Confined Spaces - Workplace Safety and Health Council

Confined Spaces - Workplace Safety and Health Council

Confined Spaces - Workplace Safety and Health Council

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

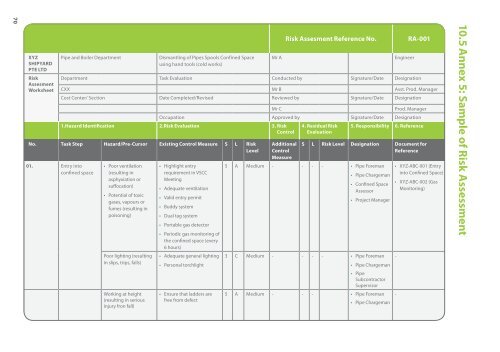

Risk Assesment Reference No. RA-001XYZSHIPYARDPTE LTDRiskAssesmentWorksheetPipe <strong>and</strong> Boiler Department Dismantling of Pipes Spools <strong>Confined</strong> Spaceusing h<strong>and</strong> tools (cold works)Mr A EngineerDepartment Task Evaluation Conducted by Signature/Date DesignationCXX Mr B Asst. Prod. ManagerCost Center/ Section Date Completed/Revised Reviewed by Signature/Date DesignationMr C Risk Assesment Reference No. Prod. ManagerRA-001Occupation Approved by Signature/Date Designation1.Hazard Identification 2.Risk Evaluation 3. Risk 4. Residual Risk 5. Responsibility 6. ReferenceMr Control A EvaluationEngineerNo. Task Step Hazard/Pre-Cursor Existing Control Measure S L RiskLevel01. Entry intoconfined spaceAdditionalControlMeasure• Potential of toxic1.Hazard Identification•gases, vapours or 2.RiskValidEvaluationentry permit3. Riskfumes (resulting in • Buddy systemControlpoisoning)No. Task Step Hazard/Pre-Cursor•ExistingDual tagControlsystemMeasure S L RiskS L Risk Level Designation Document forReferenceCXX Mr B Asst. Prod. Manager• Poor ventilation • Highlight entry5 A Medium - - - - • Pipe Foreman • XYZ-ABC-001 (EntryCost Center/ Section (resulting inDate requirement Completed/Revised in VSCCReviewed by Signature/Date Designation• Pipe Chargemaninto <strong>Confined</strong> Space)asphyxiation orMeetingMr Csuffocation)• <strong>Confined</strong> Space Prod. • XYZ-ABC-002 Manager (Gas• Adequate ventilationAssessorMonitoring)Occupation Approved by Signature/Date Designation5. • Responsibility Project Manager 6. Reference• Portable gas detector02. Visual inspection,identification<strong>and</strong> marking ofpipe spools (ofpipeline) to bedismantled.03. Dismantlingof identifiedpipe spoolsby loosening<strong>and</strong> removingfasteners in wayof flanged pipeconnections,using h<strong>and</strong> tools.03. DismantlingH<strong>and</strong>of identifiedtoolsincludepipe spoolsspanners,hammerby looseningorchisel.<strong>and</strong> removingfasteners in wayof flanged pipeconnections,using h<strong>and</strong> tools.Poor lighting (resultingin slips, trips, falls)Working at height(resulting in seriousinjury fron fall)• Awkward posture(resulting inergonomic injuries)• Slippery / Wetsurfaces (resulting inslips/ trips/ falls)• Potential of beingstruck by objectduring inspectionSlippery/wet process (resulting surfaces in(resulting laceration in or slips/ bruise)trips/falls)• Ignition of residuals/ combustibles(resulting in fire <strong>and</strong>Potential explosion) of beingstruck by object duringinspection process(resulting in lacerationor bruise)• Potential of toxicgases, vapours orfumes (resulting inpoisoning)• Slippery / Wetsurfaces (resulting inslips/ trips/ falls)Potential of toxic gases,vapours or fumes(resulting in poisoning)•PeriodicHighlightgasentrymonitoring oftherequirementconfined spacein VSCC(every6Meetinghours)Adequate general lighting• Adequate ventilationPersonal torchlight• Valid entry permit• Buddy system• Dual tag system• Ensure Portable that gas ladders detector arefree from defect• Ensure Adequate that general unguarded lightinglightening holes/ opening•sPersonalare coveredtorchlight• Adopt 3-pt contact whenusing ladder•AdequateEnsure thatlightingladdersonareaccessfree fromwaysdefect• Slow <strong>and</strong> careful• movements Ensure that unguardedwhile makinginspectionlightening holes/openings• Observeare coveredproper body• posture Adopt 3-point contact• Ensurewhen usingadequateladderworking• space Adequate / platform lighting onaccess ways5 A Medium - - - - • Pipe Foreman• Pipe Chargeman3 C Medium - - - - • <strong>Confined</strong> Pipe Foreman