Induction Motors

Induction Motors

Induction Motors

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

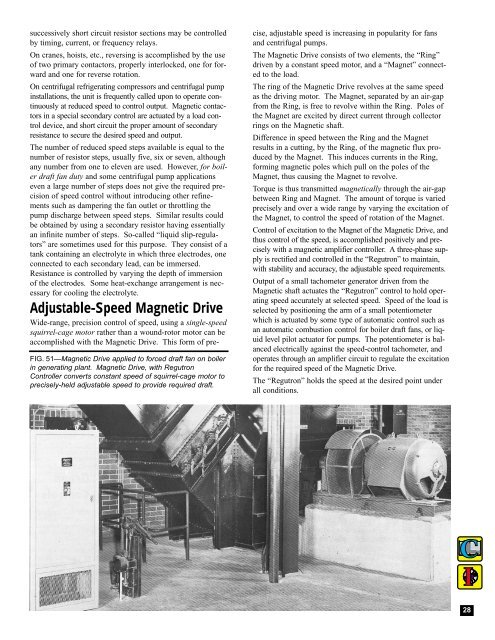

successively short circuit resistor sections may be controlledby timing, current, or frequency relays.On cranes, hoists, etc., reversing is accomplished by the useof two primary contactors, properly interlocked, one for forwardand one for reverse rotation.On centrifugal refrigerating compressors and centrifugal pumpinstallations, the unit is frequently called upon to operate continuouslyat reduced speed to control output. Magnetic contactorsin a special secondary control are actuated by a load controldevice, and short circuit the proper amount of secondaryresistance to secure the desired speed and output.FIG. 51—Magnetic Drive applied to forced draft fan on boilerin generating plant. Magnetic Drive, with RegutronController converts constant speed of squirrel-cage motor toprecisely-held adjustable speed to provide required draft.The number of reduced speed steps available is equal to thenumber of resistor steps, usually five, six or seven, althoughany number from one to eleven are used. However, for boilerdraft fan duty and some centrifugal pump applicationseven a large number of steps does not give the required precisionof speed control without introducing other refinementssuch as dampering the fan outlet or throttling thepump discharge between speed steps. Similar results couldbe obtained by using a secondary resistor having essentiallyan infinite number of steps. So-called “liquid slip-regulators”are sometimes used for this purpose. They consist of atank containing an electrolyte in which three electrodes, oneconnected to each secondary lead, can be immersed.Resistance is controlled by varying the depth of immersionof the electrodes. Some heat-exchange arrangement is necessaryfor cooling the electrolyte.Adjustable-Speed Magnetic DriveWide-range, precision control of speed, using a single-speedsquirrel-cage motor rather than a wound-rotor motor can beaccomplished with the Magnetic Drive. This form of precise,adjustable speed is increasing in popularity for fansand centrifugal pumps.The Magnetic Drive consists of two elements, the “Ring”driven by a constant speed motor, and a “Magnet” connectedto the load.The ring of the Magnetic Drive revolves at the same speedas the driving motor. The Magnet, separated by an air-gapfrom the Ring, is free to revolve within the Ring. Poles ofthe Magnet are excited by direct current through collectorrings on the Magnetic shaft.Difference in speed between the Ring and the Magnetresults in a cutting, by the Ring, of the magnetic flux producedby the Magnet. This induces currents in the Ring,forming magnetic poles which pull on the poles of theMagnet, thus causing the Magnet to revolve.Torque is thus transmitted magnetically through the air-gapbetween Ring and Magnet. The amount of torque is variedprecisely and over a wide range by varying the excitation ofthe Magnet, to control the speed of rotation of the Magnet.Control of excitation to the Magnet of the Magnetic Drive, andthus control of the speed, is accomplished positively and preciselywith a magnetic amplifier controller. A three-phase supplyis rectified and controlled in the “Regutron” to maintain,with stability and accuracy, the adjustable speed requirements.Output of a small tachometer generator driven from theMagnetic shaft actuates the “Regutron” control to hold operatingspeed accurately at selected speed. Speed of the load isselected by positioning the arm of a small potentiometerwhich is actuated by some type of automatic control such asan automatic combustion control for boiler draft fans, or liquidlevel pilot actuator for pumps. The potentiometer is balancedelectrically against the speed-control tachometer, andoperates through an amplifier circuit to regulate the excitationfor the required speed of the Magnetic Drive.The “Regutron” holds the speed at the desired point underall conditions.28