Wega 401 M2.40 FKW - EWM Hightec Welding GmbH

Wega 401 M2.40 FKW - EWM Hightec Welding GmbH

Wega 401 M2.40 FKW - EWM Hightec Welding GmbH

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

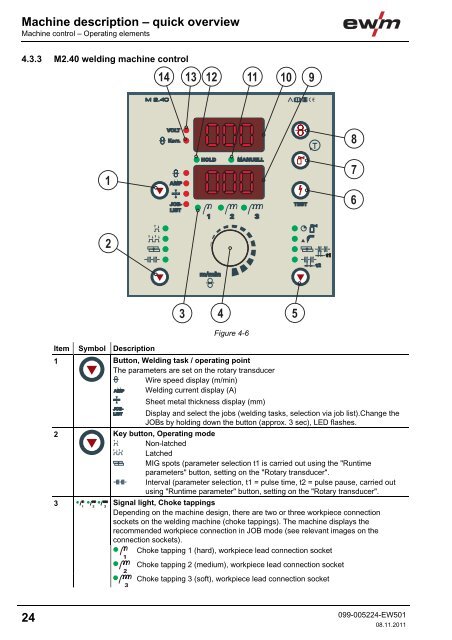

Machine description – quick overviewMachine control – Operating elements4.3.3 <strong>M2.40</strong> welding machine controlItem Symbol Description 0Figure 4-61 Button, <strong>Welding</strong> task / operating pointThe parameters are set on the rotary transducerWire speed display (m/min)<strong>Welding</strong> current display (A)Sheet metal thickness display (mm)Display and select the jobs (welding tasks, selection via job list).Change theJOBs by holding down the button (approx. 3 sec), LED flashes.2 Key button, Operating modeNon-latchedLatchedMIG spots (parameter selection t1 is carried out using the "Runtimeparameters" button, setting on the "Rotary transducer".Interval (parameter selection, t1 = pulse time, t2 = pulse pause, carried outusing "Runtime parameter" button, setting on the "Rotary transducer".3Signal light, Choke tappingsDepending on the machine design, there are two or three workpiece connectionsockets on the welding machine (choke tappings). The machine displays therecommended workpiece connection in JOB mode (see relevant images on theconnection sockets).Choke tapping 1 (hard), workpiece lead connection socketChoke tapping 2 (medium), workpiece lead connection socketChoke tapping 3 (soft), workpiece lead connection socket24099-005224-EW50108.11.2011