Technical handbook for the paddy rice postharvest industry in ...

Technical handbook for the paddy rice postharvest industry in ...

Technical handbook for the paddy rice postharvest industry in ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

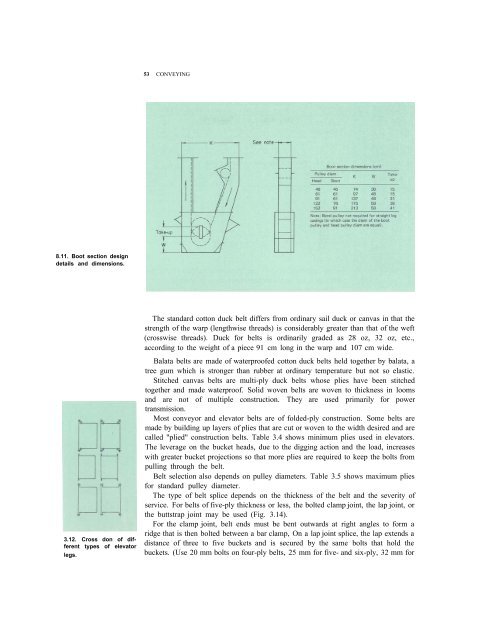

53 CONVEYING8.11. Boot section designdetails and dimensions.The standard cotton duck belt differs from ord<strong>in</strong>ary sail duck or canvas <strong>in</strong> that <strong>the</strong>strength of <strong>the</strong> warp (lengthwise threads) is considerably greater than that of <strong>the</strong> weft(crosswise threads). Duck <strong>for</strong> belts is ord<strong>in</strong>arily graded as 28 oz, 32 oz, etc.,accord<strong>in</strong>g to <strong>the</strong> weight of a piece 91 cm long <strong>in</strong> <strong>the</strong> warp and 107 cm wide.3.12. Cross don of differenttypes of elevatorlegs.Balata belts are made of waterproofed cotton duck belts held toge<strong>the</strong>r by balata, atree gum which is stronger than rubber at ord<strong>in</strong>ary temperature but not so elastic.Stitched canvas belts are multi-ply duck belts whose plies have been stitchedtoge<strong>the</strong>r and made waterproof. Solid woven belts are woven to thickness <strong>in</strong> loomsand are not of multiple construction. They are used primarily <strong>for</strong> powertransmission.Most conveyor and elevator belts are of folded-ply construction. Some belts aremade by build<strong>in</strong>g up layers of plies that are cut or woven to <strong>the</strong> width desired and arecalled "plied" construction belts. Table 3.4 shows m<strong>in</strong>imum plies used <strong>in</strong> elevators.The leverage on <strong>the</strong> bucket heads, due to <strong>the</strong> digg<strong>in</strong>g action and <strong>the</strong> load, <strong>in</strong>creaseswith greater bucket projections so that more plies are required to keep <strong>the</strong> bolts frompull<strong>in</strong>g through <strong>the</strong> belt.Belt selection also depends on pulley diameters. Table 3.5 shows maximum plies<strong>for</strong> standard pulley diameter.The type of belt splice depends on <strong>the</strong> thickness of <strong>the</strong> belt and <strong>the</strong> severity ofservice. For belts of five-ply thickness or less, <strong>the</strong> bolted clamp jo<strong>in</strong>t, <strong>the</strong> lap jo<strong>in</strong>t, or<strong>the</strong> buttstrap jo<strong>in</strong>t may be used (Fig. 3.14).For <strong>the</strong> clamp jo<strong>in</strong>t, belt ends must be bent outwards at right angles to <strong>for</strong>m aridge that is <strong>the</strong>n bolted between a bar clamp, On a lap jo<strong>in</strong>t splice, <strong>the</strong> lap extends adistance of three to five buckets and is secured by <strong>the</strong> same bolts that hold <strong>the</strong>buckets. (Use 20 mm bolts on four-ply belts, 25 mm <strong>for</strong> five- and six-ply, 32 mm <strong>for</strong>

![MNC_00_Modau [Compatibility Mode].pdf](https://img.yumpu.com/51432208/1/190x146/mnc-00-modau-compatibility-modepdf.jpg?quality=85)