Technical handbook for the paddy rice postharvest industry in ...

Technical handbook for the paddy rice postharvest industry in ...

Technical handbook for the paddy rice postharvest industry in ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

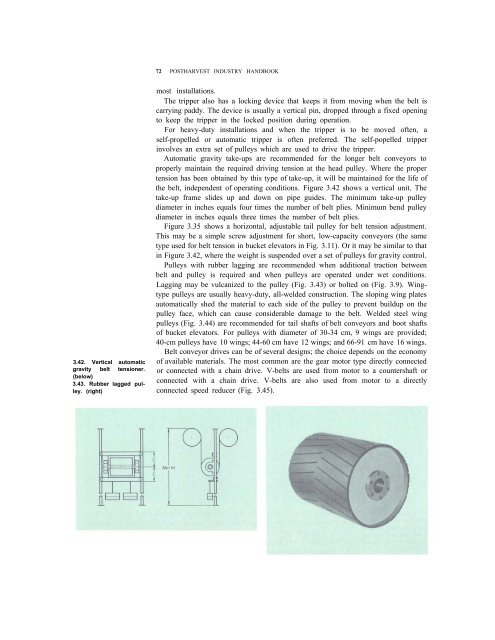

72 POSTHARVEST INDUSTRY HANDBOOK3.42. Vertical automaticgravity belt tensioner.(below)3.43. Rubber lagged pulley.(right)most <strong>in</strong>stallations.The tripper also has a lock<strong>in</strong>g device that keeps it from mov<strong>in</strong>g when <strong>the</strong> belt iscarry<strong>in</strong>g <strong>paddy</strong>. The device is usually a vertical p<strong>in</strong>, dropped through a fixed open<strong>in</strong>gto keep <strong>the</strong> tripper <strong>in</strong> <strong>the</strong> locked position dur<strong>in</strong>g operation.For heavy-duty <strong>in</strong>stallations and when <strong>the</strong> tripper is to be moved often, aself-propelled or automatic tripper is often preferred. The self-popelled tripper<strong>in</strong>volves an extra set of pulleys which are used to drive <strong>the</strong> tripper.Automatic gravity take-ups are recommended <strong>for</strong> <strong>the</strong> longer belt conveyors toproperly ma<strong>in</strong>ta<strong>in</strong> <strong>the</strong> required driv<strong>in</strong>g tension at <strong>the</strong> head pulley. Where <strong>the</strong> propertension has been obta<strong>in</strong>ed by this type of take-up, it will be ma<strong>in</strong>ta<strong>in</strong>ed <strong>for</strong> <strong>the</strong> life of<strong>the</strong> belt, <strong>in</strong>dependent of operat<strong>in</strong>g conditions. Figure 3.42 shows a vertical unit. Thetake-up frame slides up and down on pipe guides. The m<strong>in</strong>imum take-up pulleydiameter <strong>in</strong> <strong>in</strong>ches equals four times <strong>the</strong> number of belt plies. M<strong>in</strong>imum bend pulleydiameter <strong>in</strong> <strong>in</strong>ches equals three times <strong>the</strong> number of belt plies.Figure 3.35 shows a horizontal, adjustable tail pulley <strong>for</strong> belt tension adjustment.This may be a simple screw adjustment <strong>for</strong> short, low-capacity conveyors (<strong>the</strong> sametype used <strong>for</strong> belt tension <strong>in</strong> bucket elevators <strong>in</strong> Fig. 3.11). Or it may be similar to that<strong>in</strong> Figure 3.42, where <strong>the</strong> weight is suspended over a set of pulleys <strong>for</strong> gravity control.Pulleys with rubber lagg<strong>in</strong>g are recommended when additional traction betweenbelt and pulley is required and when pulleys are operated under wet conditions.Lagg<strong>in</strong>g may be vulcanized to <strong>the</strong> pulley (Fig. 3.43) or bolted on (Fig. 3.9). W<strong>in</strong>gtypepulleys are usually heavy-duty, all-welded construction. The slop<strong>in</strong>g w<strong>in</strong>g platesautomatically shed <strong>the</strong> material to each side of <strong>the</strong> pulley to prevent buildup on <strong>the</strong>pulley face, which can cause considerable damage to <strong>the</strong> belt. Welded steel w<strong>in</strong>gpulleys (Fig. 3.44) are recommended <strong>for</strong> tail shafts of belt conveyors and boot shaftsof bucket elevators. For pulleys with diameter of 30-34 cm, 9 w<strong>in</strong>gs are provided;40-cm pulleys have 10 w<strong>in</strong>gs; 44-60 cm have 12 w<strong>in</strong>gs; and 66-91 cm have 16 w<strong>in</strong>gs.Belt conveyor drives can be of several designs; <strong>the</strong> choice depends on <strong>the</strong> economyof available materials. The most common are <strong>the</strong> gear motor type directly connectedor connected with a cha<strong>in</strong> drive. V-belts are used from motor to a countershaft orconnected with a cha<strong>in</strong> drive. V-belts are also used from motor to a directlyconnected speed reducer (Fig. 3.45).

![MNC_00_Modau [Compatibility Mode].pdf](https://img.yumpu.com/51432208/1/190x146/mnc-00-modau-compatibility-modepdf.jpg?quality=85)