygen,carb<strong>on</strong> dioxide, and carb<strong>on</strong> m<strong>on</strong>oxide in a building underfire c<strong>on</strong>diti<strong>on</strong>s and to assess the effect that changes in thesec<strong>on</strong>diti<strong>on</strong>s might have <strong>on</strong> the performance <str<strong>on</strong>g>of</str<strong>on</strong>g> a z<strong>on</strong>ed smokeCOI)trol system. The results <str<strong>on</strong>g>of</str<strong>on</strong>g> the test progmm haveimplicati<strong>on</strong>s for the design <str<strong>on</strong>g>of</str<strong>on</strong>g> z<strong>on</strong>ed smoke c<strong>on</strong>trol systemsin sprinklered buildings. These implicati<strong>on</strong>s are summarizedhere.1. <str<strong>on</strong>g>Sprinkler</str<strong>on</strong>g>s have a good record <str<strong>on</strong>g>of</str<strong>on</strong>g> reliability in c<strong>on</strong>trollingfires and, by limiting the amount <str<strong>on</strong>g>of</str<strong>on</strong>g> combustiblesinvolved in a fire, also restrict smoke producti<strong>on</strong>. Asit c<strong>on</strong>stitutes both a detecti<strong>on</strong> system and a fire-fighting509

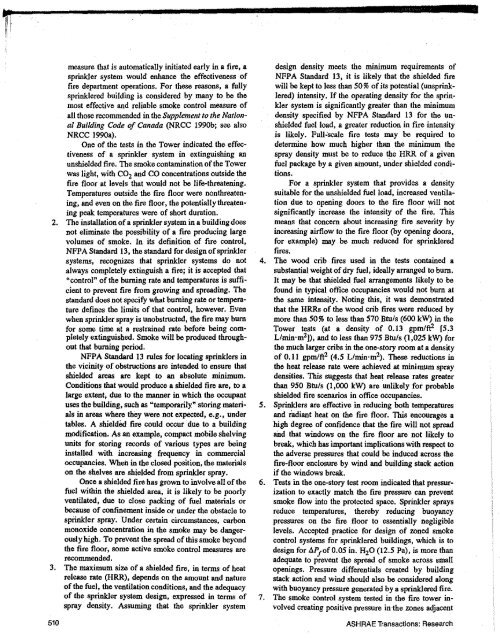

measure that is automatically initiated early in a fire, asprinkler system would enhance the effectiveness <str<strong>on</strong>g>of</str<strong>on</strong>g>fire department operati<strong>on</strong>s. For these reas<strong>on</strong>s, a fullysprinklered building is c<strong>on</strong>sidered by many to be themost effective and reliable smoke c<strong>on</strong>trol measure <str<strong>on</strong>g>of</str<strong>on</strong>g>all those recommended in the Supplement to the Nati<strong>on</strong>alBuilding Code <str<strong>on</strong>g>of</str<strong>on</strong>g> Canada (NRCC !990b; see alsoNRCC 1990a).One <str<strong>on</strong>g>of</str<strong>on</strong>g> the tests in the Tower indicated the effectiveness<str<strong>on</strong>g>of</str<strong>on</strong>g> a sprinkler system in extinguishing anunshielded fire. The smoke c<strong>on</strong>taminati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the Towerwas light, with C0 2 and CO c<strong>on</strong>centrati<strong>on</strong>s outside thefire floor at levels that would not be life-threatening.Temperatures outside the fire floor were n<strong>on</strong>threatening,and even <strong>on</strong> the fire floor, the potentially threateningpeak temperatures were <str<strong>on</strong>g>of</str<strong>on</strong>g> short durati<strong>on</strong>.2. The installati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a sprinkler system in a building doesnot eliminate the possibility <str<strong>on</strong>g>of</str<strong>on</strong>g> a fire producing largevolumes <str<strong>on</strong>g>of</str<strong>on</strong>g> smoke. In its definiti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> fire c<strong>on</strong>trol,NFP A Standard 13, the standard for design <str<strong>on</strong>g>of</str<strong>on</strong>g> sprinklersystems, recognizes that sprinkler systems do notalways completely extinguish a fire; it is accepted that"c<strong>on</strong>trol" <str<strong>on</strong>g>of</str<strong>on</strong>g> the burning rate and temperatures is sufficientto prevent fire from growing and spreading. Thestandard does not specify what burning rate or temperaturedefines the limits <str<strong>on</strong>g>of</str<strong>on</strong>g> that c<strong>on</strong>trol, however. Evenwhen sprinkler spray is unobstructed, the fire may burnfor some time at a restrained rate before being completelyextinguished. <strong>Smoke</strong> will be produced throughoutthat burning period.NFPA Standard 13 rules for locating sprinklers inthe vicinity <str<strong>on</strong>g>of</str<strong>on</strong>g> obstructi<strong>on</strong>s are intended to ensure thatshielded areas are kept to an absolute minimum.C<strong>on</strong>diti<strong>on</strong>s that would produce a shielded fire are, to alarge extent, due to the manner in which the occupantuses the building, such as "temporarily" storing materialsin areas where they were not expected, e.g., undertables. A shielded fire could occur due to a buildingmodificati<strong>on</strong>. As an example, compact mobile shelvingunits for storing recorda <str<strong>on</strong>g>of</str<strong>on</strong>g> various types are beinginstalled with increasing frequency in commercialoccupancies. When in the closed positi<strong>on</strong>, the materials<strong>on</strong> the shelves are shielded from sprinkler spray.Once a shielded fire bas grown to involve all <str<strong>on</strong>g>of</str<strong>on</strong>g> thefuel within the shielded area, it is likely to be poorlyventilated, due to close packing <str<strong>on</strong>g>of</str<strong>on</strong>g> fuel materials orbecause <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>fmement inside or under the obstacle tosprinkler spray. Under certain circumstances, carb<strong>on</strong>m<strong>on</strong>oxide