GOOD FOOD, EVERY DAYâ„¢ H.J. Heinz Company

GOOD FOOD, EVERY DAYâ„¢ H.J. Heinz Company

GOOD FOOD, EVERY DAYâ„¢ H.J. Heinz Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

36 | HEINZ Corporate Social Responsibility Report 2005<br />

Environmental Performance Measures<br />

The success of EMS is monitored by Environmental Performance Measures (EPMs) that<br />

track facility input vs. output. We are continuously seeking and finding ways to reduce our<br />

basic manufacturing inputs (water, electricity, fuels and packaging material) to optimize<br />

the amount of raw materials we require in our manufacturing and to reduce the amount<br />

of waste generated.<br />

The EPMs focus on utilities and energy usage relative to finished production volume for<br />

the following:<br />

• Water — As an essential ingredient in food manufacturing, water usage is critical.<br />

However, we continue to look for new and innovative ways to decrease usage.<br />

(See Page 34 on drip irrigation.)<br />

• Electricity — We are continually seeking ways to reduce the usage of electricity for our<br />

food processing operations. We use electricity to convey products around our facilities,<br />

to control temperature and humidity of internal manufacturing areas, to provide internal<br />

and external lighting and to chill and freeze products.<br />

• Fuels — We utilize fuels (primarily natural gas and oil) to cook and sterilize products,<br />

as well as to provide heat in work areas. We are focused on reducing the amount of<br />

fuels used while maintaining high product quality and safety.<br />

• Waste to Landfill — Some waste materials generated in food production cannot be<br />

reused or recycled. These non-toxic wastes are disposed of in several ways, including<br />

landfill. A key strategy for our company is to reduce the amount of unavoidable waste<br />

that goes to landfills for disposal.<br />

Environmental Initiative<br />

<strong>Heinz</strong> North America<br />

Pocatello, Idaho, facility implemented an energy leak<br />

tagging system, whereby any leak points for compressed<br />

air or water are identified, a tag applied, and a work<br />

order generated to correct the leak. Air leaks have been<br />

reduced by 60 percent. This facility also installed flow<br />

meters and control valves to reduce the water used in<br />

cooling cooked pasta, reducing by 43 percent the amount<br />

of water needed for this process step.<br />

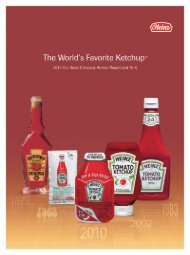

therms/pound Fuel used per pound of finished product<br />

0.030<br />

0.025<br />

0.020<br />

0.015<br />

0.010<br />

May 02<br />

May 03<br />

May 04<br />

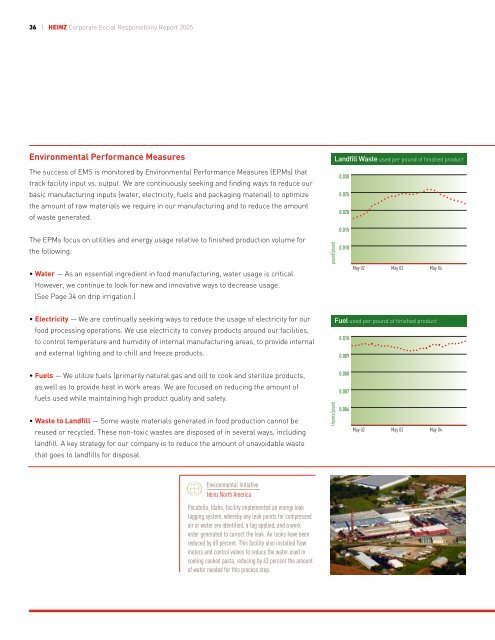

pound/pound Landfill Waste used per pound of finished product<br />

0.010<br />

0.009<br />

0.008<br />

0.007<br />

0.006<br />

0.005<br />

May 02<br />

May 03<br />

May 04