Wega 401 M2.40 FKW - EWM Hightec Welding GmbH

Wega 401 M2.40 FKW - EWM Hightec Welding GmbH

Wega 401 M2.40 FKW - EWM Hightec Welding GmbH

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

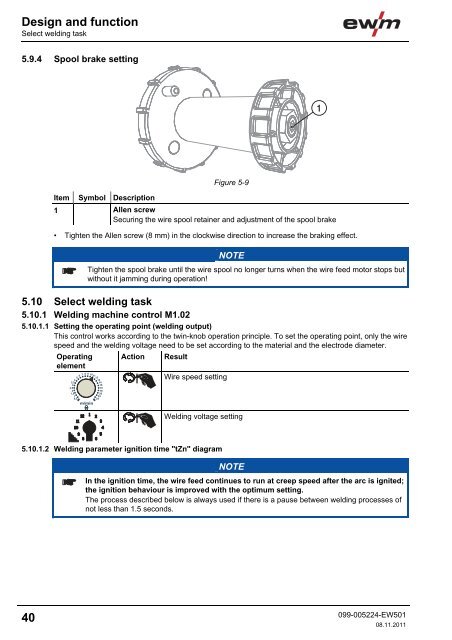

Design and functionSelect welding task5.9.4 Spool brake setting1Item Symbol Description 0Figure 5-91 Allen screwSecuring the wire spool retainer and adjustment of the spool brake• Tighten the Allen screw (8 mm) in the clockwise direction to increase the braking effect.NOTETighten the spool brake until the wire spool no longer turns when the wire feed motor stops butwithout it jamming during operation!5.10 Select welding task5.10.1 <strong>Welding</strong> machine control M1.025.10.1.1 Setting the operating point (welding output)This control works according to the twin-knob operation principle. To set the operating point, only the wirespeed and the welding voltage need to be set according to the material and the electrode diameter.OperatingelementActionResultWire speed setting<strong>Welding</strong> voltage setting5.10.1.2 <strong>Welding</strong> parameter ignition time "tZn" diagramNOTEIn the ignition time, the wire feed continues to run at creep speed after the arc is ignited;the ignition behaviour is improved with the optimum setting.The process described below is always used if there is a pause between welding processes ofnot less than 1.5 seconds.40099-005224-EW50108.11.2011