SITC OF LT Switch gear for Doordarshan, HPT Vizag - All India Radio

SITC OF LT Switch gear for Doordarshan, HPT Vizag - All India Radio

SITC OF LT Switch gear for Doordarshan, HPT Vizag - All India Radio

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SPEED POSTPRASAR BHARATI(Broadcasting Corporation of <strong>India</strong>)O/o THE ADDDITIONAL DIRECTOR GENERAL (E) (SOUTH ZONE)ALL INDIA RADIO & DOORDARSHANSwamy Sivananda Salai, Chennai - 600 005No.ADG(E)SZ/PUR-II/08/PSEA /2012-13 Date: 05-06-2012Sub.: Enquiry <strong>for</strong> <strong>SITC</strong> <strong>OF</strong> <strong>LT</strong> <strong>Switch</strong> <strong>gear</strong> <strong>for</strong> <strong>Doordarshan</strong>, <strong>HPT</strong>,Visakhapatnam.Dear Sir,1. DESCRIPTION:-SEALED TENDERS ARE HEREBY INVITED FOR AND ON BEHALF <strong>OF</strong> THEPRESIDENT <strong>OF</strong> INDIA, FROM REPUTED FIRMS FOR THE SUPPLY,INSTALLATION, TESTING AND COMMISSIONING <strong>OF</strong> <strong>LT</strong> <strong>Switch</strong> <strong>gear</strong> <strong>for</strong><strong>Doordarshan</strong>, <strong>HPT</strong>, VisakhapatnamConsignee: O/o The DDG(E) / Installation Officer, <strong>Doordarshan</strong>, <strong>HPT</strong>,Visakhapatnam.2. The quotation should specifically mention Make & Type of the items, deliverydate, terms and condition of supply. The prices given should be firm and as under.(a) The prices quoted shall remain fixed during the entire period ofsupply/contract and shall not be subject to variation on any account. A bidsubmitted with an adjustable price quotation is likely to be treated as nonresponsive and rejected.(b) The ‘Unit’ Price should be <strong>for</strong> the Unit as indicated in the tender enquiry.(c) Prices quoted should be <strong>for</strong> F.O.R. Station of destination in <strong>India</strong> andInclusive of charges as packing customs, etc., wherever applicable.(d) The quotation should specifically mention rates <strong>for</strong> Supply, Installationcharges & Taxes separately.3. In case of Quotation of F.O.R Station of dispatch basis, the purchaser will notpay separately transit insurance and the supplier will be responsible until thestores arrive in good condition at the destination. Tender/quotation in whichtransit insurance has been specified as an additional item of expenditure isliable to be ignored.4. The tender shall consists of three parts (bids) namely :(a) EMD: Earnest Money amounting to Rs.8,000/- [Rupees Eight thousands only]in the <strong>for</strong>m of Demand Draft on Nationalized Bank / Commercial Bank drawnin favour of The ADG (E) (SZ), AIR & DD, Chennai-5 should accompany thetender. Tenders without EMD shall be summarily rejected and their bid will notbe opened at the time of tender opening and shall be rejected as non responsiveat the bid opening stage and returned to the bidder unopened [EMD exemptionis applicable <strong>for</strong> those who are registered with the Central PurchaseOrganization, National Small Industries Corporation (NSIC) or the ConcernedMinistry or Department [ MIB / DG:AIR / DG:DD].1

(b) TECHNICAL BID: Technical bid should contain the confirmation to theenclosed technical specifications. This should be submitted in a separate sealedenvelope with “TECHNICAL BID” written on it.(c) COMMERCIAL BID:The commercial bid should contain the price bid andacceptance of the commercial terms and conditions of this tender document.The price should be quoted <strong>for</strong> free delivery of materials at respectivedestinations. This should be submitted in a separate sealed envelope with “Thetenders will be submitted in sealed envelopes with the name of work, date ofopening and the bid enclosed written on the envelopes.The above mentioned envelopes should be enclosed and submitted in anotherlarge size envelope duly sealed and superscribed with <strong>SITC</strong> <strong>OF</strong> <strong>LT</strong> <strong>Switch</strong> <strong>gear</strong><strong>for</strong> <strong>Doordarshan</strong>, <strong>HPT</strong>, Visakapatnam. “and date of opening. Theenvelope will be received at this office of The ADG(E) (SZ), AIR & TV, Swamy SivanandaSalai, Chennai-5 up to 1230 hrs. on 26.06.2012 . The technical bid and E.M.D. will beopened on the same day at 1500 hrs. The commercial bid will be notified afterrecommendation of technical committee.In case tender opening date falls on a holiday, the bids will be received andopened at the same specified time on next working day. Bids received late orsubmitted after the scheduled specified time on scheduled date will not beentertained and will be returned back unopened.The purchaser may, at his discretion extent the deadline <strong>for</strong> the submission ofthe bids by amending the bid document, in which case all rights andobligations of the purchaser and bidders previously subject to then deadline willthereafter be subject to the deadline as extended.Tenderer should quote <strong>for</strong> all the required items. Partial tenders will berejected.(d) SECURITY DEPOSIT: the successful Tenderer shall furnish the SecurityDeposit within 2 weeks after placement of order at the rate of 5% of the OrderValue, failing which the EMD will be <strong>for</strong>feited automatically, to Presidentof <strong>India</strong>, without any notice. The security deposit shall be furnished in the<strong>for</strong>m of Demand Draft / Bank Guarantee drawn in favour of The ADG (E) (SZ),AIR & DD, Chennai-5. The Security Deposit will be returned in full oncompletion of successful Guarantee/Warranty Period.5. TAXES:a. Payment o f Entry Ta x / O ctroi D ut y and Toll T ax (on ultimateproducts). As the material, which is to be transported to the consignee,belongs to the Government of <strong>India</strong> / Prasar Bharati and there<strong>for</strong>e isexempted from Entry Tax / Octroi Duty / T oll Tax. However, if the StateGovernments / Statutory Local Bodies are bound to levy such taxes, thetaxes will be paid by supplier / contractor. Supplier / Contractor may raiseits claim, <strong>for</strong> reimbursement of such duties / taxes paid, withOrganisation, along with original receipt of the payment.b. Sales Tax / Service Tax leviable and intended to be claimed from the purchasershould be distinctly shown along with prices quoted. Where this is not done noclaim <strong>for</strong> Sales Tax / Service Tax will be admitted at any later stage and on anyground whatsoever.* Please note that this Office will not issue any Form such as ‘C’, ‘D’ etc.6. Printed terms and conditions of tendering firms will not be considered as<strong>for</strong>ming parts of their tender.7. GUARANTEE / WARRANTY PERIOD: The Equipment / Work shall beguaranteed against any Manufacturing defects <strong>for</strong> a period of 1 Year from thedate of commissioning. Any parts failing during the Guarantee period shall berepaired / replaced free of charge by the supplier at the Sites.2

