You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

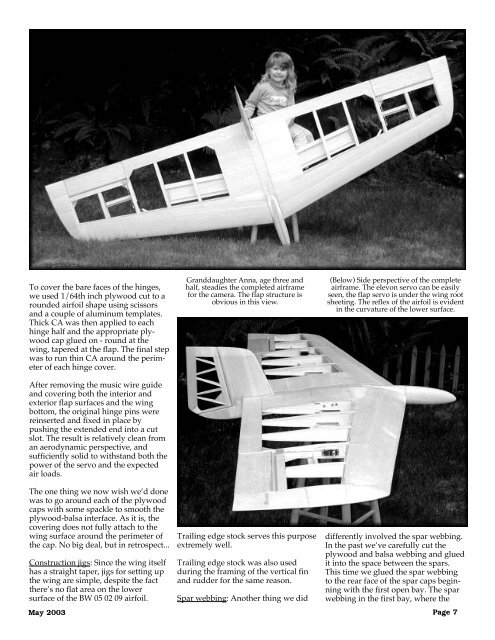

To cover the bare faces of the hinges,we used 1/64th inch plywood cut to arounded airfoil shape using scissorsand a couple of aluminum templates.Thick CA was then applied to eachhinge half and the appropriate plywoodcap glued on - round at thewing, tapered at the flap. The final stepwas to run thin CA around the perimeterof each hinge cover.After removing the music wire guideand covering both the interior andexterior flap surfaces and the wingbottom, the original hinge pins werereinserted and fixed in place bypushing the extended end into a cutslot. The result is relatively clean froman aerodynamic perspective, andsufficiently solid to withstand both thepower of the servo and the expectedair loads.The one thing we now wish we’d donewas to go around each of the plywoodcaps with some spackle to smooth theplywood-balsa interface. As it is, thecovering does not fully attach to thewing surface around the perimeter ofthe cap. No big deal, but in retrospect...Construction jigs: Since the wing itselfhas a straight taper, jigs for setting upthe wing are simple, despite the factthere’s no flat area on the lowersurface of the BW 05 02 09 airfoil.<strong>May</strong> 2003Granddaughter Anna, age three andhalf, steadies the <strong>com</strong>pleted airframefor the camera. The flap structure isobvious in this view.Trailing edge stock serves this purposeextremely well.Trailing edge stock was also usedduring the framing of the vertical finand rudder for the same reason.Spar webbing: Another thing we did(Below) Side perspective of the <strong>com</strong>pleteairframe. The elevon servo can be easilyseen, the flap servo is under the wing rootsheeting. The reflex of the airfoil is evidentin the curvature of the lower surface.differently involved the spar webbing.In the past we’ve carefully cut theplywood and balsa webbing and gluedit into the space between the spars.This time we glued the spar webbingto the rear face of the spar caps beginningwith the first open bay. The sparwebbing in the first bay, where thePage 7