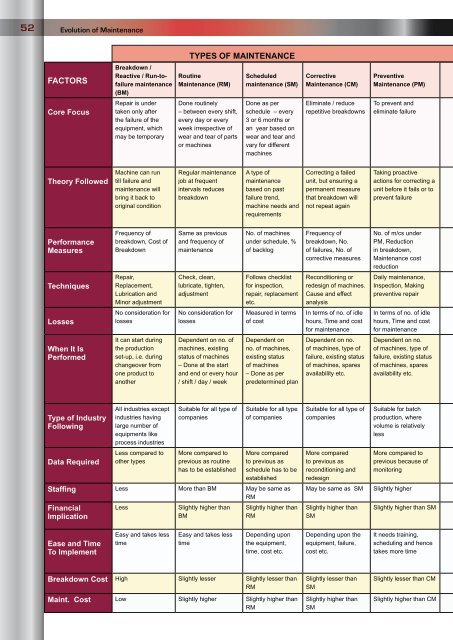

Evolution of Maintenance51 To reduce overall equipment emergencies To reduce maintenance purchasing To provide a systematic approach for improving the efficiency of the production system by eliminating all losses To develop equipment, which are designed for maintainability and reliability to realize reduced life cycle cost To assure a good product quality through investigation, analysis and improvement of process, material andequipment conditions To aid in achieving zero accidents in a healthy and clean work environment and protect the natural environment To develop a flexible, multi-skilled organization with internal experts To optimise the maintenance cost and provide better services to operations through computer integratedmaintenance management systems (CIMMS), teamwork, use of latest tools and technologies etc.Comparison of various maintenance systemsThe various maintenance systems were compared and it is shown in Table 3. Different parameters have beenused for comparison and based on this comparison; it was found that, each of the maintenance systems hasits own advantages and disadvantages. It should be noted that no single maintenance systems is followed,but a combination of maintenance systems are followed in industries. Further the type of maintenance systemadopted by an organization depends on various factors and the important factors include type and cost ofmachine, type of process, product etc. Hence the objective of this comparison is to provide the practitionerswith a ready reference regarding different maintenance systems and thereby describe its characteristics in anutshell.ConclusionsIn this paper, different maintenance systems were described. In addition to this, a comparative analysis ofdifferent types of maintenance systems was carried out considering various factors. From the analysis, it wasevident that traditional maintenance systems such as breakdown or preventive or predictive maintenance etc.are not capable of satisfying the requirements of present day manufacturing systems and it was concluded thatthe present system of TPM needs to pave the way for the system called WMS.ReferencesBevilacqua, M & Braglia, M (2000),“The analytic hierarchy process applied to maintenance strategy selection”, Reliability Eng. & System Safety, Vol70 No1, pp. 71–83.Chan, F.T.S., Lau, H.C.W., Ip, R.W.L., Chan, H.K., Kong, S. (2005), “Implementation of total productive maintenance: A case study”,International Journal of Production Economics, Vol.95, No.1, pp.71-94Duffuaa S., Raouf A., Campbell J. D. (1999), Planning and Control of Maintenance Systems, Modelling and Analysis, John Wiley & Sons,Eade, R. (1997), “The importance of predictive maintenance”, Iron Age New Steel, Vol. 13 No. 9, pp. 68-72.Ettkin, L.P., & Jahnig, D.G. (1986), “Adapting MRPII for maintenance resource management can provide a strategic advantage”, Industrial Engineering, Vol.18 No.8, pp.50-59.Gallimore, K. and Penlesky, R. (1988), “A framework for developing maintenance strategies”, Production and Inventory Management Journal, Vol. 29 No. 1, pp. 16-22.Ingalls, P. (2002),”Just What is world class maintenance?”, available at: http://www.mt-online.com/articles/0205viewpoint.cfm, accessed on 10 March 2005.Ireland, F. and Dale, B. G. (2001), “A study of total productive maintenance implementation”, Journal of Quality in Maintenance Engineering, Vol. 7 No. 3, pp. 183-191.Jones, R.B. (1997), Risk-based Management, Jaico Publishing House, Mumbai.Labib, A. W. (1998), “World-class maintenance using a computerized maintenance management system”, Journal of Quality in Maintenance Engineering, Vol. 4, pp. 66-75.Mostafa, S.I. (2004), “Implementation of proactive maintenance in the Egyptian glass company”, Journal of Quality in Maintenance Engineering, Vol.10 No. 2, pp.107-122.Moubray, J. (1997), Reliability Centred Maintenance, 2nd edition, Industrial Press, New York.Nagarrur, N.N. (1999), “An object-oriented decision support system for maintenance management”, Journal of Quality in Maintenance Engineering, Vol. 5 No. 3, pp. 248-57.Nakajima, S. (1989), Total Productive Maintenance Development Program: Implementing Total Productive Maintenance, Productivity Press, Massachusetts.Oyebisi, T.O. (2000), “On reliability and maintenance