8. DELIVERY <strong>OF</strong> STORES: The <strong>SITC</strong> of <strong>LT</strong> <strong>Switch</strong><strong>gear</strong> at <strong>Doordarshan</strong>’s site shallbe completed within 3 Months from the date of placement of order. Deliveryperiod may also be quoted separately.9. TERMS <strong>OF</strong> PAYMENT:a. 80% of the contract price <strong>for</strong> the equipments/materials inclusive of ExciseDuty and Sales Tax shall be paid on initial inspection and delivery ofequipments at site in good condition.b. 20% of the contract price <strong>for</strong> the equipments/materials and 100% ofInstallation charges on satisfactory completion of Installation, Testing,Commissioning and Handing over.10. The quotation should be sent in a sealed cover addressed to the undersigned, byname, so as to reach on or be<strong>for</strong>e 26 .06.2012, 12.30 P.M.THE COVER SHOULD BE SUPERSCRIBED WITH THE FOLLOWING:a. Material <strong>for</strong> which quotations are enclosed.b. Reference to letter of enquiry.c. Due date of opening quotation.11. The Quotations will be opened in this office at 3.00 P.M. on 26.06.2012 in thepresence of tenderers or their agents such as they may choose to attend.12. QUOTATIONS NOT PROPERLY SUPERSCRIBED WILL NOT BECONSIDERED.13. The quotations submitted shall remain open <strong>for</strong> acceptance <strong>for</strong> a period of90 (Ninety) days from the date of opening of the Tender. If any Tenderer/Suppliers withdraws his Tender/Quotation be<strong>for</strong>e the said period or makesany modifications in the Terms & Conditions on the Tender/Quotationwhich are not acceptable to the Department, then the Government shall,without prejudice to any other right or remedy, be at the liberty to <strong>for</strong>feit50% of the Earnest Money as a<strong>for</strong>esaid.14. Both your PAN - Permanent Income Tax Account Number and Income TaxCircle & your TIN - Tax Identification Number and the Tax circle should bedefinitely indicated in your quotation.15. In case of supply of any Specific or Manufacturer item, the Manufacturer’s TestCertificate/preferably from MSME, should be enclosed with the supply. TheGoods are subjected to Inspection be<strong>for</strong>e acceptance. The date of Inspectionof may be intimated to this Office be<strong>for</strong>e dispatch to the consignee.16. RIGHT <strong>OF</strong> ACCEPTANCE: The undersigned reserves the right to reject thelowest tender or all the tenders without assigning any reasons whatsoever.Further, the undersigned reserves himself the right to increase or decrease upto 50% of the quantity of goods and services specified in the schedule of therequirement without any change in the unit price of the order quantities orother term conditions at the time of award of contract. <strong>All</strong> Quotations/Tendersin which any of the prescribed conditions are not fulfilled or are incomplete inany respect are liable to be rejected. The competent authority on behalf ofPresident of <strong>India</strong> reserve himself the right of accepting the whole or any part ofthe Tender shall be bound to per<strong>for</strong>m the same at the rate quoted.17. Canvassing whether directly or indirectly, in connection with Tender/quotationis strictly prohibited and the Tender/quotation submitted by the Contractors /suppliers who resort to canvassing will be liable to rejection.18. The undersigned also reserves the right to place Repeat Order up to 50% of thequantity of goods and services contain in the running tender / contract within aperiod of 6 months from the date of order/ agreement at the same rate.3

19. LANGUAGE / UNITS: <strong>All</strong> in<strong>for</strong>mation supplied by the Tenderer & all markings,notes, designation on the drawings & associated write-ups shall be in “Englishlanguage" only. <strong>All</strong> dimensions, units on drawings, all references to weights,measures & quantities shall be in MKS.20. In case this is second enquiry, your Quotation in response to the first enquiryshould be presumed to be valid up to 120 days from the last date mentioned inpara 11 above unless we hear from you.21. EXPERIENCE: The tenderer should give documentary proof <strong>for</strong> havingsuccessfully designed. Fabricated, installed and commissioned similar type ofequipment/work. They should also submit list of works which are in hand at thetime of submission of tender. The list shall contain the name of work, cost of workand present position of work.22. AFTER SALES SERVICE:- The Tenderer should give full details of after salesservice capability. The locations of service centers across the country shall beindicated. If there is no service centers at/ near the location of the site the tender islikely to be rejected.23. TECHNICAL SPECIFICATION AND GENERAL TERMS AND CONDITIONS:-For technical specification <strong>for</strong> other general terms and conditions see theAnnexures. The tenderer should submit necessary pamphlets description ofitems being offered along with technical bid and also the firms to whichsimilar items were supplied in the near past and completion report.24. FAILURE AND TERMINATION CLAUSETime and date of delivery shall be essence of the contract. If theContractor / Supplier fails to deliver the stores / execute <strong>SITC</strong> / SETC, orany installment thereof within the period fixed <strong>for</strong> such delivery in theschedule or at any time repudiates the contract be<strong>for</strong>e the expiry of suchperiods, the purchaser may without prejudice to any other right or remedy,available to him to recover demurrages <strong>for</strong> breach of the contract:-(a) Recover from the Supplier/Contractor as agreed, liquidated demurragesincluding Administrative expenses and not by way of penalty, a sumequivalent to 0.5% per week up to maximum limit of 10% of the contractvalue <strong>for</strong> such delay or part thereof (this is an agreed, genuine pre-estimateof demurrages duly agreed by the parties) which the supplier/contractor hasfailed to deliver thereof is accepted after expiry of the a<strong>for</strong>esaid period,provided that the total demurrages so claimed shall not exceed 10% of thecontract price of the stores / <strong>SITC</strong> / SETC. After full period of extension,termination of the contract will be considered by the Organization.(b) Purchase or authorize the purchase elsewhere on the account and at the riskof the contractor/supplier, of the stores not so delivered / <strong>SITC</strong> / SETC notcarried out or other of a similar description (where stores exactly complyingwith the particulars are not in the opinion of the purchaser, which shall befinal, readily procurable) by serving prior notice to the contractor/supplierwithout cancelling the contract in respect of the installment not yet due <strong>for</strong>delivery or,(c) Cancel the contract or a portion thereof by serving prior notice to theContractor/Supplier and if so desired purchase or authorize the purchase ofthe stores not so delivered / <strong>SITC</strong> / SETC not carried out, or others ofa similar description (where stores not delivered / <strong>SITC</strong> / SETC not carriedout, exactly complying with particulars are not in the opinion of thepurchaser, which shall be final readily procurable) at the risk and cost of theContractor/Supplier. If the Contractor/Supplier had defaulted in theper<strong>for</strong>mance of the original contract, the purchaser shall have the right toignore his tender <strong>for</strong> risk purchase even though the lowest, where the contractis terminated at the risk and cost of the firm under the provisions of thisclause, it shall be in the discretion of the purchaser to exercise hisdiscretion to collect or not, the Security deposit from the firm on whom thecontract is placed, at the risk and expense of the defaulted firm.4

