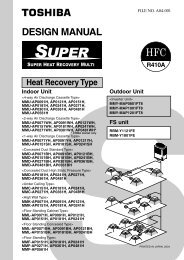

MCY-MAP0401HT MCY-MAP0501HT MCY-MAP0601HT ... - Toshiba

MCY-MAP0401HT MCY-MAP0501HT MCY-MAP0601HT ... - Toshiba

MCY-MAP0401HT MCY-MAP0501HT MCY-MAP0601HT ... - Toshiba

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

WARNINGInsulator checkVentilationBe attentive toelectric shockCompulsionAfter the work has finished, be sure to use an insulation tester set (500V mugger) tocheck the resistance is 2MΩ or more between the charge section and the non-chargemetal section (Earth position).If the resistance value is low, a disaster such as a leak or electric shock is caused at user’sside.When the refrigerant gas leaks during work, execute ventilation.If the refrigerant gas touches to a fire, poisonous gas generates. A case of leakage of therefrigerant and the closed room full with gas is dangerous because a shortage of oxygenoccurs. Be sure to execute ventilation.When checking the circuit inevitably under condition of the power-ON, use rubbergloves and others not to touch to the charging section.If touching to the charging section, an electric shock may be caused.When the refrigerant gas leaks, find up the leaked position and repair it surely.If the leaked position cannot be found up and the repair work is interrupted, pump-downand tighten the service valve, otherwise the refrigerant gas may leak into the room.The poisonous gas generates when gas touches to fire such as fan heater, stove or cockingstove though the refrigerant gas itself is innocuous.When installing equipment which includes a large amount of charged refrigerant suchas a multi air conditioner in a sub-room, it is necessary that the density does not thelimit even if the refrigerant leaks.If the refrigerant leaks and exceeds the limit density, an accident of shortage of oxygen iscaused.For the installation/moving/reinstallation work, follow to the Installation Manual.If an incorrect installation is done, a trouble of the refrigerating cycle, water leak, electricshock or fire is caused.After repair work has finished, check there is no trouble.If check is not executed, a fire, electric shock or injury may be caused. For a check, turn offthe power breaker.Check after rerairCheck after reinstallationAfter repair work (installation of front panel and cabinet) has finished, execute a testrun to check there is no generation of smoke or abnormal sound.If check is not executed, a fire or an electric shock is caused. Before test run, install thefront panel and cabinet.Check the following items after reinstallation.1) The earth wire is correctly connected.2) The power cord is not caught in the product.3) There is no inclination or unsteadiness and the installation is stable.If check is not executed, a fire, an electric shock or an injury is caused.CAUTIONPut on glovesCooling checkBe sure to put on gloves (∗) during repair work.If not putting on gloves, an injury may be caused with the parts, etc.(∗) Heavy gloves such as work glovesWhen the power was turned on, start to work after the equipment has beensufficiently cooled.As temperature of the compressor pipes and others became high due to cooling/heatingoperation, a burn may be caused.6