Technical handbook for the paddy rice postharvest industry in ...

Technical handbook for the paddy rice postharvest industry in ...

Technical handbook for the paddy rice postharvest industry in ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

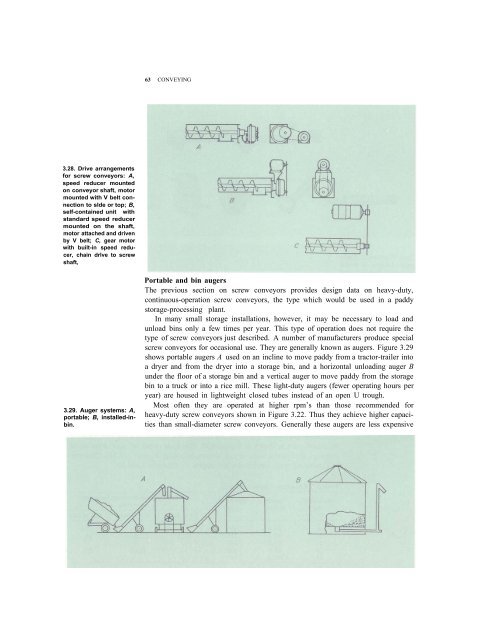

63 CONVEYING3.28. Drive arrangements<strong>for</strong> screw conveyors: A,speed reducer mountedon conveyor shaft, motormounted with V belt connectionto slde or top; B,self-conta<strong>in</strong>ed unit withstandard speed reducermounted on <strong>the</strong> shaft,motor attached and drivenby V belt; C, gear motorwith built-<strong>in</strong> speed reducer,cha<strong>in</strong> drlve to screwshaft,3.29. Auger systems: A,portable; B, <strong>in</strong>stalled-<strong>in</strong>b<strong>in</strong>.Portable and b<strong>in</strong> augersThe previous section on screw conveyors provides design data on heavy-duty,cont<strong>in</strong>uous-operation screw conveyors, <strong>the</strong> type which would be used <strong>in</strong> a <strong>paddy</strong>storage-process<strong>in</strong>g plant.In many small storage <strong>in</strong>stallations, however, it may be necessary to load andunload b<strong>in</strong>s only a few times per year. This type of operation does not require <strong>the</strong>type of screw conveyors just described. A number of manufacturers produce specialscrew conveyors <strong>for</strong> occasional use. They are generally known as augers. Figure 3.29shows portable augers A used on an <strong>in</strong>cl<strong>in</strong>e to move <strong>paddy</strong> from a tractor-trailer <strong>in</strong>toa dryer and from <strong>the</strong> dryer <strong>in</strong>to a storage b<strong>in</strong>, and a horizontal unload<strong>in</strong>g auger Bunder <strong>the</strong> floor of a storage b<strong>in</strong> and a vertical auger to move <strong>paddy</strong> from <strong>the</strong> storageb<strong>in</strong> to a truck or <strong>in</strong>to a <strong>rice</strong> mill. These light-duty augers (fewer operat<strong>in</strong>g hours peryear) are housed <strong>in</strong> lightweight closed tubes <strong>in</strong>stead of an open U trough.Most often <strong>the</strong>y are operated at higher rpm’s than those recommended <strong>for</strong>heavy-duty screw conveyors shown <strong>in</strong> Figure 3.22. Thus <strong>the</strong>y achieve higher capacitiesthan small-diameter screw conveyors. Generally <strong>the</strong>se augers are less expensive

![MNC_00_Modau [Compatibility Mode].pdf](https://img.yumpu.com/51432208/1/190x146/mnc-00-modau-compatibility-modepdf.jpg?quality=85)