(d) Where action is taken under sub-clause (b) or sub-clause (c) above,the contractor shall be liable <strong>for</strong> any loss which the purchaser may sustainon that account, provided the purchase or if there is an agreement, topurchase, such agreement is made in case of failure to deliver theS tores/Services, within 6 months from the date of such failure and in caseof repudiation of contract the Contractor/Supplier shall not be entitled toany gain on such the entire discretion of the purchaser to serve a notice ofsuch purchase on the Contractor/Supplier.(e) It may further be noted that clause (a) above provides <strong>for</strong> recovery ofliquidated demurrages on the cost of contract price of delayed supplies(whole unit) at the rate of 0.5% per week up to maximum limit of 10% of thecontract value <strong>for</strong> such delay or part thereof. Liquidated demurrages <strong>for</strong>delay in supplies thus accrued will be recovered by the paying authority oninstruction as specified in the supply order, from the bill <strong>for</strong> payment of thecost of materials / works submitted by the supplier / contractor inaccordance with terms of supply order on instruction from Purchaserregarding liquidated demurrages amount.(f) Notwithstanding anything stated above, equipment and materials will bedeemed to have been delivered / <strong>SITC</strong> / SETC will be deemed to have beencarried out only when all its components, parts are also delivered. If certaincomponents of stores are not delivered in time / <strong>SITC</strong> / SETC not carried outin time, the stores / <strong>SITC</strong> / SETC will be considered as delayed until suchtime all the missing parts are also delivered.25. ARBITRATION <strong>OF</strong> CONTRACTUAL DISPUTES:If a dispute arises out of or in connection with the contract, or in respect of anydefined legal relationship associated therewith or derived there from, the partiesagree to submit that dispute to arbitration under ICADR Arbitration Rules,1996.The Authority to appoint the arbitrator(s) shall be the International Centre<strong>for</strong> Alternative dispute resolution.The International centre <strong>for</strong> Alternative Dispute Resolution will provideadministrative services in accordance with the ICADR Arbitration Rules, 1996.a) The number of arbitrator(s) shall be one who has legal as well asTechnical Background.b) The language of the arbitration proceedings shall be English.c) The place of arbitration proceedings shall be Chennai only.26. GENERAL:- <strong>All</strong> the pages of the tender document should be duly signed,stamped and serially numbered on submission, failing which the tender maynot be considered as qualified tenderWeb Site: http://ceszairdd.org.in/Tenders.phphttp://www.allindiaradio.org/tender.htmlhttps://tenders.gov.inEncl:- 1. Annexure-I page 6-192. Annexure-II page 20-21(M.Sujatha)ASSISTANT ENGINEER<strong>for</strong> ADG (E) (SZ)Tele: 044 -2538 2155Tele-fax: 044 – 2538 2583e-mail:adgszpurchase@gmail.com5

ANNEXURE-ITECHNICAL SPECIFICATIONS FOR MAIN <strong>LT</strong> PANEL ATVISHKHAPATTAMGENERAL :1.1.1 <strong>All</strong> switchboards shall comply with the requirements of IS8623 applicable <strong>for</strong> Factory Built Assemblies (FBA).1.1.2 Refer to attached drawings & schedules <strong>for</strong> ratings ofindividual components and equipment.1.1.3 The FBA shall consist of vertical sections, joined togetherto <strong>for</strong>m a rigid, free standing, completely enclosed assembly.1.1.4 The FBA shall have adequate strength to withstand allstress imposed by shipping, handling, installation andoperation, without distortion or damages.1.1.5 The switch<strong>gear</strong>s shall be fabricated using suitable mild steelstructural sections or pressed and shaped cold rolledsheet steel of thickness of 2 mm <strong>for</strong> load bearing members,1.6 mm <strong>for</strong> non-load bearing members and 3 mm <strong>for</strong> basechannel. The base frame shall be integral to theswitchboard and shall be suitable <strong>for</strong> tack welding to thepurchaser’s floor embedded channels.1.1.6 FBA shall be of single/double front construction asindicated in the drawings.1.1.7 The FBA shall be as completely assembled as possiblewithin shipping and handling limitations, wired and ready<strong>for</strong> installation in accordance with this specification1.1.8 The switchboards shall be of folded sheet steel construction,fully compartmentalized, floor mounted, free standingtype and dust, damp & vermin proof. The degrees ofprotection shall be as IP 54 as per IS 2147 standards.Vertical units shall be assembled to <strong>for</strong>m a continuous lineup of uni<strong>for</strong>m height and front line up.1.1.9 Door openings shall be provided with neoprene gaskets. <strong>All</strong>hardware shall be corrosion resistant. <strong>All</strong> joints andconnections of the panel members shall be made bycadmium plated high quality steel bolts, nuts & washers,secured against loosening using spring washers, whereveressential. Star washers shall be used to ensure effectivecontinuity.1.1.10 <strong>All</strong> doors shall be hinged at one end and shall be bolted(knob type) on the other end. <strong>All</strong> hinges shall be ofconcealed design <strong>for</strong> elegant appearance1.1.11 Adequate lifting facilities shall be provided on each section.Lifting eyes may be <strong>for</strong> removable/foldable design. Whenremoved these shall not leave any opening on the boards. <strong>All</strong>barriers used shall be manufactured from fire retardantnon-inflammable and non-hygroscopic materials, such asFBRR/FR-2 only. HYLAM IS NOT ACCEPTABLEThe switch<strong>gear</strong> shall be easily extendable on both sides bythe addition of vertical sections after removing the endcovers.Compliance6