c<strong>on</strong>centrati<strong>on</strong> in the smoke may be dangerouslyhigh. To prevent the spread <str<strong>on</strong>g>of</str<strong>on</strong>g> this smoke bey<strong>on</strong>dthe fire floor, some active smoke c<strong>on</strong>trol measures arerecommended.3. The maximum size <str<strong>on</strong>g>of</str<strong>on</strong>g> a shielded fire, in terms <str<strong>on</strong>g>of</str<strong>on</strong>g> heatrelease rate (HRR), depends <strong>on</strong> the amount and natore<str<strong>on</strong>g>of</str<strong>on</strong>g> the fuel, the ventilati<strong>on</strong> c<strong>on</strong>diti<strong>on</strong>s, and the adequacy<str<strong>on</strong>g>of</str<strong>on</strong>g> the sprinkler system design, expressed in terms <str<strong>on</strong>g>of</str<strong>on</strong>g>spray density. Assuming that the sprinkler system510design density meets the minimum requirements <str<strong>on</strong>g>of</str<strong>on</strong>g>NFPA Standard 13, it is likely that the shielded firewill be kept to less than 50% <str<strong>on</strong>g>of</str<strong>on</strong>g> its potential (unsprinklered)intensity. If the operating density for the sprinklersystem is significantly greater than the minimumdensity specified by NFPA Standard 13 for the unshieldedfuel load, a greater reducti<strong>on</strong> in fire intensityis likely. Full"scale fire tests may be required todetermine bow much higher than the minimum thespray density must be to reduce the HRR <str<strong>on</strong>g>of</str<strong>on</strong>g> a givenfuel package by a given amount, under shielded c<strong>on</strong>diti<strong>on</strong>s.For a sprinkler system that provides a densitysuitable for the unshielded fuel load, increased ventilati<strong>on</strong>due to opening doors to the fire floor will notsignificantly increase the intensity <str<strong>on</strong>g>of</str<strong>on</strong>g> the fire. Thismeans that c<strong>on</strong>cern about increasing fire severity byincreasing airflow to the fire floor (by opening doors,for example) may be much reduced for sprinkleredfires.4. The wood crib fires used in the tests c<strong>on</strong>tained asubstantial weight <str<strong>on</strong>g>of</str<strong>on</strong>g> dry fuel, ideally arranged to burn.It may be that shielded fuel arrangements likely to befound in typical <str<strong>on</strong>g>of</str<strong>on</strong>g>fice occupancies would not bum atthe same intensity. Noting this, it was dem<strong>on</strong>stratedthat the HRRs <str<strong>on</strong>g>of</str<strong>on</strong>g> the wood crib fires were reduced bymore than 50% to less than S70 Btu/s (600 kW) in theTower tests (at a density <str<strong>on</strong>g>of</str<strong>on</strong>g> 0.13 gpmlft2 [53Llmin·m 2 ]), and to less than 97S Btuls (l,02S kW) forthe much larger cribs in the <strong>on</strong>e-story room at a density<str<strong>on</strong>g>of</str<strong>on</strong>g> 0.11 gpmlft 2 (4.S L/min·m2). These reducti<strong>on</strong>s inthe beat release rate were achieved at minim11m spraydensities. This suggests that heat release rates greaterthan 950 Btu/s (1,000 kW) are unlikely for probableshielded fire scenarios in <str<strong>on</strong>g>of</str<strong>on</strong>g>fice occupancies.S. <str<strong>on</strong>g>Sprinkler</str<strong>on</strong>g>s are effective in reducing both temperatoresand iadiant heat <strong>on</strong> the fire floor. This encourages ahigh degree <str<strong>on</strong>g>of</str<strong>on</strong>g> c<strong>on</strong>fidence that the fire will not spreadand that windows <strong>on</strong> the fire floor are not likely tobreak, which bas important implicati<strong>on</strong>s with respect tothe adverse pressures that could be induced across thefire-floor enclosure by wind and building stack acti<strong>on</strong>if the windows break.6. Tests in the <strong>on</strong>e-story test room indicated that pressurizati<strong>on</strong>to exactly match the fire pressure can preventsmoke flow into the protected space. <str<strong>on</strong>g>Sprinkler</str<strong>on</strong>g> spraysreduce temperatures, thereby reducing buoyancypressures <strong>on</strong> the fire floor to essentially negligiblelevels. Accepted practice for design <str<strong>on</strong>g>of</str<strong>on</strong>g> z<strong>on</strong>ed smokec<strong>on</strong>trol systems for sprinklered buildings, which is todesign for fl.P <str<strong>on</strong>g>of</str<strong>on</strong>g>0.05 1in. H 2 0 (12.5 Pa), is more thanadequate to prevent the spread <str<strong>on</strong>g>of</str<strong>on</strong>g> smoke across smallopenings. Pressure differentials created by buildingstack acti<strong>on</strong> and wind should also be c<strong>on</strong>sidered al<strong>on</strong>gwith buoyancy pressure generated by a sprinklered fire.7. The smoke c<strong>on</strong>trol system tested in the fire tower involvedcreating positive pressure in ·the z<strong>on</strong>es adjacentASH RAE Transacti<strong>on</strong>s: Research