PALSUN Technical Guide

PALSUN Technical Guide

PALSUN Technical Guide

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

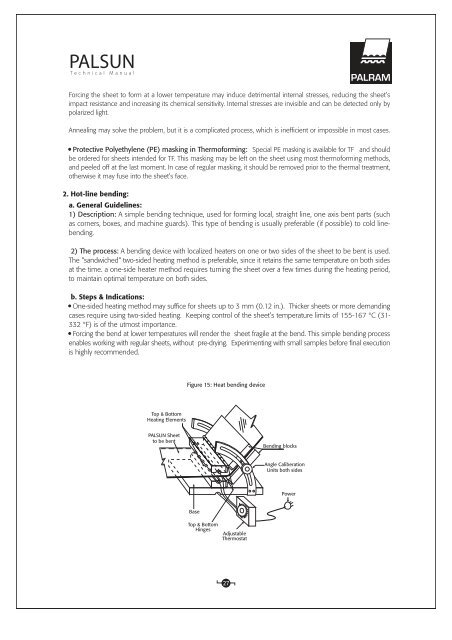

<strong>PALSUN</strong><strong>Technical</strong> ManualForcing the sheet to form at a lower temperature may induce detrimental internal stresses, reducing the sheet’simpact resistance and increasing its chemical sensitivity. Internal stresses are invisible and can be detected only bypolarized light.Annealing may solve the problem, but it is a complicated process, which is inefficient or impossible in most cases.Protective Polyethylene (PE) masking in Thermoforming: Special PE masking is available for TF and shouldbe ordered for sheets intended for TF. This masking may be left on the sheet using most thermoforming methods,and peeled off at the last moment. In case of regular masking, it should be removed prior to the thermal treatment,otherwise it may fuse into the sheet’s face.2. Hot-line bending:a. General <strong>Guide</strong>lines:1) Description: A simple bending technique, used for forming local, straight line, one axis bent parts (suchas corners, boxes, and machine guards). This type of bending is usually preferable (if possible) to cold linebending.2) The process: A bending device with localized heaters on one or two sides of the sheet to be bent is used.The “sandwiched“ two-sided heating method is preferable, since it retains the same temperature on both sidesat the time. a one-side heater method requires turning the sheet over a few times during the heating period,to maintain optimal temperature on both sides.b. Steps & Indications:One-sided heating method may suffice for sheets up to 3 mm (0.12 in.). Thicker sheets or more demandingcases require using two-sided heating. Keeping control of the sheet’s temperature limits of 155-167 °C (31-332 °F) is of the utmost importance.Forcing the bend at lower temperatures will render the sheet fragile at the bend. This simple bending processenables working with regular sheets, without pre-drying. Experimenting with small samples before final executionis highly recommended.Figure 15: Heat bending deviceTop & BottomHeating Elements<strong>PALSUN</strong> Sheetto be bentBending blocksAngle CaliberationUnits both sidesPowerBaseTop & BottomHingesAdjustableThermostat27