GENERAL :1.1.12 The switch<strong>gear</strong> shall be provided with indelibly markedmetallic labels on the front and rear indicating theswitch<strong>gear</strong> designation.1.1.13 The equipment shall be designed to ensure complete safetyduring operation, inspection & connection of cables,relocation of out going circuits and maintenance, even withthe bus bar system energized. Features which preventshorting of power and/or control terminals due to accidentaldropping of maintenance tools, etc., inside the switchboardshall be provided. <strong>All</strong> auxiliary equipment/components shallbe easily accessible.1.1.14 <strong>All</strong> exposed live terminals in the cable alley and incomerterminals inside modules shall be covered or shrouded toprevent accident contact.The incoming power connection to the switchboard shall bethrough bus trunking or cables as specified in the drawing.Ample space <strong>for</strong> connection of these cables/bus trunkingshall be provided.1.1.15 The switch<strong>gear</strong> shall be provided with gaskets all around theperimeter of covers, gland plates, removable covers anddoors.1.1.16 Operating devices shall be located only in the front side ofthe switch<strong>gear</strong>. No equipment shall be located below 250mm and above 1900 mm.1.1.17 The bottom/top (as specified) of each panel shall be fittedwith removable sheet steel plates <strong>for</strong> use as a gland plate <strong>for</strong>cable entry.1.1.18 <strong>All</strong> modules shall have cable termination facility in cablealley without duplicated terminals and it should be possibleto terminate/disconnect cables without removing themodules.1.1.19 The switchboards shall be divided into distinct verticalsections each comprising :a) A completely metal enclosed bus bar compartmentrunning horizontally.b) Individual feeder modules arranged in multi-tier<strong>for</strong>mation.c) Enclosed vertical bus bars serving all modules in thevertical sections.d) A vertical cable alley covering the entire height.e) Horizontal wires way <strong>for</strong> inter panel control wiring.f) Separate auxiliary bus bar chamber runningthroughout the length of the switchboard.1.1.20 Metal sheets shall be provided between the adjacent verticalsections <strong>for</strong> running to the full height of the switch <strong>gear</strong>except <strong>for</strong> the horizontal bus bar compartment.Compliance7

GENERAL :1.1.21 In the main <strong>LT</strong> panels, withdraw able chassis shall beprovided with a plate cover on the side corresponding to thecable alley of the compartment. The front of thecompartments shall be provided with a door. The rear of thecompartment shall be covered by a metal or insulated sheetwith slots to permit connections to the bus bars. <strong>All</strong> othercovers shall be of sheet steel.1.1.22 Suitable barriers shall be provided between circuit breakersand all control, protective and indication circuit equipment.External cable connection shall be carried out in a separatecable compartment.1.1.23 Rear of single front switch<strong>gear</strong> shall be provided withremovable covers. The covers shall be fixed in position bycaptive screws.1.2 VERTICAL SECTIONS :1.2.1. The vertical sections shall be front accessible and shall bedivided into functional units <strong>for</strong> housing motor feeders,distribution feeders & other power control units.1.2.2 The vertical sections shall be provided with an independent,fully enclosed horizontal wire way. It shall be readilyaccessible by removal of cover plates and shall <strong>for</strong>m aconvenient wiring space and to house auxiliary bus barsrunning throughout the length of the switch<strong>gear</strong>.1.2.3 Each panel shall contain an isolated, full height cablechamber of at least 250 mm width <strong>for</strong> the Main <strong>LT</strong> Panel,covered by a hinged door.1.3 BUSBARS :1.3.1 Power shall be distributed by main bus bars of uni<strong>for</strong>mcross section, provided across the switch<strong>gear</strong>, with verticalbus bars (droppers) extending into each section to supplypower to each individual function unit in the Main <strong>LT</strong> Panel.The supply of neutral shall be through a neutral bus bar andstab-in-contact in all the units wherever required. Externallooping through a separate contact is not permitted.1.3.2 Bus bars shall be high conductivity copper (E 91 E grade)supported on insulators made of non-hygroscopic, noninflammablematerial with tracking index equal to or morethan 600 as per IEC 112. Hylam Sheet is not acceptable.Horizontal busbars shall be of uni<strong>for</strong>m cross sectionthroughout the length of the switchboards and upto theincoming terminals of the incoming feeder circuitbreaker/switch. Vertical busbars of all vertical panels of theswitchboard shall be of uni<strong>for</strong>m cross section. The neutralof the bus system shall be at least half the size of that of thephase bus bars. <strong>All</strong> bus bars shall be insulated with heatshrunk PVC sleeves of 1100 V grade red, yellow and bluecolour shall be used <strong>for</strong> phase bus bars and black colourshall be used <strong>for</strong> neutral bus bars. If the insulating sleeveis not coloured, bus bars shall be colour coded with bands atsuitable intervals. Joints shall be shrouded suitably.Stepped bus bars shall not be acceptable. Interconnectionsbetween the main bus bars and individual units shall bemade by using vertical aluminum bus bars of adequaterating. These interconnections and the vertical bus barsCompliance8

