PALSUN Technical Guide

PALSUN Technical Guide

PALSUN Technical Guide

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

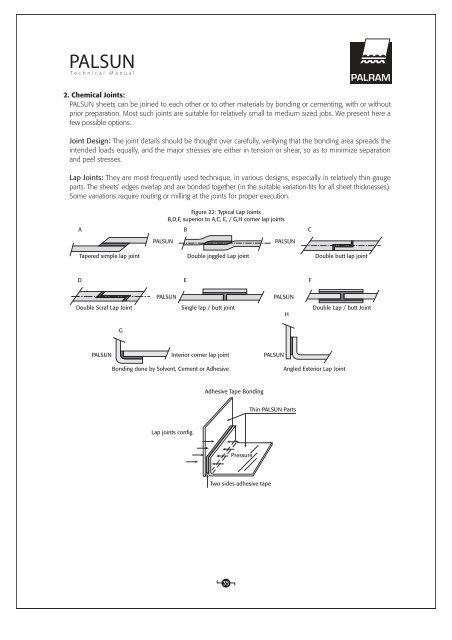

<strong>PALSUN</strong><strong>Technical</strong> Manual2. Chemical Joints:<strong>PALSUN</strong> sheets can be joined to each other or to other materials by bonding or cementing, with or withoutprior preparation. Most such joints are suitable for relatively small to medium sized jobs. We present here afew possible options:Joint Design: The joint details should be thought over carefully, verifying that the bonding area spreads theintended loads equally, and the major stresses are either in tension or shear, so as to minimize separationand peel stresses.Lap Joints: They are most frequently used technique, in various designs, especially in relatively thin gaugeparts. The sheets’ edges overlap and are bonded together (in the suitable variation-fits for all sheet thicknesses).Some variations require routing or milling at the joints for proper execution.AFigure 22: Typical Lap JointsB,D,F, superior to A,C, E, / G,H corner lap jointsBC<strong>PALSUN</strong><strong>PALSUN</strong>Tapered simple lap jointDouble joggled Lap jointDouble butt lap jointDEF<strong>PALSUN</strong><strong>PALSUN</strong>Double Scraf Lap JointSingle lap / butt jointHDouble Lap / butt JointG<strong>PALSUN</strong>Interior corner lap jointBonding done by Solvent, Cement or Adhesive<strong>PALSUN</strong>Angled Exterior Lap JointAdhesive Tape BondingThin <strong>PALSUN</strong> PartsLap joints config.PressureTwo sides adhesive tape35