Confined Spaces - Workplace Safety and Health Council

Confined Spaces - Workplace Safety and Health Council

Confined Spaces - Workplace Safety and Health Council

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

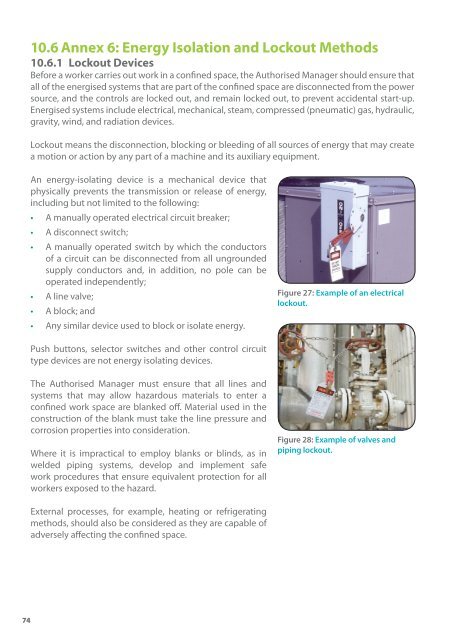

10.6 Annex 6: Energy Isolation <strong>and</strong> Lockout Methods10.6.1 Lockout DevicesBefore a worker carries out work in a confined space, the Authorised Manager should ensure thatall of the energised systems that are part of the confined space are disconnected from the powersource, <strong>and</strong> the controls are locked out, <strong>and</strong> remain locked out, to prevent accidental start-up.Energised systems include electrical, mechanical, steam, compressed (pneumatic) gas, hydraulic,gravity, wind, <strong>and</strong> radiation devices.Lockout means the disconnection, blocking or bleeding of all sources of energy that may createa motion or action by any part of a machine <strong>and</strong> its auxiliary equipment.10.6.2 Methods of Isolation from ContaminantsA confined space should be isolated before entry is permitted. The method of isolation shouldbe in accordance with one of the following methods or by an alternative method ensuringequivalent security:• Remove the spool piece or expansion joint in piping that leads to entrance of the confinedspace <strong>and</strong> then blank or cap its open end. The blank or cap should be identified to indicate itspurpose. Blanks or caps should be of a material that is compatible with the liquid, vapour or gaswith which they are in contact. The material should also have sufficient strength to withst<strong>and</strong>the maximum operating pressure, including surges, which can build up in the piping.An energy-isolating device is a mechanical device thatphysically prevents the transmission or release of energy,including but not limited to the following:• A manually operated electrical circuit breaker;• A disconnect switch;• A manually operated switch by which the conductorsof a circuit can be disconnected from all ungroundedsupply conductors <strong>and</strong>, in addition, no pole can beoperated independently;• A line valve;• A block; <strong>and</strong>• Any similar device used to block or isolate energy.Push buttons, selector switches <strong>and</strong> other control circuittype devices are not energy isolating devices.The Authorised Manager must ensure that all lines <strong>and</strong>systems that may allow hazardous materials to enter aconfined work space are blanked off. Material used in theconstruction of the blank must take the line pressure <strong>and</strong>corrosion properties into consideration.Where it is impractical to employ blanks or blinds, as inwelded piping systems, develop <strong>and</strong> implement safework procedures that ensure equivalent protection for allworkers exposed to the hazard.External processes, for example, heating or refrigeratingmethods, should also be considered as they are capable ofadversely affecting the confined space.Figure 27: Example of an electricallockout.Figure 28: Example of valves <strong>and</strong>piping lockout.Remove the expansion jointSpade (Blank)Blank the piping’s open endFigure 29: Example of isolation by discounting/removing a spool piece or expansion joint from piping systems.• Insertion of a suitable full-pressure spade (blank) in piping between the flanges near theconfined space. The full-pressure spade (blank) should be identified to indicate its purpose.Figure 30: Example of isolation by inserting a spade (blank) in piping between the flanges.74 75