Diesel distributor fuel-injection pumps VE - K-Jet.org

Diesel distributor fuel-injection pumps VE - K-Jet.org

Diesel distributor fuel-injection pumps VE - K-Jet.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

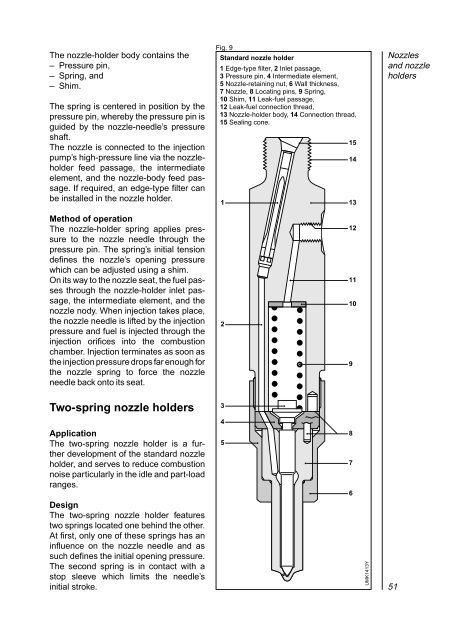

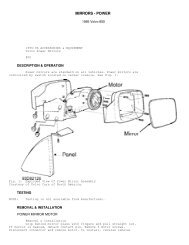

The nozzle-holder body contains the– Pressure pin,– Spring, and– Shim.The spring is centered in position by thepressure pin, whereby the pressure pin isguided by the nozzle-needle’s pressureshaft.The nozzle is connected to the <strong>injection</strong>pump’s high-pressure line via the nozzleholderfeed passage, the intermediateelement, and the nozzle-body feed passage.If required, an edge-type filter canbe installed in the nozzle holder.Fig. 9Standard nozzle holder1 Edge-type filter, 2 Inlet passage,3 Pressure pin, 4 Intermediate element,5 Nozzle-retaining nut, 6 Wall thickness,7 Nozzle, 8 Locating pins, 9 Spring,10 Shim, 11 Leak-<strong>fuel</strong> passage,12 Leak-<strong>fuel</strong> connection thread,13 Nozzle-holder body, 14 Connection thread,15 Sealing cone.1151413Nozzlesand nozzleholdersMethod of operationThe nozzle-holder spring applies pressureto the nozzle needle through thepressure pin. The spring’s initial tensiondefines the nozzle’s opening pressurewhich can be adjusted using a shim.On its way to the nozzle seat, the <strong>fuel</strong> passesthrough the nozzle-holder inlet passage,the intermediate element, and thenozzle nody. When <strong>injection</strong> takes place,the nozzle needle is lifted by the <strong>injection</strong>pressure and <strong>fuel</strong> is injected through the<strong>injection</strong> orifices into the combustionchamber. Injection terminates as soon asthe <strong>injection</strong> pressure drops far enough forthe nozzle spring to force the nozzleneedle back onto its seat.21211109Two-spring nozzle holdersApplicationThe two-spring nozzle holder is a furtherdevelopment of the standard nozzleholder, and serves to reduce combustionnoise particularly in the idle and part-loadranges.DesignThe two-spring nozzle holder featurestwo springs located one behind the other.At first, only one of these springs has aninfluence on the nozzle needle and assuch defines the initial opening pressure.The second spring is in contact with astop sleeve which limits the needle’sinitial stroke.345876UMK1413Y51