Diaphragm Design Manual - Simrit

Diaphragm Design Manual - Simrit

Diaphragm Design Manual - Simrit

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

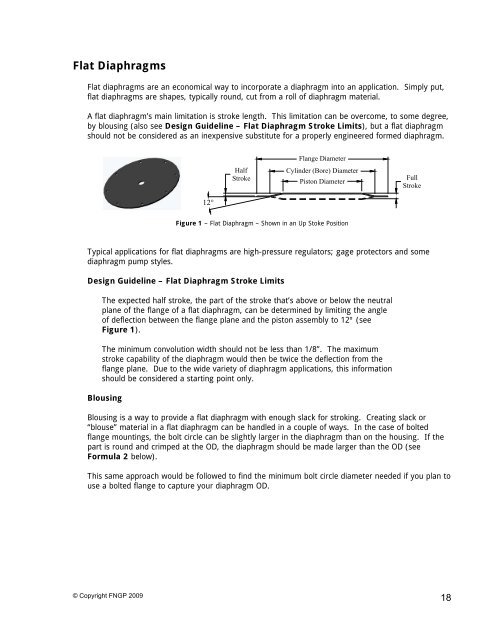

Flat <strong>Diaphragm</strong>sFlat diaphragms are an economical way to incorporate a diaphragm into an application. Simply put,flat diaphragms are shapes, typically round, cut from a roll of diaphragm material.A flat diaphragm’s main limitation is stroke length. This limitation can be overcome, to some degree,by blousing (also see <strong>Design</strong> Guideline – Flat <strong>Diaphragm</strong> Stroke Limits), but a flat diaphragmshould not be considered as an inexpensive substitute for a properly engineered formed diaphragm.HalfStrokeFlange DiameterCylinder (Bore) DiameterPiston DiameterFullStroke12°Figure 1 – Flat <strong>Diaphragm</strong> – Shown in an Up Stoke PositionTypical applications for flat diaphragms are high-pressure regulators; gage protectors and somediaphragm pump styles.<strong>Design</strong> Guideline – Flat <strong>Diaphragm</strong> Stroke LimitsThe expected half stroke, the part of the stroke that’s above or below the neutralplane of the flange of a flat diaphragm, can be determined by limiting the angleof deflection between the flange plane and the piston assembly to 12º (seeFigure 1).The minimum convolution width should not be less than 1/8”. The maximumstroke capability of the diaphragm would then be twice the deflection from theflange plane. Due to the wide variety of diaphragm applications, this informationshould be considered a starting point only.BlousingBlousing is a way to provide a flat diaphragm with enough slack for stroking. Creating slack or“blouse” material in a flat diaphragm can be handled in a couple of ways. In the case of boltedflange mountings, the bolt circle can be slightly larger in the diaphragm than on the housing. If thepart is round and crimped at the OD, the diaphragm should be made larger than the OD (seeFormula 2 below).This same approach would be followed to find the minimum bolt circle diameter needed if you plan touse a bolted flange to capture your diaphragm OD.© Copyright FNGP 200918