Diesel distributor fuel-injection pumps VE - K-Jet.org

Diesel distributor fuel-injection pumps VE - K-Jet.org

Diesel distributor fuel-injection pumps VE - K-Jet.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

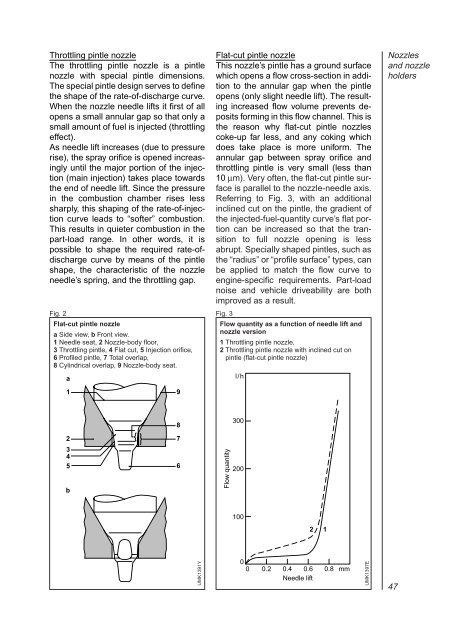

Throttling pintle nozzleThe throttling pintle nozzle is a pintlenozzle with special pintle dimensions.The special pintle design serves to definethe shape of the rate-of-discharge curve.When the nozzle needle lifts it first of allopens a small annular gap so that only asmall amount of <strong>fuel</strong> is injected (throttlingeffect).As needle lift increases (due to pressurerise), the spray orifice is opened increasinglyuntil the major portion of the <strong>injection</strong>(main <strong>injection</strong>) takes place towardsthe end of needle lift. Since the pressurein the combustion chamber rises lesssharply, this shaping of the rate-of-<strong>injection</strong>curve leads to “softer” combustion.This results in quieter combustion in thepart-load range. In other words, it ispossible to shape the required rate-ofdischargecurve by means of the pintleshape, the characteristic of the nozzleneedle’s spring, and the throttling gap.Fig. 2Flat-cut pintle nozzlea Side view, b Front view.1 Needle seat, 2 Nozzle-body floor,3 Throttling pintle, 4 Flat cut, 5 Injection orifice,6 Profiled pintle, 7 Total overlap,8 Cylindrical overlap, 9 Nozzle-body seat.aFlat-cut pintle nozzleThis nozzle’s pintle has a ground surfacewhich opens a flow cross-section in additionto the annular gap when the pintleopens (only slight needle lift). The resultingincreased flow volume prevents depositsforming in this flow channel. This isthe reason why flat-cut pintle nozzlescoke-up far less, and any coking whichdoes take place is more uniform. Theannular gap between spray orifice andthrottling pintle is very small (less than10 µm). Very often, the flat-cut pintle surfaceis parallel to the nozzle-needle axis.Referring to Fig. 3, with an additionalinclined cut on the pintle, the gradient ofthe injected-<strong>fuel</strong>-quantity curve’s flat portioncan be increased so that the transitionto full nozzle opening is lessabrupt. Specially shaped pintles, such asthe “radius” or “profile surface” types, canbe applied to match the flow curve toengine-specific requirements. Part-loadnoise and vehicle driveability are bothimproved as a result.Fig. 3Flow quantity as a function of needle lift andnozzle version1 Throttling pintle nozzle,2 Throttling pintle nozzle with inclined cut onpintle (flat-cut pintle nozzle)l/hNozzlesand nozzleholders19830027345b6Flow quantity2001002 1UMK1391Y00 0.20.4 0.6 0.8 mmNeedle liftUMK1397E47