Diesel distributor fuel-injection pumps VE - K-Jet.org

Diesel distributor fuel-injection pumps VE - K-Jet.org

Diesel distributor fuel-injection pumps VE - K-Jet.org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

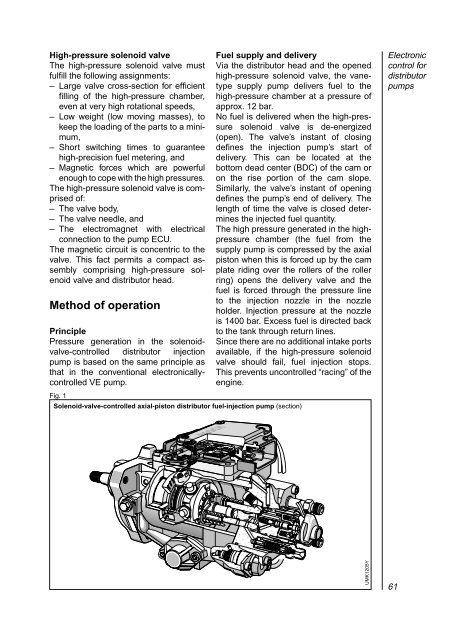

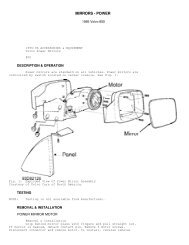

High-pressure solenoid valveThe high-pressure solenoid valve mustfulfill the following assignments:– Large valve cross-section for efficientfilling of the high-pressure chamber,even at very high rotational speeds,– Low weight (low moving masses), tokeep the loading of the parts to a minimum,– Short switching times to guaranteehigh-precision <strong>fuel</strong> metering, and– Magnetic forces which are powerfulenough to cope with the high pressures.The high-pressure solenoid valve is comprisedof:– The valve body,– The valve needle, and– The electromagnet with electricalconnection to the pump ECU.The magnetic circuit is concentric to thevalve. This fact permits a compact assemblycomprising high-pressure solenoidvalve and <strong>distributor</strong> head.Method of operationPrinciplePressure generation in the solenoidvalve-controlled<strong>distributor</strong> <strong>injection</strong>pump is based on the same principle asthat in the conventional electronicallycontrolled<strong>VE</strong> pump.Fig. 1Fuel supply and deliveryVia the <strong>distributor</strong> head and the openedhigh-pressure solenoid valve, the vanetypesupply pump delivers <strong>fuel</strong> to thehigh-pressure chamber at a pressure ofapprox. 12 bar.No <strong>fuel</strong> is delivered when the high-pressuresolenoid valve is de-energized(open). The valve’s instant of closingdefines the <strong>injection</strong> pump’s start ofdelivery. This can be located at thebottom dead center (BDC) of the cam oron the rise portion of the cam slope.Similarly, the valve’s instant of openingdefines the pump’s end of delivery. Thelength of time the valve is closed determinesthe injected <strong>fuel</strong> quantity.The high pressure generated in the highpressurechamber (the <strong>fuel</strong> from thesupply pump is compressed by the axialpiston when this is forced up by the camplate riding over the rollers of the rollerring) opens the delivery valve and the<strong>fuel</strong> is forced through the pressure lineto the <strong>injection</strong> nozzle in the nozzleholder. Injection pressure at the nozzleis 1400 bar. Excess <strong>fuel</strong> is directed backto the tank through return lines.Since there are no additional intake portsavailable, if the high-pressure solenoidvalve should fail, <strong>fuel</strong> <strong>injection</strong> stops.This prevents uncontrolled “racing” of theengine.Solenoid-valve-controlled axial-piston <strong>distributor</strong> <strong>fuel</strong>-<strong>injection</strong> pump (section)Electroniccontrol for<strong>distributor</strong><strong>pumps</strong>UMK1205Y61