DAY 1 - AMMJ

DAY 1 - AMMJ

DAY 1 - AMMJ

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

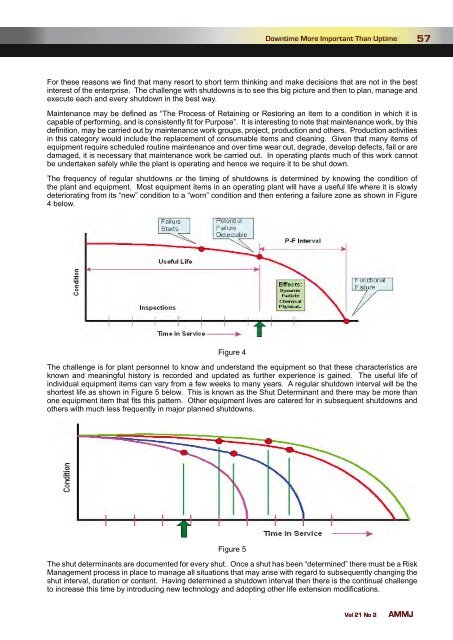

Downtime More Important Than Uptime57For these reasons we find that many resort to short term thinking and make decisions that are not in the bestinterest of the enterprise. The challenge with shutdowns is to see this big picture and then to plan, manage andexecute each and every shutdown in the best way.Maintenance may be defined as “The Process of Retaining or Restoring an item to a condition in which it iscapable of performing, and is consistently fit for Purpose”. It is interesting to note that maintenance work, by thisdefinition, may be carried out by maintenance work groups, project, production and others. Production activitiesin this category would include the replacement of consumable items and cleaning. Given that many items ofequipment require scheduled routine maintenance and over time wear out, degrade, develop defects, fail or aredamaged, it is necessary that maintenance work be carried out. In operating plants much of this work cannotbe undertaken safely while the plant is operating and hence we require it to be shut down.The frequency of regular shutdowns or the timing of shutdowns is determined by knowing the condition ofthe plant and equipment. Most equipment items in an operating plant will have a useful life where it is slowlydeteriorating from its “new” condition to a “worn” condition and then entering a failure zone as shown in Figure4 below.Figure 4The challenge is for plant personnel to know and understand the equipment so that these characteristics areknown and meaningful history is recorded and updated as further experience is gained. The useful life ofindividual equipment items can vary from a few weeks to many years. A regular shutdown interval will be theshortest life as shown in Figure 5 below. This is known as the Shut Determinant and there may be more thanone equipment item that fits this pattern. Other equipment lives are catered for in subsequent shutdowns andothers with much less frequently in major planned shutdowns.Figure 5The shut determinants are documented for every shut. Once a shut has been “determined” there must be a RiskManagement process in place to manage all situations that may arise with regard to subsequently changing theshut interval, duration or content. Having determined a shutdown interval then there is the continual challengeto increase this time by introducing new technology and adopting other life extension modifications.Vol 21 No 23<strong>AMMJ</strong>