SpaceAssessor• Pipe Chargeman• Project ManagerPipeSubcontractorSupervisor5 A Medium - - - • Pipe Foreman• Pipe Chargeman• Pipe• Pipe Subcontractor Chargemansupervisor• PipeSubcontractor2 B Low - - - - • SupervisorPipe Foreman• Pipe Chargeman• PipeSubcontractorsupervisor• Slow <strong>and</strong> carefulClean up slippery / wet movements while makingresidual near pipelineinspectionidentified2 C Medium - - - - • Pipe Foreman• Pipe Chargeman•AdequateObserve properworkingbodylights2 B Low - - - - • Pipe ForemanpostureSubcontractor• PPE (safety shoes)• PipesupervisorChargeman• Ensure adequate working• Proper space/platform PPE (safety helmet) • Pipe2 C Medium - - - - Pipe ForemanSubcontractor• SupervisorPipe Chargeman• Clean up slippery/wet 2 C Medium - - - - • Pipe Foremanresidual near pipelineSubcontractor• PipesupervisorChargemanidentified• Pipe• Highlight Adequate specific working lights 5 A Medium - - - - Pipe Forem<strong>and</strong>ismantling requirementsSubcontractor• • Pipe ChargemaninPPEVSCC(safetymeetingshoes)Supervisor• Proper Valid PPE ‘dismantling (safety helmet) of pipes’ Ship Engineer /2 C Medium - - - - • Pipe ForemanOfficerpermit• Pipe Chargeman• Lockout-tagout (LOTO) toisolate system.• Prominent display of• appropriate Highlight specific signboardsat dismantling all entrances requirementsto theconfined VSCC meeting space• Use Valid of “dismantling adequate flame ofproof pipes” lights permit with cables ingood condition• Lockout-tagout (LOTO) to• No isolate ‘hot-work’ system. in theconfined space• Prominent display of• Adequate appropriate ventilation signboards• Portable at all entrances gas detector to theconfined space• Immediate evacuation of• Use of adequate flamethe confined space upondetection of toxic gasproof lights with cables in(briefing good condition to workers)• Use of containers/ plasticbags for collecting systemdischarge on opening•flangeAdequateconnections.ventilation•St<strong>and</strong>-byPortable gasoil spilldetectorcontrol• equipment Immediate evacuation (rags, saw of• Pipe• Pipe SubcontractorSubcontractorsupervisorSupervisor• Pipeworker5 A Medium - - - - • Pipe Foreman• Pipe Chargeman5 A Medium - - - - • PipeworkerForeman• Pipe Chargeman• PipeSubcontractorsupervisor• Pipeworker2 C Medium - - - - • Pipe Foreman• Pipe Chargeman5 A Medium - - - - • Pipe Foreman• Pipe Subcontractor Chargemansupervisor• Pipe• XYZ-ABC-003 (Permitto work System)• XYZ-ABC-004(Dismantling/Testing of Oil, Gas,Chemical & SteamPipelines/ Valves &Heating Coils)---10.5 Annex 5: Sample of Risk AssessmentXYZSHIPYARDPTE LTDRiskAssesmentWorksheetPipe <strong>and</strong> Boiler Department Dismantling of Pipes Spools <strong>Confined</strong> Space usingh<strong>and</strong> tools (cold works)Department Task Evaluation Conducted by Signature/Date DesignationLevel4. Residual RiskEvaluationS L Risk Level Designation Document forReference01. Entry intoconfined space02. Visualinspection,identification<strong>and</strong> marking ofpipe spools (ofpipeline) to bedismantled.(H<strong>and</strong> toolsincludespanners,hammer orchisel.)• Poor ventilation(resulting inAsphyxiation orSuffocation)• Potential of toxicgases, vapours orfumes (resulting inpoisoning)• Poor lighting(resulting to slips,trips, falls)• Working at height(resulting in seriousinjury fron fall)Awkward posture(resulting in ergonomicinjuries)Ignition of residuals/combustibles (resultingin fire <strong>and</strong> explosion)• Periodic gas monitoring ofthe confined space (every6 hours)• No “hotwork” in theconfined space3 C Medium - - - - • Pipe Foreman• PipeSubcontractorsupervisor5 A Medium - - - • Pipe Foreman• Pipe Chargeman• Ship Engineer/Officer• PipeSubcontractorSupervisor• XYZ-ABC-001 (Entryinto <strong>Confined</strong> Space)• XYZ-ABC-002 (GasMonitoring)• XYZ-ABC-003(Permit to WorkSystem)• XYZ-ABC-004(Dismantling/testingof oil, gas, chemical& steam pipelines/valves & heatingcoils)---70 71