Technical handbook for the paddy rice postharvest industry in ...

Technical handbook for the paddy rice postharvest industry in ...

Technical handbook for the paddy rice postharvest industry in ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

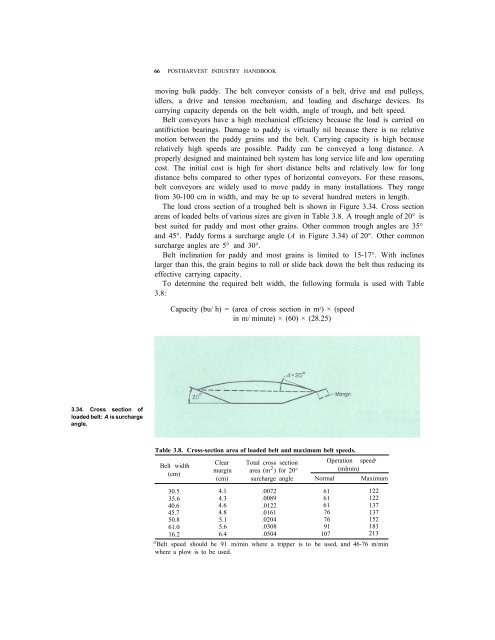

66 POSTHARVEST INDUSTRY HANDBOOKmov<strong>in</strong>g bulk <strong>paddy</strong>. The belt conveyor consists of a belt, drive and end pulleys,idlers, a drive and tension mechanism, and load<strong>in</strong>g and discharge devices. Itscarry<strong>in</strong>g capacity depends on <strong>the</strong> belt width, angle of trough, and belt speed.Belt conveyors have a high mechanical efficiency because <strong>the</strong> load is carried onantifriction bear<strong>in</strong>gs. Damage to <strong>paddy</strong> is virtually nil because <strong>the</strong>re is no relativemotion between <strong>the</strong> <strong>paddy</strong> gra<strong>in</strong>s and <strong>the</strong> belt. Carry<strong>in</strong>g capacity is high becauserelatively high speeds are possible. Paddy can be conveyed a long distance. Aproperly designed and ma<strong>in</strong>ta<strong>in</strong>ed belt system has long service life and low operat<strong>in</strong>gcost. The <strong>in</strong>itial cost is high <strong>for</strong> short distance belts and relatively low <strong>for</strong> longdistance belts compared to o<strong>the</strong>r types of horizontal conveyors. For <strong>the</strong>se reasons,belt conveyors are widely used to move <strong>paddy</strong> <strong>in</strong> many <strong>in</strong>stallations. They rangefrom 30-100 cm <strong>in</strong> width, and may be up to several hundred meters <strong>in</strong> length.The load cross section of a troughed belt is shown <strong>in</strong> Figure 3.34. Cross sectionareas of loaded belts of various sizes are given <strong>in</strong> Table 3.8. A trough angle of 20° isbest suited <strong>for</strong> <strong>paddy</strong> and most o<strong>the</strong>r gra<strong>in</strong>s. O<strong>the</strong>r common trough angles are 35°and 45°. Paddy <strong>for</strong>ms a surcharge angle ( A <strong>in</strong> Figure 3.34) of 20°. O<strong>the</strong>r commonsurcharge angles are 5° and 30°.Belt <strong>in</strong>cl<strong>in</strong>ation <strong>for</strong> <strong>paddy</strong> and most gra<strong>in</strong>s is limited to 15-17°. With <strong>in</strong>cl<strong>in</strong>eslarger than this, <strong>the</strong> gra<strong>in</strong> beg<strong>in</strong>s to roll or slide back down <strong>the</strong> belt thus reduc<strong>in</strong>g itseffective carry<strong>in</strong>g capacity.To determ<strong>in</strong>e <strong>the</strong> required belt width, <strong>the</strong> follow<strong>in</strong>g <strong>for</strong>mula is used with Table3.8:Capacity (bu/ h) = (area of cross section <strong>in</strong> m 2 ) × (speed<strong>in</strong> m/ m<strong>in</strong>ute) × (60) × (28.25)3.34. Cross section ofloaded belt: A is surchargeangle.Table 3.8. Cross-section area of loaded belt and maximum belt speeds.Belt width(cm)30.535.640.645.750.861.016.2Clear Total cross section Operation speed amarg<strong>in</strong> area (m 2 ) <strong>for</strong> 20° (mlm<strong>in</strong>)(cm) surcharge angle Normal Maximum4.14.34.64.85.15.66.4.0072.0089.0122.0161.0204.0308.0504616161767691107122122137137152183213a Belt speed should be 91 m/m<strong>in</strong> where a tripper is to be used, and 46-76 m/m<strong>in</strong>where a plow is to be used.

![MNC_00_Modau [Compatibility Mode].pdf](https://img.yumpu.com/51432208/1/190x146/mnc-00-modau-compatibility-modepdf.jpg?quality=85)