Technical handbook for the paddy rice postharvest industry in ...

Technical handbook for the paddy rice postharvest industry in ...

Technical handbook for the paddy rice postharvest industry in ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

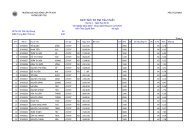

50 POSTHARVEST INDUSTRY HANDBOOK<strong>the</strong>n us<strong>in</strong>g 576 kg/m 3 <strong>for</strong> <strong>paddy</strong> and one metric ton as 1,000 kg:Elevator capacity (t/h) = (elevator capacity <strong>in</strong> m 3 /h) × (576 kg/m 3 ) ÷(1,000 kg/t).For example, take a 0.41 m head pulley with 127 × 89 mm buckets on 127 mmspac<strong>in</strong>g:m 3 /h = (.00056 cm) 1000/127 (65 m/m<strong>in</strong>ute) (60) = 17.2 m 3 /ht/h = (17.2) (576) ÷ 1000 = 10Table 3.3 shows representative capacities <strong>for</strong> various head pulleys at variousrpm's.Elevator head sectionElevator heads should be of <strong>the</strong> proper shape and size with smooth contours. Figure3.7 illustrates many of <strong>the</strong> design features that should be considered. The dischargeside of <strong>the</strong> head should be shaped so that material thrown from <strong>the</strong> buckets will notbe deflected <strong>in</strong>to <strong>the</strong> downleg. The throat should be considerably below <strong>the</strong> headshaft to catch materials that are slow leav<strong>in</strong>g <strong>the</strong> buckets. Head section dimensions<strong>for</strong> different size head pulleys are shown <strong>in</strong> Figure 3.8.Lagg<strong>in</strong>g on <strong>the</strong> elevator head pulley (Fig. 3.9) is needed <strong>in</strong> pull<strong>in</strong>g heavy loads.Proper lagg<strong>in</strong>g <strong>in</strong>creases <strong>the</strong> coefficient of friction between <strong>the</strong> pulley and belt. Ontall legs a backstop device is recommended to prevent <strong>the</strong> belt from runn<strong>in</strong>gbackwards when elevator cups are loaded and power is cut off. A simple mechanicalrachet device serves well as a backstop.The strut board at a 45° angle under <strong>the</strong> head pulley (Fig. 3.8) prevents <strong>the</strong>accumulation of <strong>paddy</strong> and dust.The throat plate should be easily replaceable so that it can be changed after itwears out. The head shaft must be heavy enough to resist bend<strong>in</strong>g and to provide <strong>the</strong>required torque carry<strong>in</strong>g capacity. It must stay level and properly l<strong>in</strong>ed up. Antifrictionbear<strong>in</strong>gs, properly lubricated, are recommended.Table 3.3. Average capacities of certa<strong>in</strong> elevators with different speeds and bucket sizes.Head pulleyBucketCapacity (t/h) with head pulley speed ofdiameterSize Spac<strong>in</strong>g56 51 46 42 31 34(mm)(mm) (mm)mm mm mm mm rpm rpm30 89 × 64102 × 7041 102 × 70127 × 89152 × 10251 152 × 102178 × 114203 × 12761 203 × 127229 × 152254 × 15276 254 × 152279 × 152305 × 17891 305 × 178356 × 178122 356 × 178356 × 2031021021021271521521651781782032032032032292292292292542.65.2––––––––––––––––31rpm– – – – – –– – – – – –6.3 – – – – –10.0 – – – – –12.5 – – – – –– 14.2 – – – –– 21.8 – – – –– 28.3 – – – –– – 31.0 – – –– – 42.7 – – –– – 46.6 – – –– – – 51.3 – –– – – 55.6 – –– – – 72.2 – –– – – – 79.4 –– – – – 96.2 –– – – – – 117.2– – – – – 137.6

![MNC_00_Modau [Compatibility Mode].pdf](https://img.yumpu.com/51432208/1/190x146/mnc-00-modau-compatibility-modepdf.jpg?quality=85)