DAY 1 - AMMJ

DAY 1 - AMMJ

DAY 1 - AMMJ

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

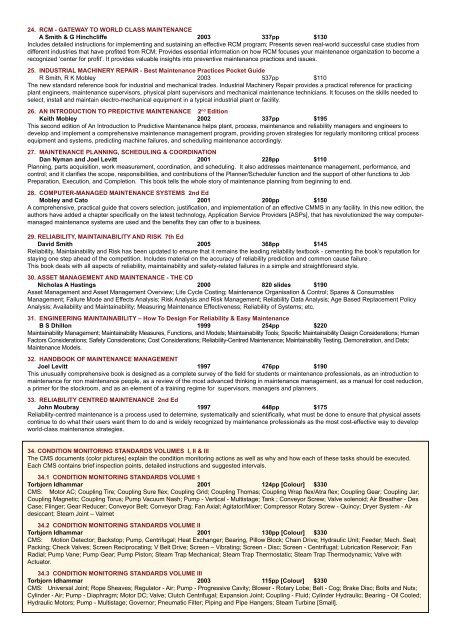

24. RCM - GATEWAY TO WORLD CLASS MAINTENANCEA Smith & G Hinchcliffe 2003 337pp $130Includes detailed instructions for implementing and sustaining an effective RCM program; Presents seven real-world successful case studies fromdifferent industries that have profited from RCM; Provides essential information on how RCM focuses your maintenance organization to become arecognized ‘center for profit’. It provides valuable insights into preventive maintenance practices and issues.25. INDUSTRIAL MACHINERY REPAIR - Best Maintenance Practices Pocket GuideR Smith, R K Mobley 2003 537pp $110The new standard reference book for industrial and mechanical trades. Industrial Machinery Repair provides a practical reference for practicingplant engineers, maintenance supervisors, physical plant supervisors and mechanical maintenance technicians. It focuses on the skills needed toselect, install and maintain electro-mechanical equipment in a typical industrial plant or facility.26. AN INTRODUCTION TO PREDICTIVE MAINTENANCE 2 nd EditionKeith Mobley 2002 337pp $195This second edition of An Introduction to Predictive Maintenance helps plant, process, maintenance and reliability managers and engineers todevelop and implement a comprehensive maintenance management program, providing proven strategies for regularly monitoring critical processequipment and systems, predicting machine failures, and scheduling maintenance accordingly.27. MAINTENANCE PLANNING, SCHEDULING & COORDINATIONDan Nyman and Joel Levitt 2001 228pp $110Planning, parts acquisition, work measurement, coordination, and scheduling. It also addresses maintenance management, performance, andcontrol; and it clarifies the scope, responsibilities, and contributions of the Planner/Scheduler function and the support of other functions to JobPreparation, Execution, and Completion. This book tells the whole story of maintenance planning from beginning to end.28. COMPUTER-MANAGED MAINTENANCE SYSTEMS 2nd EdMobley and Cato 2001 200pp $150A comprehensive, practical guide that covers selection, justification, and implementation of an effective CMMS in any facility. In this new edition, theauthors have added a chapter specifically on the latest technology, Application Service Providers [ASPs], that has revolutionized the way computermanagedmaintenance systems are used and the benefits they can offer to a business.29. RELIABILITY, MAINTAINABILITY AND RISK 7th EdDavid Smith 2005 368pp $145Reliability, Maintainability and Risk has been updated to ensure that it remains the leading reliability textbook - cementing the book’s reputation forstaying one step ahead of the competition. Includes material on the accuracy of reliability prediction and common cause failure .This book deals with all aspects of reliability, maintainability and safety-related failures in a simple and straightforward style.30. ASSET MANAGEMENT AND MAINTENANCE - THE CDNicholas A Hastings 2000 820 slides $190Asset Management and Asset Management Overview; Life Cycle Costing; Maintenance Organisation & Control; Spares & ConsumablesManagement; Failure Mode and Effects Analysis; Risk Analysis and Risk Management; Reliability Data Analysis; Age Based Replacement PolicyAnalysis; Availability and Maintainability; Measuring Maintenance Effectiveness; Reliability of Systems; etc.31. ENGINEERING MAINTAINABILITY – How To Design For Reliability & Easy MaintenanceB S Dhillon 1999 254pp $220Maintainability Management; Maintainability Measures, Functions, and Models; Maintainability Tools; Specific Maintainability Design Considerations; HumanFactors Considerations; Safety Considerations; Cost Considerations; Reliability-Centred Maintenance; Maintainability Testing, Demonstration, and Data;Maintenance Models.32. HANDBOOK OF MAINTENANCE MANAGEMENTJoel Levitt 1997 476pp $190This unusually comprehensive book is designed as a complete survey of the field for students or maintenance professionals, as an introduction tomaintenance for non maintenance people, as a review of the most advanced thinking in maintenance management, as a manual for cost reduction,a primer for the stockroom, and as an element of a training regime for supervisors, managers and planners.33. RELIABILITY CENTRED MAINTENANCE 2nd EdJohn Moubray 1997 448pp $175Reliability-centred maintenance is a process used to determine, systematically and scientifically, what must be done to ensure that physical assetscontinue to do what their users want them to do and is widely recognized by maintenance professionals as the most cost-effective way to developworld-class maintenance strategies.34. CONDITION MONITORING STANDARDS VOLUMES I, II & IIIThe CMS documents (color pictures) explain the condition monitoring actions as well as why and how each of these tasks should be executed.Each CMS contains brief inspection points, detailed instructions and suggested intervals.34.1 CONDITION MONITORING STANDARDS VOLUME 1Torbjorn Idhammar 2001 124pp [Colour] $330CMS: Motor AC; Coupling Tire; Coupling Sure flex; Coupling Grid; Coupling Thomas; Coupling Wrap flex/Atra flex; Coupling Gear; Coupling Jar;Coupling Magnetic; Coupling Torus; Pump Vacuum Nash; Pump - Vertical - Multistage; Tank ; Conveyor Screw; Valve solenoid; Air Breather - DesCase; Flinger; Gear Reducer; Conveyor Belt; Conveyor Drag; Fan Axial; Agitator/Mixer; Compressor Rotary Screw - Quincy; Dryer System - Airdesiccant; Steam Joint – Valmet34.2 CONDITION MONITORING STANDARDS VOLUME IITorbjorn Idhammar 2001 130pp [Colour] $330CMS: Motion Detector; Backstop; Pump, Centrifugal; Heat Exchanger; Bearing, Pillow Block; Chain Drive; Hydraulic Unit; Feeder; Mech. Seal;Packing; Check Valves; Screen Reciprocating; V Belt Drive; Screen – Vibrating; Screen - Disc; Screen - Centrifugal; Lubrication Reservoir; FanRadial; Pump Vane; Pump Gear; Pump Piston; Steam Trap Mechanical; Steam Trap Thermostatic; Steam Trap Thermodynamic; Valve withActuator.34.3 CONDITION MONITORING STANDARDS VOLUME IIITorbjorn Idhammar 2003 115pp [Colour] $330CMS: Universal Joint; Rope Sheaves; Regulator - Air; Pump - Progressive Cavity; Blower - Rotary Lobe; Belt - Cog; Brake Disc; Bolts and Nuts;Cylinder - Air; Pump - Diaphragm; Motor DC; Valve; Clutch Centrifugal; Expansion Joint; Coupling - Fluid; Cylinder Hydraulic; Bearing - Oil Cooled;Hydraulic Motors; Pump - Multistage; Governor; Pneumatic Filter; Piping and Pipe Hangers; Steam Turbine [Small].