PALSUN Technical Guide

PALSUN Technical Guide

PALSUN Technical Guide

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

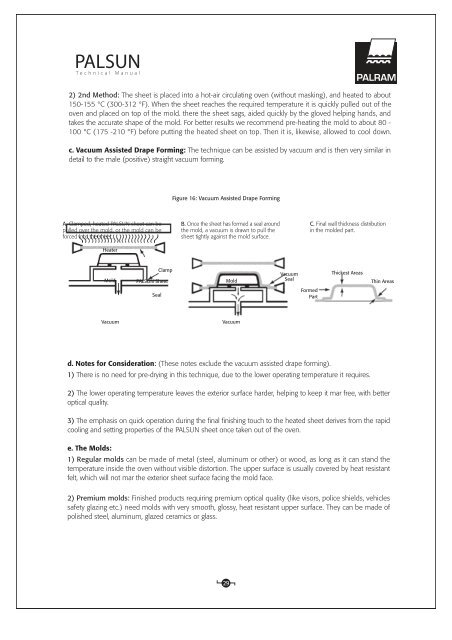

<strong>PALSUN</strong><strong>Technical</strong> Manual2) 2nd Method: The sheet is placed into a hot-air circulating oven (without masking), and heated to about150-155 °C (300-312 °F). When the sheet reaches the required temperature it is quickly pulled out of theoven and placed on top of the mold. there the sheet sags, aided quickly by the gloved helping hands, andtakes the accurate shape of the mold. For better results we recommend pre-heating the mold to about 80 -100 °C (175 -210 °F) before putting the heated sheet on top. Then it is, likewise, allowed to cool down.c. Vacuum Assisted Drape Forming: The technique can be assisted by vacuum and is then very similar indetail to the male (positive) straight vacuum forming.Figure 16: Vacuum Assisted Drape FormingA. Clamped, heated <strong>PALSUN</strong> sheet can bepulled over the mold, or the mold can beforced into the sheet.HeaterB. Once the sheet has formed a seal aroundthe mold, a vacuum is drawn to pull thesheet tightly against the mold surface.C. Final wall thickness distributionin the molded part.MoldClamp<strong>PALSUN</strong> SheetMoldVacuumSealThickest AreasThin AreasSealFormedPartVacuumVacuumd. Notes for Consideration: (These notes exclude the vacuum assisted drape forming).1) There is no need for pre-drying in this technique, due to the lower operating temperature it requires.2) The lower operating temperature leaves the exterior surface harder, helping to keep it mar free, with betteroptical quality.3) The emphasis on quick operation during the final finishing touch to the heated sheet derives from the rapidcooling and setting properties of the <strong>PALSUN</strong> sheet once taken out of the oven.e. The Molds:1) Regular molds can be made of metal (steel, aluminum or other) or wood, as long as it can stand thetemperature inside the oven without visible distortion. The upper surface is usually covered by heat resistantfelt, which will not mar the exterior sheet surface facing the mold face.2) Premium molds: Finished products requiring premium optical quality (like visors, police shields, vehiclessafety glazing etc.) need molds with very smooth, glossy, heat resistant upper surface. They can be made ofpolished steel, aluminum, glazed ceramics or glass.29