Diaphragm Design Manual - Simrit

Diaphragm Design Manual - Simrit

Diaphragm Design Manual - Simrit

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

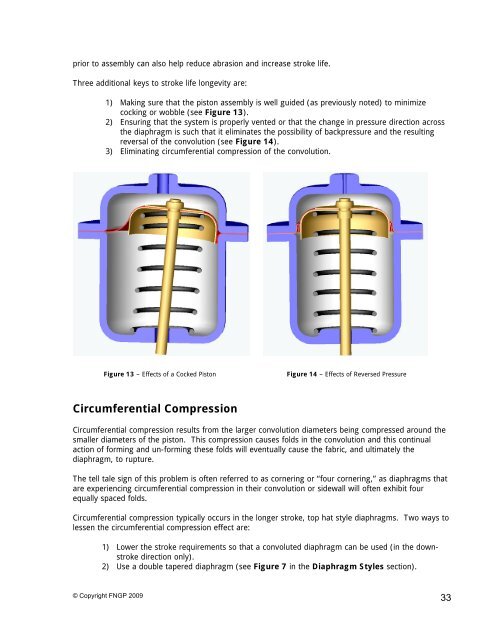

prior to assembly can also help reduce abrasion and increase stroke life.Three additional keys to stroke life longevity are:1) Making sure that the piston assembly is well guided (as previously noted) to minimizecocking or wobble (see Figure 13).2) Ensuring that the system is properly vented or that the change in pressure direction acrossthe diaphragm is such that it eliminates the possibility of backpressure and the resultingreversal of the convolution (see Figure 14).3) Eliminating circumferential compression of the convolution.Figure 13 – Effects of a Cocked PistonFigure 14 – Effects of Reversed PressureCircumferential CompressionCircumferential compression results from the larger convolution diameters being compressed around thesmaller diameters of the piston. This compression causes folds in the convolution and this continualaction of forming and un-forming these folds will eventually cause the fabric, and ultimately thediaphragm, to rupture.The tell tale sign of this problem is often referred to as cornering or “four cornering,” as diaphragms thatare experiencing circumferential compression in their convolution or sidewall will often exhibit fourequally spaced folds.Circumferential compression typically occurs in the longer stroke, top hat style diaphragms. Two ways tolessen the circumferential compression effect are:1) Lower the stroke requirements so that a convoluted diaphragm can be used (in the downstrokedirection only).2) Use a double tapered diaphragm (see Figure 7 in the <strong>Diaphragm</strong> Styles section).© Copyright FNGP 200933