shall be compartmentalized and fully shrouded. Vertical busbars <strong>for</strong> circuit breaker panels shall be sized dependingupon the rating and number of breakers per vertical panel.Vertical bus bars <strong>for</strong> <strong>LT</strong> panels shall be of uni<strong>for</strong>m crosssection. Size of vertical bus bars <strong>for</strong> <strong>LT</strong> panels should beincorporated suitable to the load (copper bus bar) as per thedrawing enclosed. e. <strong>All</strong> joint surfaces at aluminum tocopper joints shall be silver/tin plated alternatively cup-alwashers (bimetallic washers) may be used.1.3.3 The main and vertical bus bars (droppers) shall be a TPNsystem. The main and vertical bus bars shall be housed inseparate, fully enclosed chambers to prevent direct contactwith the buses being energized when FBA is underoperation. <strong>All</strong> phase and neutral bars shall be housed in acommon chamber.The bus bars, droppers and incoming links shall further beinsulated by heat shrunk PVC sleeves to provide additionalprotection against accidental contact and to preventfailure in the presence of <strong>for</strong>eign matter. The sleeves usedshall be capable of withstanding the temperatures attainedby bus bars during normal operation & short circuits. Useof paint as insulation <strong>for</strong> bus bars is not acceptable.1.3.4 Bus bars shall be supported on arc resistant, flameretardant supports moulded from thermosetting glass,rein<strong>for</strong>ced plastic having high insulation resistance, highrigidity at elevated temperatures and very high trackingresistance. Comparative tracking index value <strong>for</strong> thematerial shall be at least 1000 V as per IS 2824 .The supportdesign shall be such that creepage distance between phasesshall be higher than those specified in IS 4237. Necessaryanti tracking barriers shall be built-in in the design of thesupport. The clearance shall be at least 35 mm betweenphases and phase to earth in the main bus bar zone and 28mm in vertical bus bar (droppers) zone.1.3.5 Both TPN horizontal and vertical bus bars, bus joints andsupports shall be capable of withstanding dynamic andthermal stresses of the specified short circuit currents <strong>for</strong> 1sec only. Zinc passivated or cadmium plated high tensilestrength steel bolts, nuts and washers shall be used <strong>for</strong> alljoints and supports. The short circuit capacity of theneutral bus bars shall be in line with IS:13497. Thesupplier should have standard design <strong>for</strong> 50 KVA <strong>for</strong> 1 secfaults withstand capability and should offer this optionwhenever specified.1.3.6 Provision of control supply in the test position of draw outmodules (feeders, which require control, supply) shall beavailable. In draw out switchboards with module controlsupply, required test control supply feeder, associated testsupply bus/wiring, etc., shall be provided.1.3.7 No wiring shall be to the door. Only the actuators of thepush buttons and switches, lenses <strong>for</strong> the indicating lampsas per specs. Cover <strong>for</strong> meters shall be mounted on thedoor.9

1.4 WIRING : Compliance1.4.1 The switch<strong>gear</strong> shall be supplied completely wired internallyupto terminal blocks <strong>for</strong> the purchaser’s external cableconnections at the terminal blocks. Inter panel wiringbetween cubicles of the same switch<strong>gear</strong> shall be routedinside by the vendor.1.4.2 <strong>All</strong> auxiliary wiring shall be carried out with 650 V grade,single core stranded copper conductor with PVC insulation.The sizes of wire shall not be less than 2.5 sqmm per head ofCT circuits and 1.5 sqmm per lead of other circuits. Thewire shall con<strong>for</strong>m to IS 1554.1.4.3 Each control wire shall be identified at both ends with wiredesignation in accordance with the relevant <strong>India</strong>nStandards. <strong>All</strong> wire terminals shall be with compression orclamp type connectors. <strong>All</strong> power & control wiringterminations shall be done through lugs. Ring type lugs isto be used <strong>for</strong> power connections.1.4.4 Power & control wires shall be neatly bunched separatelyand adequately supported so as to prevent sagging.1.4.5 Not more than two wires shall be connected to one terminalblock.1.5 CABLE TERMINATIONS :1.5.1 The Main <strong>LT</strong> Panel shall be designed to facilitate cable entryfrom the top/bottom. Removable gland plates of 2 mm thicksheet steel or 3 mm thick aluminum gland plates shall befurnished <strong>for</strong> cable entry, which will be drilled at the site tofit in the cable glands.1.5.2 Sufficient space shall be provided to avoid sharp bendingand the construction shall facilitate easy connection.1.5.3 Multi-way terminal blocks complete with screws, nut,washers, shall be furnished <strong>for</strong> terminating the control andpower cables.1.5.4 Power terminals <strong>for</strong> cables shall be complete with ring typecrimping lugs. Screw type terminals with screw directlyimpinging on the conductor are not acceptable.1.5.5 For incoming feeders where the aluminum power cable sizesare expected to be large the cable, termination arrangementshall be clearly defined. Where such large cable sizes cannotbe terminated directly on standard outgoing power terminalsor equipment terminals, a suitable cabling bus shall beprovided <strong>for</strong> adequate and proper termination of cables. Theclearances & creepage distances in such a section shall bethe same as those in the busbar zones of the standardsection.1.5.6 Shorting links shall be provided <strong>for</strong> CT terminals to facilitatetesting.1.5.7 Bolted type terminals with crimping type lugs shall beprovided <strong>for</strong> all cable connections greater than 10 sqmm.2 SWITCH BOARD COMPONENTS :2.1 ON LOAD CHANGE OVER SWITCH : 1 No2.1.1 Con<strong>for</strong>ming to specification IS : 13947 – IS2.1.2 It shall have contacts made from electrolytic copper and aresilver-plated.2.1.3 The body material shall be having excellent thermalmechanical and electrical properties.10

