Safety_Series_015_1965 - gnssn - International Atomic Energy ...

Safety_Series_015_1965 - gnssn - International Atomic Energy ...

Safety_Series_015_1965 - gnssn - International Atomic Energy ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

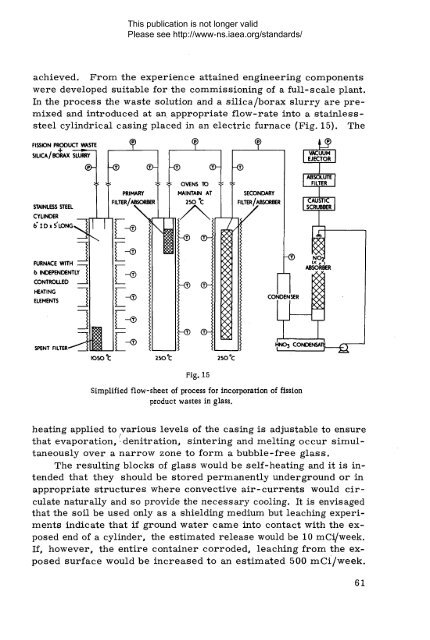

This publication is not longer validPlease see http://www-ns.iaea.org/standards/achieved. From the experience attained engineering componentswere developed suitable for the commissioning of a full-scale plant.In the process the waste solution and a silica/borax slurry are premixedand introduced at an appropriate flow-rate into a stainlesssteelcylindrical casing placed in an electric furnace (Fig. 15). TheFISSION PRODUCT WASTESILICA/BORAX SLURRY-© ©-STAINLESS STEELCYLINDER6* I D » 5'LONGT 5PRIMARYfilter/absorber; TFURNACE WITH — .6 INDEPENDENTLY \CONTROLLED __ iHEATINGELEMENTSFig. 15Sim plified flow -sheet o f process for incorporation o f fissionproduct wastes in glass.heating applied to various levels of the casing is adjustable to ensurethat evaporation, ' denitration, sintering and melting occur simultaneouslyover a narrow zone to form a bubble-free glass.The resulting blocks of glass would be self-heating and it is intendedthat they should be stored permanently underground or inappropriate structures where convective air-currents would c ir culate naturally and so provide the necessary cooling. It is envisagedthat the soil be used only as a shielding medium but leaching experimentsindicate that if ground water came into contact with the exposedend of a cylinder, the estimated release would be 10 mCi/week.If, however, the entire container corroded, leaching from the exposedsurface would be increased to an estimated 500 m Ci/week.61