DAY 1 - AMMJ

DAY 1 - AMMJ

DAY 1 - AMMJ

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

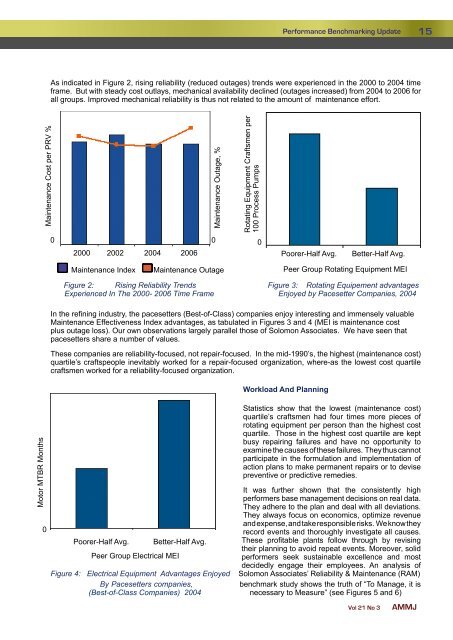

Performance Benchmarking Update15As indicated in Figure 2, rising reliability (reduced outages) trends were experienced in the 2000 to 2004 timeframe. But with steady cost outlays, mechanical availability declined (outages increased) from 2004 to 2006 forall groups. Improved mechanical reliability is thus not related to the amount of maintenance effort.Maintenance Cost per PRV %Maintenance Outage, %Rotating Equipment Craftsmen per100 Process Pumps02000 2002 2004 200600Poorer-Half Avg.Better-Half Avg.Maintenance IndexMaintenance OutagePeer Group Rotating Equipment MEIFigure 2: Rising Reliability Trends Figure 3: Rotating Equipement advantagesExperienced In The 2000- 2006 Time Frame Enjoyed by Pacesetter Companies, 2004In the refining industry, the pacesetters (Best-of-Class) companies enjoy interesting and immensely valuableMaintenance Effectiveness Index advantages, as tabulated in Figures 3 and 4 (MEI is maintenance costplus outage loss). Our own observations largely parallel those of Solomon Associates. We have seen thatpacesetters share a number of values.These companies are reliability-focused, not repair-focused. In the mid-1990’s, the highest (maintenance cost)quartile’s craftspeople inevitably worked for a repair-focused organization, where-as the lowest cost quartilecraftsmen worked for a reliability-focused organization.Workload And PlanningMotor MTBR Months0Statistics show that the lowest (maintenance cost)quartile’s craftsmen had four times more pieces ofrotating equipment per person than the highest costquartile. Those in the highest cost quartile are keptbusy repairing failures and have no opportunity toexamine the causes of these failures. They thus cannotparticipate in the formulation and implementation ofaction plans to make permanent repairs or to devisepreventive or predictive remedies.It was further shown that the consistently highperformers base management decisions on real data.They adhere to the plan and deal with all deviations.They always focus on economics, optimize revenueand expense, and take responsible risks. We know theyrecord events and thoroughly investigate all causes.Poorer-Half Avg. Better-Half Avg. These profitable plants follow through by revisingtheir planning to avoid repeat events. Moreover, solidPeer Group Electrical MEIperformers seek sustainable excellence and mostdecidedly engage their employees. An analysis ofFigure 4: Electrical Equipment Advantages Enjoyed Solomon Associates’ Reliability & Maintenance (RAM)By Pacesetters companies,benchmark study shows the truth of “To Manage, it is(Best-of-Class Companies) 2004 necessary to Measure” (see Figures 5 and 6)Vol 21 No 3<strong>AMMJ</strong>