2.1.4 It shall have robust level <strong>gear</strong> mechanism <strong>for</strong> smooth changeover.2.1.5 Mechanical position indicator shall be provided on the frontof the change over switch to give an indication of the statusof the contact made.2.1.6 Test certificates from competent authorities shall beobtained and produced at the time of inspection.2.1.7 The change over switch shall be of reputed make such asL&T, English Electric Control <strong>Switch</strong><strong>gear</strong>, SchneiderElectricals, Crompton Greaves, etc.,2.2 MOULDED CASE CIRCUIT BREAKERS : Compliance2.2.1 No. of poles - 4Rated Voltage- 415 volts(AC 50 Hz)Rated Insulated Voltage - 800 VoltRated impulse withstand voltage - 8 KV2.2.2 The moulded case circuit breaker shall be of reputed makesuch as L&T, English Electric Control <strong>Switch</strong><strong>gear</strong>, SchneiderElectricals, Crompton Greaves, etc.,2.3 CURRENT TRANSFORMER :2.3.1 Current trans<strong>for</strong>mers (CTs) shall con<strong>for</strong>m to IS 2705. CTsshall be of cast2.3.2 Resin insulated type. Primarily suitable CTs should be used.2.3.3 CTs shall shall have a short time withstand rating equal tothe short time withstand rating of the associated switch<strong>gear</strong><strong>for</strong> 1 sec. <strong>for</strong> breaker feeder. For other feeders withfuses/MCCB CTs shall have withstand capacity equal to letthrough current.2.3.4 Separate CTs shall be used <strong>for</strong> metering and protection.2.3.5 CTs shall be provided with polarity markings adjacent toterminals both <strong>for</strong> primary and secondary.2.4 INSTRUMENTS AND METERS : multifunction meter shouldbe provided.2.5 INDICATING LAMPS:2.5.1 Indicating lamps shall be of LED type as called <strong>for</strong> in thisspecifications.2.5.2 <strong>All</strong> indicating lamps shall be clear type with appropriatecoloured lenses ensuring clarity of colour.2.5.3 Necessary protective fuses shall be provided <strong>for</strong> the lampcircuit in the breaker feeders.2.6 CABLE GLANDS:Double compression nickel-plated brass cable glandssuitable <strong>for</strong> all outgoing/incoming power and control cables,as per sizes indicated in section II.2.7 NAME PLATES:a. <strong>All</strong> nameplates shall be of anodized aluminum withblack background and white engraved type letters,which shall be fixed with screws :b. Letter size – 6 mmc. Nameplates <strong>for</strong> individual feeders shall indicate feederno., description, rating in KW/Ad. Panel nos. are to be provided on both front and rearsidese. Main nameplate of board with letter 25mm shall beprovided at the end of the board in bold letters.Besides, manufacturer’s name, address, board no.etc., shall be provided11

f. Designation <strong>for</strong> all components, viz., switches, fuses,relays, etc., mounted in the cubicle shall also be done.2.8 EARTHING : Compliance2.8.1 A continuous earth bus as specified in the data sheet shallbe provided <strong>for</strong> the entire length of the switchboard. Aminimum of two terminals shall be provided on the bus <strong>for</strong>external connection to earth grid.2.8.2 <strong>All</strong> panels shall be effectively bounded to a switch<strong>gear</strong> earthbus of galvanized steel. Positive earthing shall also bemaintained in all positions of chassis and breaker frame.2.8.3 <strong>All</strong> non-current carrying metallic parts of the equipmentshall be earthed.2.8.4 <strong>All</strong> hinged doors and covers shall be provided with suitableflexible earthing connections.2.8.5 The size of the earth bus chosen shall be to withstand fullfault current.2.8.6 Earth bus bars shall be supported at suitable intervals.2.8.7 <strong>All</strong> withdraw able chassis shall be earthed through springloaded silver plated copper scrapping earth contact whichmake-be<strong>for</strong>e & break-after the power contacts areengaged/disengaged. A suitable vertical earth bus shall beprovided <strong>for</strong> each front of the panel <strong>for</strong> this purpose.2.9 PAINTING :2.9.1 <strong>All</strong> metal surfaces shall be thoroughly cleaned and degreasedto remove mill scale, rust, grease, dirt, etc.,Fabricated structure shall be picked and then rinsed toremove any trace of acid. The under surface shall beprepared by applying a coat of phosphate paint and coat ofyellow zinc chromate primer. The under surface shall bemade free from all imperfections be<strong>for</strong>e undertaking thefinishing coat.2.9.2 The phosphate coating shall be sealed by the application oftwo coats of ready mixed zinc chromate primer.2.9.3 After application of the primer, two coats of finishingsynthetic enamel paint shall be applied or shall be powdercoated epoxy based (second coat to be applied aftercompletion of tests).2.9.4 The finished panels shall be dried in staving ovens in dustfree atmosphere. Panels finish shall be free fromimperfections like pinholes, orange peels, runoff paint, etc.,2.9.5 <strong>All</strong> unpainted steel parts shall be cadmium plated orsuitable treated to prevent rust <strong>for</strong>mation. If these parts aremoving elements, then they shall be greased.2.9.6 A small quantity of finishing paint shall be supplied <strong>for</strong>minor touch up required at the site after the installation ofthe switch<strong>gear</strong>.2.9.7 Whenever called <strong>for</strong> in particular projects, the completedswitchboards shall be painted with peel-able paint.2.9.8 Vendor shall furnish detailed painting procedure proposedalong with the bid.2.10 PACKING :2.10.1 The switchboard shall be shipped to site packed in fullwooden packing cases. They shall be wrapped inpolyethylene sheets be<strong>for</strong>e being placed in cases to preventdamages to the finish. Cases shall have skid bottoms <strong>for</strong>handling.12

2.10.2 The board shall be properly packed be<strong>for</strong>e dispatch to avoiddamage during transport, storage and handling to all siteanywhere in <strong>India</strong>.2.10.3 The packing box shall contain a copy of the installation,operation and maintenance manual.2.10.4 A sign to indicate the upright position of the panels to beplaced during transport and storage shall be clearly marked.Also proper arrangements shall be provided to handle theequipment.2.11 TESTS & INSPECTIONS : Compliance2.11.1 <strong>Switch</strong><strong>gear</strong> shall be subject to routine tests as per IS 86232.11.2 <strong>All</strong> meters and other reference devices used <strong>for</strong> testing shallhave valid calibration from reputed nationallaboratories/institutes. Inspection by purchases will not becarried out unless the vendor confirms that equipment areready <strong>for</strong> proceeding with the tests.2.11.3 Shop test shall be witnessed by our inspector or owner or anagency authorized by us.2.11.3 Acceptance tests on completed switchboards shall be asfollows :a) A general visual check shall be carried out. Thisshall cover measurement of overall dimension,location, number and type of devices, terminalboxed, location and connection of terminals, etc.,b) Checking of bill of materials as per approveddrawingc) Checking of operation of various feeders as perapproved schematic drawingsd) Operation check shall be carried out <strong>for</strong> everycontrol function as per schematic drawings bymanually simulating fault conditions and operationof control switches/relay, etc.e) Checking of interchangeability of identical feeders.f) Insulation resistance test and value measurementon power and control circuits be<strong>for</strong>e and after highvoltage withstand testg) For equipment bought from other suppliers, certifiedtest reports of test carried out at the manufacturer’sworks shall be submitted.h) Functional check of all Instruments / Indicators.i) Calibration of protective relays <strong>for</strong> circuit currentvalue.2.12 DOCUMENTATION :Following documents shall be submitted along withthe bid :a) General arrangement and foundation details ofthe Main <strong>LT</strong> Panelb) Bus bar sizing calculation <strong>for</strong> various bus barrating of the Main <strong>LT</strong> Panelc) Quality assurance plan <strong>for</strong> the switchboards.2.13 DRAWINGS & INSTRUCTIONS MANUALS :2.13.1 <strong>All</strong> drawings submitted by the vendor shall be in sufficientdetail to indicate the type size, arrangement, weight,breakdown <strong>for</strong> packing and shipment, the externalconnections, fixing arrangements required, the dimensionsrequired <strong>for</strong> installation and interconnections with other13

