You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

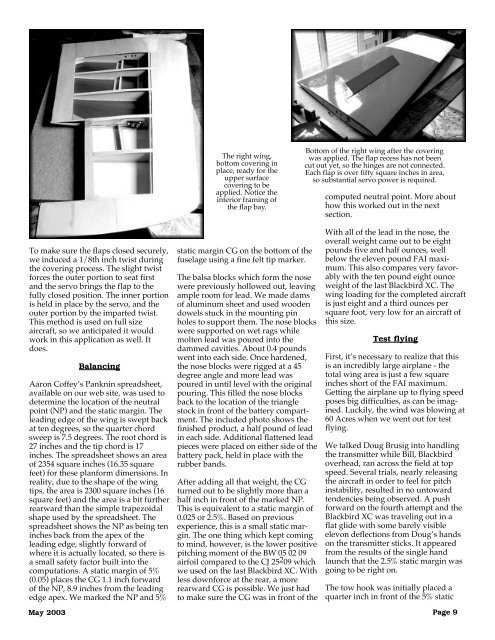

The right wing,bottom covering inplace, ready for theupper surfacecovering to beapplied. Notice theinterior framing ofthe flap bay.Bottom of the right wing after the coveringwas applied. The flap recess has not beencut out yet, so the hinges are not connected.Each flap is over fifty square inches in area,so substantial servo power is required.<strong>com</strong>puted neutral point. More abouthow this worked out in the nextsection.To make sure the flaps closed securely,we induced a 1/8th inch twist duringthe covering process. The slight twistforces the outer portion to seat firstand the servo brings the flap to thefully closed position. The inner portionis held in place by the servo, and theouter portion by the imparted twist.This method is used on full sizeaircraft, so we anticipated it wouldwork in this application as well. Itdoes.<strong>May</strong> 2003BalancingAaron Coffey’s Panknin spreadsheet,available on our web site, was used todetermine the location of the neutralpoint (NP) and the static margin. Theleading edge of the wing is swept backat ten degrees, so the quarter chordsweep is 7.5 degrees. The root chord is27 inches and the tip chord is 17inches. The spreadsheet shows an areaof 2354 square inches (16.35 squarefeet) for these planform dimensions. Inreality, due to the shape of the wingtips, the area is 2300 square inches (16square feet) and the area is a bit furtherrearward than the simple trapezoidalshape used by the spreadsheet. Thespreadsheet shows the NP as being teninches back from the apex of theleading edge, slightly forward ofwhere it is actually located, so there isa small safety factor built into the<strong>com</strong>putations. A static margin of 5%(0.05) places the CG 1.1 inch forwardof the NP, 8.9 inches from the leadingedge apex. We marked the NP and 5%static margin CG on the bottom of thefuselage using a fine felt tip marker.The balsa blocks which form the nosewere previously hollowed out, leavingample room for lead. We made damsof aluminum sheet and used woodendowels stuck in the mounting pinholes to support them. The nose blockswere supported on wet rags whilemolten lead was poured into thedammed cavities. About 0.4 poundswent into each side. Once hardened,the nose blocks were rigged at a 45degree angle and more lead waspoured in until level with the originalpouring. This filled the nose blocksback to the location of the trianglestock in front of the battery <strong>com</strong>partment.The included photo shows thefinished product, a half pound of leadin each side. Additional flattened leadpieces were placed on either side of thebattery pack, held in place with therubber bands.After adding all that weight, the CGturned out to be slightly more than ahalf inch in front of the marked NP.This is equivalent to a static margin of0.025 or 2.5%. Based on previousexperience, this is a small static margin.The one thing which kept <strong>com</strong>ingto mind, however, is the lower positivepitching moment of the BW 05 02 09airfoil <strong>com</strong>pared to the CJ 25 2 09 whichwe used on the last Blackbird XC. Withless downforce at the rear, a morerearward CG is possible. We just hadto make sure the CG was in front of theWith all of the lead in the nose, theoverall weight came out to be eightpounds five and half ounces, wellbelow the eleven pound FAI maximum.This also <strong>com</strong>pares very favorablywith the ten pound eight ounceweight of the last Blackbird XC. Thewing loading for the <strong>com</strong>pleted aircraftis just eight and a third ounces persquare foot, very low for an aircraft ofthis size.Test flyingFirst, it’s necessary to realize that thisis an incredibly large airplane - thetotal wing area is just a few squareinches short of the FAI maximum.Getting the airplane up to flying speedposes big difficulties, as can be imagined.Luckily, the wind was blowing at60 Acres when we went out for testflying.We talked Doug Brusig into handlingthe transmitter while Bill, Blackbirdoverhead, ran across the field at topspeed. Several trials, nearly releasingthe aircraft in order to feel for pitchinstability, resulted in no untowardtendencies being observed. A pushforward on the fourth attempt and theBlackbird XC was traveling out in aflat glide with some barely visibleelevon deflections from Doug’s handson the transmitter sticks. It appearedfrom the results of the single handlaunch that the 2.5% static margin wasgoing to be right on.The tow hook was initially placed aquarter inch in front of the 5% staticPage 9