DAY 1 - AMMJ

DAY 1 - AMMJ

DAY 1 - AMMJ

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

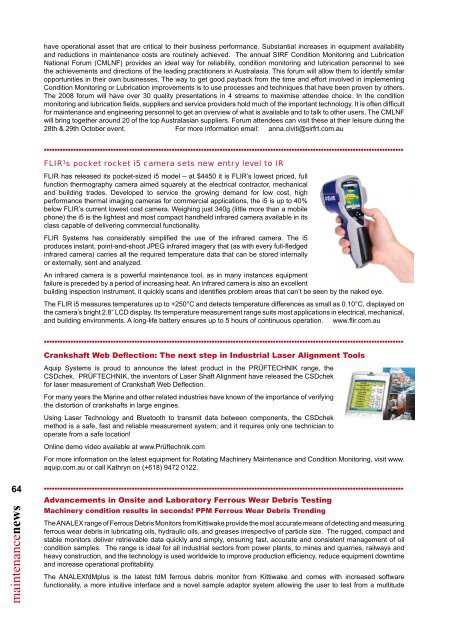

have operational asset that are critical to their business performance. Substantial increases in equipment availabilityand reductions in maintenance costs are routinely achieved. The annual SIRF Condition Monitoring and LubricationNational Forum (CMLNF) provides an ideal way for reliability, condition monitoring and lubrication personnel to seethe achievements and directions of the leading practitioners in Australasia. This forum will allow them to identify similaropportunities in their own businesses. The way to get good payback from the time and effort involved in implementingCondition Monitoring or Lubrication improvements is to use processes and techniques that have been proven by others.The 2008 forum will have over 30 quality presentations in 4 streams to maximise attendee choice. In the conditionmonitoring and lubrication fields, suppliers and service providers hold much of the important technology. It is often difficultfor maintenance and engineering personnel to get an overview of what is available and to talk to other users. The CMLNFwill bring together around 20 of the top Australasian suppliers. Forum attendees can visit these at their leisure during the28th & 29th October event. For more information email: anna.civiti@sirfrt.com.au•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••FLIR¹s pocket rocket i5 camera sets new entry level to IRFLIR has released its pocket-sized i5 model – at $4450 it is FLIR’s lowest priced, fullfunction thermography camera aimed squarely at the electrical contractor, mechanicaland building trades. Developed to service the growing demand for low cost, highperformance thermal imaging cameras for commercial applications, the i5 is up to 40%below FLIR’s current lowest cost camera. Weighing just 340g (little more than a mobilephone) the i5 is the lightest and most compact handheld infrared camera available in itsclass capable of delivering commercial functionality.FLIR Systems has considerably simplified the use of the infrared camera. The i5produces instant, point-and-shoot JPEG infrared imagery that (as with every full-fledgedinfrared camera) carries all the required temperature data that can be stored internallyor externally, sent and analyzed.An infrared camera is a powerful maintenance tool, as in many instances equipmentfailure is preceded by a period of increasing heat. An infrared camera is also an excellentbuilding inspection instrument, it quickly scans and identifies problem areas that can’t be seen by the naked eye.The FLIR i5 measures temperatures up to +250°C and detects temperature differences as small as 0.10°C, displayed onthe camera’s bright 2.8” LCD display. Its temperature measurement range suits most applications in electrical, mechanical,and building environments. A long-life battery ensures up to 5 hours of continuous operation. www.flir.com.au•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••Crankshaft Web Deflection: The next step in Industrial Laser Alignment ToolsAquip Systems is proud to announce the latest product in the PRÜFTECHNIK range, theCSDchek. PRÜFTECHNIK, the inventors of Laser Shaft Alignment have released the CSDchekfor laser measurement of Crankshaft Web Deflection.For many years the Marine and other related industries have known of the importance of verifyingthe distortion of crankshafts in large engines.Using Laser Technology and Bluetooth to transmit data between components, the CSDchekmethod is a safe, fast and reliable measurement system; and it requires only one technician tooperate from a safe location!Online demo video available at www.Prüftechnik.comFor more information on the latest equipment for Rotating Machinery Maintenance and Condition Monitoring, visit www.aquip.com.au or call Kathryn on (+618) 9472 0122.64maintenancenews•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••Advancements in Onsite and Laboratory Ferrous Wear Debris TestingMachinery condition results in seconds! PPM Ferrous Wear Debris TrendingThe ANALEX range of Ferrous Debris Monitors from Kittiwake provide the most accurate means of detecting and measuringferrous wear debris in lubricating oils, hydraulic oils, and greases irrespective of particle size. The rugged, compact andstable monitors deliver retrievable data quickly and simply, ensuring fast, accurate and consistent management of oilcondition samples. The range is ideal for all industrial sectors from power plants, to mines and quarries, railways andheavy construction, and the technology is used worldwide to improve production efficiency, reduce equipment downtimeand increase operational profitability.The ANALEXfdMplus is the latest fdM ferrous debris monitor from Kittiwake and comes with increased softwarefunctionality, a more intuitive interface and a novel sample adaptor system allowing the user to test from a multitude