management of electronic equipment in the tropics” Technovation, Vol. 20 No.9, pp. 517–522.Pintelon, L. and Waeyenbergh, G. (1999), “A practical approach to maintenance modelling”Ashayeri, W.G. Sullivan, M. M. Ahmad (Eds.), Flexible Automation and Intelligent Manufacturing, Begell House Inc., New York, pp. 1109–1119.Waeyenbergh, G. & Pintelon, L. (2002), “A framework for maintenance concept development”, International Journal of Production Economics, Vol. 77 No. 3, pp. 299–313.Wang, F. K. and Lee W. (2001), “Learning curve analysis in total productive maintenance”, International Journal of Management Science, Vol. 29 No.6, pp. 491-499.Weinstein, L., and Chung, C. H., (1999), “Integrating maintenance and production decisions in a hierarchical production planningenvironment”, Computers & Operations Research, Vol. 26 No.10/11, pp. 1059-1074.Wireman, T. (1991), World Class Maintenance Management, Industrial Press Inc., New York.Vol 21 No 23<strong>AMMJ</strong>

52Evolution of MaintenanceTYPES OF MAINTENANCEFACTORSBreakdown /Reactive / Run-tofailuremaintenance(BM)RoutineMaintenance (RM)Scheduledmaintenance (SM)CorrectiveMaintenance (CM)PreventiveMaintenance (PM)Core FocusRepair is undertaken only afterthe failure of theequipment, whichmay be temporaryDone routinely– between every shift,every day or everyweek irrespective ofwear and tear of partsor machinesDone as perschedule – every3 or 6 months oran year based onwear and tear andvary for differentmachinesEliminate / reducerepetitive breakdownsTo prevent andeliminate failureTheory FollowedMachine can runtill failure andmaintenance willbring it back tooriginal conditionRegular maintenancejob at frequentintervals reducesbreakdownA type ofmaintenancebased on pastfailure trend,machine needs andrequirementsCorrecting a failedunit, but ensuring apermanent measurethat breakdown willnot repeat againTaking proactiveactions for correcting aunit before it fails or toprevent failurePerformanceMeasuresFrequency ofbreakdown, Cost ofBreakdownSame as previousand frequency ofmaintenanceNo. of machinesunder schedule, %of backlogFrequency ofbreakdown, No.of failures, No. ofcorrective measuresNo. of m/cs underPM, Reductionin breakdown,Maintenance costreductionTechniquesRepair,Replacement,Lubrication andMinor adjustmentCheck, clean,lubricate, tighten,adjustmentFollows checklistfor inspection,repair, replacementetc.Reconditioning orredesign of machines.Cause and effectanalysisDaily maintenance,Inspection, Makingpreventive repairLossesNo consideration forlossesNo consideration forlossesMeasured in termsof costIn terms of no. of idlehours, Time and costfor maintenanceIn terms of no. of idlehours, Time and costfor maintenanceWhen It IsPerformedIt can start duringthe productionset-up, i.e. duringchangeover fromone product toanotherDependent on no. ofmachines, existingstatus of machines– Done at the startand end or every hour/ shift / day / weekDependent onno. of machines,existing statusof machines– Done as perpredetermined planDependent on no.of machines, type offailure, existing statusof machines, sparesavailability etc.Dependent on no.of machines, type offailure, existing statusof machines, sparesavailability etc.Type of IndustryFollowingData RequiredAll industries exceptindustries havinglarge number ofequipments likeprocess industriesLess compared toother typesSuitable for all type ofcompaniesMore compared toprevious as routinehas to be establishedSuitable for all typeof companiesMore comparedto previous asschedule has to beestablishedStaffing Less More than BM May be same asRMFinancialImplicationLessSlightly higher thanBMSlightly higher thanRMSuitable for all type ofcompaniesMore comparedto previous asreconditioning andredesignMay be same as SMSlightly higher thanSMSuitable for batchproduction, wherevolume is relativelylessMore compared toprevious because ofmonitoringSlightly higherSlightly higher than SMEase and TimeTo ImplementEasy and takes lesstimeEasy and takes lesstimeDepending uponthe equipment,time, cost etc.Depending upon theequipment, failure,cost etc.It needs training,scheduling and hencetakes more timeBreakdown Cost High Slightly lesser Slightly lesser thanRMMaint. Cost Low Slightly higher Slightly higher thanRMSlightly lesser thanSMSlightly higher thanSMSlightly lesser than CMSlightly higher than CM