equipment and materials, clearances and spaces requiredbetween various portions of equipment and any otherin<strong>for</strong>mation specifically requested. Bolted joints shall be asper DIN standard bolting schedule. Visual indicator shall beprovided to inspect tightness of all bus bar/dropper boltedjoints. <strong>All</strong> drawout tap-offs on Main <strong>LT</strong> Panel droppers shallbe properly designed silver plated contacts. A contact platearrangement <strong>for</strong> dropper tap-off to avoid wear & tear offdroppers is essential.2.13.2 Appropriate coloured bands shall be provided on main busbars and vertical bus bars <strong>for</strong> providing phase identificationin line with requirement of IS-375.2.13.3 Provision shall exist in a separate chamber <strong>for</strong> mountingadequate insulated auxiliary bus bars,, supported onmoulded supports <strong>for</strong> control/interlocking/ annunciationpurposes as required. The wiring shall be directly tappedfrom auxiliary bus bars to the withdrawable units. Unit tounit looping shall not be permitted. The material of controlpower supply buses shall be electrolytic copper. Thematerial <strong>for</strong> space heater power supply buses shall be sameas that <strong>for</strong> the main power buses.2.13.4 The clearance and creepage distances shall not be lowerthan the values specified below :a) Minimum clearance between two live conductors –20 mmb) Minimum clearance between live part & accidentallydangerous part– 20mmc) Minimum creepage distance – 28 mm2.13.5 Unless specified otherwise in particular project, temperaturerise bus bars when carrying rated current shall be limited to35 deg C above ambient temperature of 50 deg C.2.13.6 Location of bus bars shall be at the top <strong>for</strong> panels withbottom cable entry and at the bottom <strong>for</strong> panels with topcable entry.2.13.7 Bus bar material shall be either copper or aluminum as perspecifications.2.13.8 Room dimensions are provided in the drawing <strong>for</strong> reference.2.14 TOOLS AND APPLIANCES Compliance2.14.1 The vendor shall supply without any extra cost one set ofspecial tools and appliances that may be required <strong>for</strong>carrying out the maintenance, special inspection, etc., of theequipment offered.2.14.2 Vendor shall also furnish list tools and appliances required<strong>for</strong> different equipment.2.15 GUARANTEE:Equipment shall be guaranteed <strong>for</strong> a period of 12 monthsfrom the date of commissioning.14

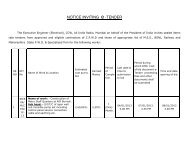

SCHEDULE <strong>OF</strong> REQUIREMENT <strong>OF</strong> <strong>LT</strong> PANEL(Bill Of Material)Details of MCCB/ACB/Meters :1. The MCCBs, and Changeover switch should be ofSchneider, L&T, Havel’s, Siemens,LEGRAND2. The indicating meters should be of AE, MECO Make.S.No. DETAILS <strong>OF</strong> THE ITEM RATING QTY REMARKS RATE1 MCB 200 A, 415 V100 A, 415 V63 A, 415 V32 A, 415 V1 No2 Nos4 Nos5 Nos4 pole MCB2 MCCB 32 A, 415 V20 A, 415 V16 A, 415 V5 A, 415 V4 Nos12 Nos12 Nos12 Nos3 Change over switch, MCCB 100 A, 415 V 1 No 4 pole4 BUSBAR : 200 Acopper bus bar 1 set5 METERS :i. Multifunction meter 2 nosii. Phase sequence indicator 415 V 1 no6. INDICATORS :i. Red, yellow and blue 1 set LED type7. PROTECTIVE DEVICES :i Earth fault relay with core1 no PROK DVsbalance trans<strong>for</strong>merii Overvoltage/undervoltage1notripping device.8 Earth Leakage relay 1 set9 Insurance, Transportation &unloading at site of theabove switch<strong>gear</strong>1 Job15

10 a) Installations includingconsumable hardware, interconnecting control cablingwith cables, input & outputsupply cable terminationwith lugs to and fro from <strong>LT</strong>Panel and extension of earthfrom client’s earth bus etc.b) Testing & commissioningof the above <strong>LT</strong> <strong>Switch</strong><strong>gear</strong>c) Complete installationmaterial <strong>for</strong> the above switch<strong>gear</strong>.NB: <strong>LT</strong> Cable <strong>for</strong> input &output shall be supplied by<strong>Doordarshan</strong>11 Special tools if any required<strong>for</strong> field maintenance andrepair of ACBs & MCCBs(List of tools to be enclosed)12 Book of instructions <strong>for</strong>Installation, operations,Testing, Commissioning andMaintenance includingfinalized drawings1 Job1Job1 Lot1 Set4 SetsNOTE :- <strong>All</strong> applicable taxes should be quoted separately.16

ANNEXURE-IIGENERAL TERMS AND CONDITIONS FOR WORK ORDER1) NAME <strong>OF</strong> PURCHASER : The President of <strong>India</strong>2) PAYING AUTHORITY : The ADG(E)(SZ), AIR & DDSwamy Sivananda Salai, CHENNAI-6000053) PAYMENT TERMSa. 80% of the contract price <strong>for</strong> the equipments/materials inclusive of Excise Dutyand Sales Tax shall be paid on initial inspection and delivery of equipments at sitein good condition.b. 20% of the contract price <strong>for</strong> the equipments/materials and 100% of Installationchargeson satisfactory completion of Installation, Testing, Commissioning andHanding over.4) BILLS :<strong>All</strong> the supplies and works shall be in con<strong>for</strong>mity with the order and all the part billsshall be prepared in quadruplicate in the same <strong>for</strong>mat as that of the Work Order. <strong>All</strong>those part bills shall be submitted to the consignee <strong>for</strong> necessary certificates andonward transmission to the paying authority.5) DESPATCH INSTRUCTIONS:The packing and marking of goods shall be as laid down in clause-12 ofgeneral conditions of contract DGS & D69 (revised).6) The contractor shall arrange to dispatch the goods duly insured direct to theconsignee under prior intimation <strong>for</strong> delivery at site by whichever mode of transporthe may choose, to ensure safe delivery of goods at site. Unloading shall be done atsite at the contractor’s expense. The consignee will provide only storage space. Thecontractor will provide his own security like locking etc., and store the materials athis own risk.7) INSPECTION :The material will be inspected at site. If any damages are found, material will berejected.8) INSURANCE:The contractor shall arrange <strong>for</strong> the insurance covering the risk during transit,storage and installation till commissioning. <strong>All</strong> the charges <strong>for</strong> such insurance shallbe borne by the contractor.9) ADDITIONAL QUANTITIES:The purchaser reserves the right to place order <strong>for</strong> additional quantity up to 100% ofthe ordered quantity at the same rates and terms and condition during the currencyof the contract.10) PENA<strong>LT</strong>Y FOR DELAYIf the contractor is unable to complete the supply, installation, testing andcommissioning within the stipulated time limit the purchaser may at his option allowsuch additional time as may be considered justified with/without penalty andwithout altering terms and conditions of the order. In the event of failure of thecontractor to complete the supply, installation testing and commissioning within thestipulated time or the extended time, the purchaser has the right to impose penalty of0.5% per week or part thereof the contract price. The Contractor’s liability <strong>for</strong> delay,however, shall not exceed 10% of the total contract price.11) GUARANTEE/ WARRANTY:The contractor shall accept clause-18 of the Form no. DGS & D-71 with exceptionthat his obligation shall be limited <strong>for</strong> a period of 12 months from the date of takingover completion of the successful per<strong>for</strong>mance excluding down time during which theequipment was not working satisfactorily due to defective parts, faulty material/design/workmanship or faulty erection. During the guarantee period the contractorshall repair or replace free of charge any parts that will become defective due to faultymaterial design, workmanship or erection.20

12) CONDITIONS <strong>OF</strong> CONTRACT:a. DGS & D-68 (Revised) and DGS & D-71 as amended up to date. However, suchof these conditions stipulated on this tender shall supercede correspondingconditions in DGS & D-71.b. The contractor shall sign a contract agreement <strong>for</strong>m in triplicate in theprescribed pro<strong>for</strong>ma and submit the same along with Security Deposit within 2weeks. The complete <strong>for</strong>m with the purchaser’s signature shall be sent back to thecontractor. No supplies will be made and no work shall start unless the agreementis signed by the contractor and the purchaser.13) ENFORCEMENT <strong>OF</strong> LABOUR LAWS:While engaging labour <strong>for</strong> carrying out obligations under the contract the contractorshall satisfy the conditions laid down under contract labour (Regulation andAudition) Act 1970 and (Central) Rules 1971 as amended from time to time andobserve all <strong>for</strong>malities required as per the said Act/ Rules. The supplier shall alsoobserve the provision under minimum wages act 1948(Central) Rules 1950 amendedfrom time to time while engaging labour.14) ARBITRATION <strong>OF</strong> CONTRACTUAL DISPUTES:If a dispute arises out of or in connection with the contract, or in respect of anydefined legal relationship associated therewith or derived there from, the partiesagree to submit that dispute to arbitration under ICADR Arbitration Rules, 1996.The Authority to appoint the arbitrator(s) shall be the International Centre <strong>for</strong>Alternative dispute resolution.The International Center <strong>for</strong> Alternative Dispute Resolution will provideadministrative services in accordance with the ICADR Arbitration Rules, 1996.The number of arbitrator(s) shall be one who has legal as well as technicalbackground.d) The language of the arbitration proceedings shall be English.e) The place of arbitration proceedings shall be Chennai.15) FORCE MAJEURE:a. If any time during the continuance of the contract the per<strong>for</strong>mance in whileor in part by the contractor shall be prevented or delayed by reason of any war,hostility acts of the public enemy. Civil commotion, sabotage, fires, floods,explosions, epidemics, Quarantine restrictions, strikes, lock-outs or acts of God(therein after restrictions refer to as events and provided notice of happenings of anysuch eventuality is given by the contractor within 21 days from the date ofoccurrence thereof, the purchaser shall by reason of such event, neither be entitledto cancel this order not shall have any claim <strong>for</strong> damages against the contractor inrespect of such non-per<strong>for</strong>mance or delay in per<strong>for</strong>mance and delivery shall beresumed as soon as practicable after such events have come to an end or ceased toexist.b. Provided further that if the per<strong>for</strong>mance in whole or part or any obligationunder this order is prevented or delayed by reasons of any such event <strong>for</strong> a periodexceeding 180 days, the purchaser and the contractor shall meet to find a neutralagreement to any effect resulting the re<strong>for</strong>m or the purchaser may at his optioncancel order provided also if the order is cancelled under this clause, the purchasershall be at liberty to take over from the contractor at order prices all unused, undamagedand acceptable material bought out components and stores in course ofmanufacture in the possession of the supplier at the time of such cancellation orsuch portion thereof as the purchaser may deem fit accepting such material, boughtout components and stores as the supplier may with the concurrence of thepurchaser elect to retain.16) CANCELLATION:The purchaser reserves the right to cancel the order in the event of nonper<strong>for</strong>mance/ delay in execution of the work or unsatisfactory per<strong>for</strong>mance by thecontractor and recover payment already made if any, along with losses/ damagesincurred.(M.Sujatha)ASSISTANT ENGINEER<strong>for</strong> ADG (E) (SZ)21